Beneficiation machine set

A technology of unit and centrifugal concentrator, which is applied in the direction of centrifuge, solid separation, filter and screen, etc. It can solve the problems of complex and mineral material damage, achieve strong continuity, improve recovery rate, and improve the effect of screening and classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

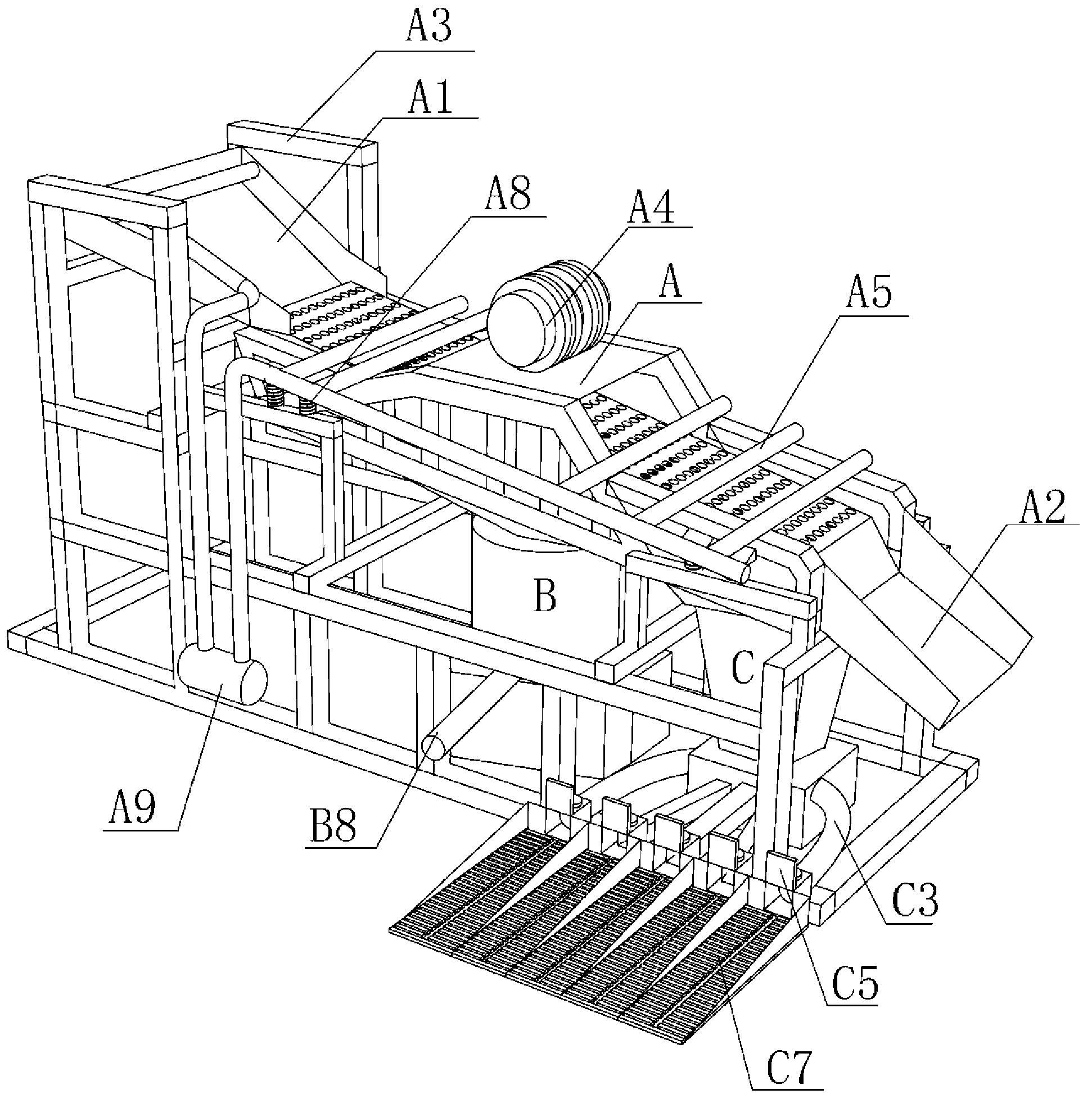

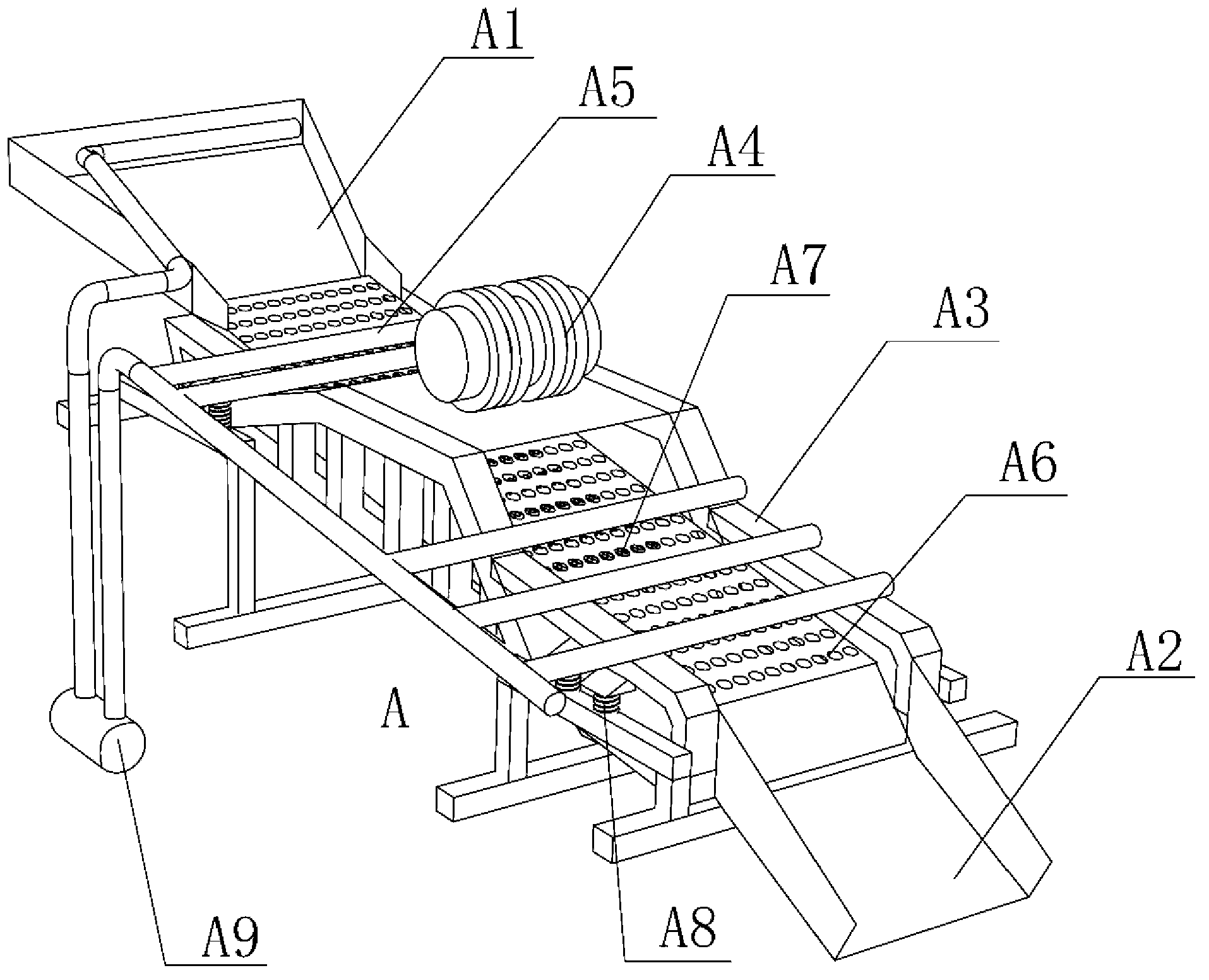

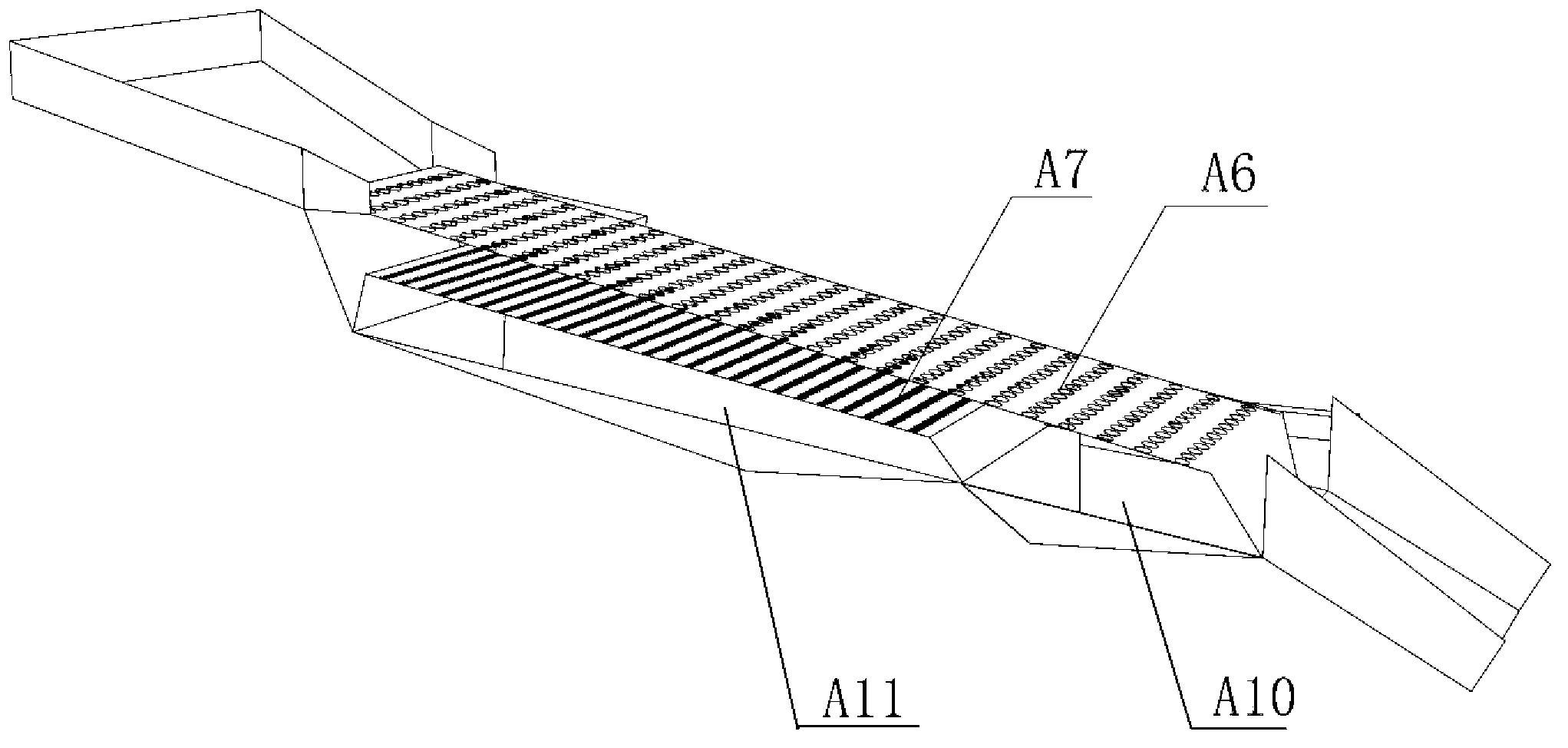

[0035] Such as figure 1 , The mineral processing unit consists of three major components: the vibrating screen A for mineral processing, the centrifugal mineral processing machine B and the coarse-grained ore recovery device C. The vibrating screen A for mineral processing includes the feed inlet A1, the tailing outlet A2 and the frame A3. The feed port A1 and the tailing outlet A2 are arranged at both ends of the frame A3, the oscillator A4 is installed on the top of the frame A3, the vibrating spring A8 is installed at the side of the frame A3, the coarse mineral material screen A6 and the fine The granular mineral material screen A7 is layered up and down in the frame A3, the bottom of the coarse mineral material screen A6 is connected to the coarse mineral material outlet A10, and the bottom of the fine mineral material screen A7 is connected to the fine mineral material outlet A11 , the top of the frame A3 is also provided with a high-pressure water spray pipe A5, and the...

Embodiment 2

[0042] The difference from Example 1 is that the aperture of the coarse mineral material screen 10 is 1 cm, and the aperture size of the fine mineral material screen is 5 mm, and the aperture of the settling hole 11 is 5 mm. The spacing between the grids is 2 cm, there are 6 collecting plates C8, and the settling holes B11 form an angle of 60 degrees with the groove B10. The rest of the working principle is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com