Magnetic fusion heating system

A technology of heating system and heat insulation layer, applied in the direction of induction heating, induction heating device, etc., can solve the problem of waste of electric energy, etc., and achieve the effect of rapid heating and cooling and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing and embodiment:

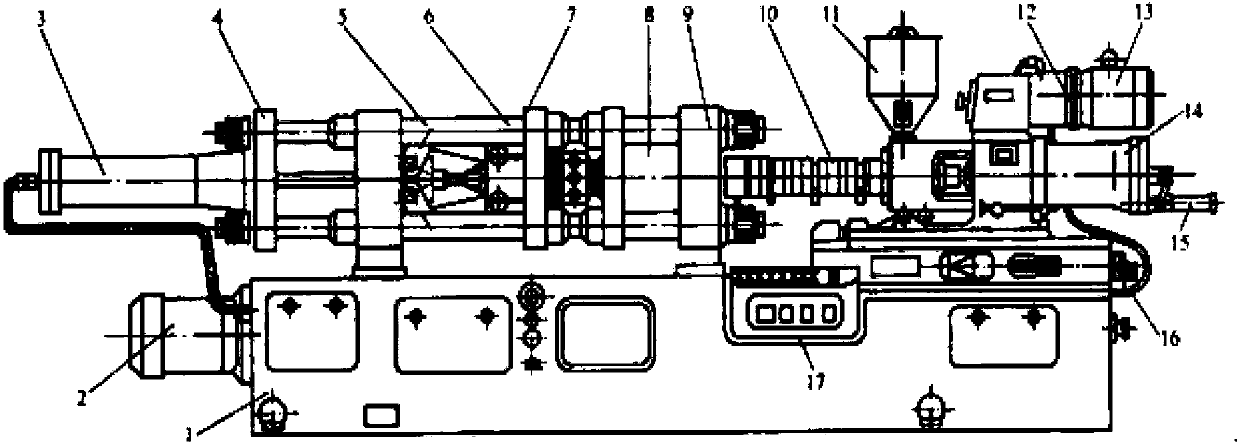

[0017] see figure 1 , which is a schematic diagram of the overall structure of the injection molding machine in the prior art. The horizontal injection molding machine includes a body 1, a hydraulic system motor 2, a clamping cylinder 3, a fixed template 4, a mold clamping mechanism 5, a tie rod 6, a movable template 7, and a forming mold 8 , fixed template 9, barrel, screw and electric heating device 10, hopper 11, screw reduction box 12, drive screw motor 13, injection cylinder 14, metering device 15, injection mobile cylinder 16, console 17. Because the electric heating device is used in the prior art, the outer wall of the steel barrel is wrapped by the resistance wire, and the high temperature is generated by the resistance wire itself, and then the heat is slowly transferred from the high temperature of the outer surface of the steel barrel to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com