One-time palletizing-burning tunnel kiln

A tunnel kiln and stack firing technology, which is applied in the production of furnace types, furnaces, ceramic materials, etc., can solve the problems of air duct corrosion and high maintenance costs, and achieve energy saving, stable and durable structure, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

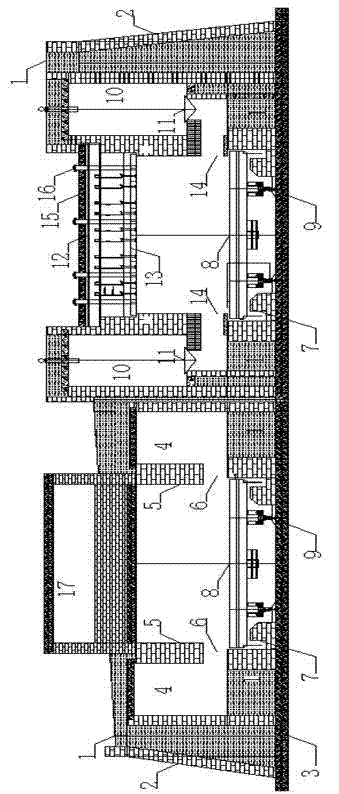

[0017] As shown in the figure, in the roasting kiln, the bricks carried by the kiln car 8 are burned in the roasting kiln, and the fan rotates to draw the hot flue gas to the roasting kiln exhaust duct 10 through the roasting kiln exhaust port 14, and the hot flue gas is transferred to the drying kiln by the fan The air supply channel 4 is blown to the wet bricks carried by the kiln car 8 through the drying kiln air supply port 6, and the moist air after drying the bricks is discharged to the outside of the kiln through the tide outlet 17, and the above process is repeated to continuously complete the burning of the bricks. system. The wind gate 11 cooperates with the centrifugal fan to adjust the air volume in the air duct, so as to achieve the purpose of producing high-quality sintered bricks with high efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com