Preparation method of 30MnSi steel billet

A technology of steel billet and molten steel, applied in the field of preparation of 30MnSi billet, can solve the problems of low purity of molten steel, low comprehensive qualification rate, low production efficiency, etc., so as to improve the purity and pourability, improve the quality of casting billet, and avoid alloying. The effect of component segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

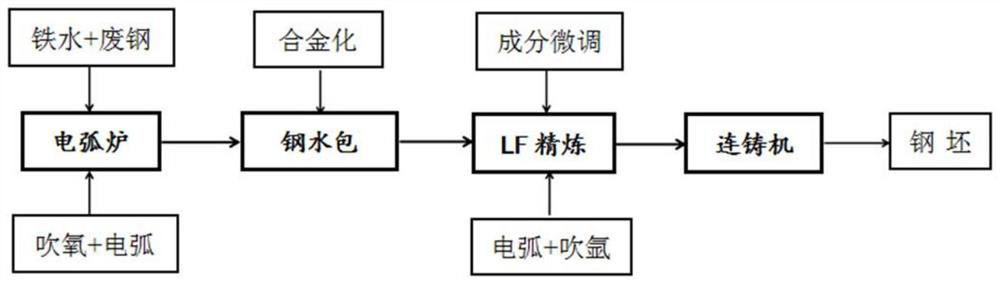

[0017] see figure 1 , the present invention provides an embodiment: a preparation method of a 30MnSi billet, the steps are:

[0018] Step 1: First add molten iron into the electric arc furnace, add scrap steel one after another at the beginning of smelting, add scrap steel in the middle of smelting, and smelt through 120t electric arc furnace of molten iron and scrap steel. stone as a slag-forming agent;

[0019] Step 2: Oxygen blowing smelting is carried out in an electric arc furnace, and the temperature is increased by electric arc in the later stage of smelting, and the tapping temperature at the smelting end is controlled at 1610 ° C ~ 1630 ° C, and the mass percentage of the molten steel composition at the smelting end is: C: 0.08% ~ 0.10%, S , P: ≤0.015%, according to the ratio of molten iron to scrap to determine the amount of oxygen blowing and electricity consumption;

[0020] Step 3: The molten steel at the end point of the electric arc furnace smelting is formed ...

example 1

[0027] Example 1: 30MnSi steel billet 165mm*165mm, mass percentage chemical composition: 0.29%C, 0.92%Si, 1.07%Mn, 0.022%P, 0.020%S, 0.02%Ni, 0.11%Cr, 0.08%Cu.

[0028] Low magnification structure of the billet: grade 0 for central crack, grade 0 for central looseness, grade 0.5 for intermediate crack, grade 0 for corner crack, grade 0 for subcutaneous crack, and grade 0 for non-metallic inclusions.

example 2

[0029] Example 2: 30MnSi steel billet 165mm*165mm, mass percentage chemical composition: 0.30%C, 0.90%Si, 1.17%Mn, 0.018%P, 0.021%S, 0.04%Ni, 0.10%Cr, 0.08%Cu.

[0030] Low magnification structure of the billet: grade 0 for central cracks, grade 0 for central looseness, grade 0 for intermediate cracks, grade 0 for corner cracks, grade 0 for subcutaneous cracks, and grade 0 for non-metallic inclusions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com