Surface protection thin film and optical element bonded with the same

A technology for protecting films and optical components, applied in optical elements, film/sheet-like adhesives, optics, etc., can solve the problems of the corresponding unevenness of the adhesive layer, difficult adhesion, mixed air bubbles, etc., and achieve peeling. Low withstand voltage, improved yield, and stabilized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

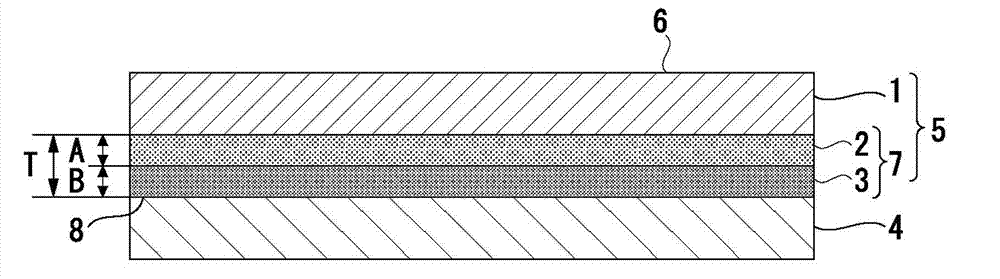

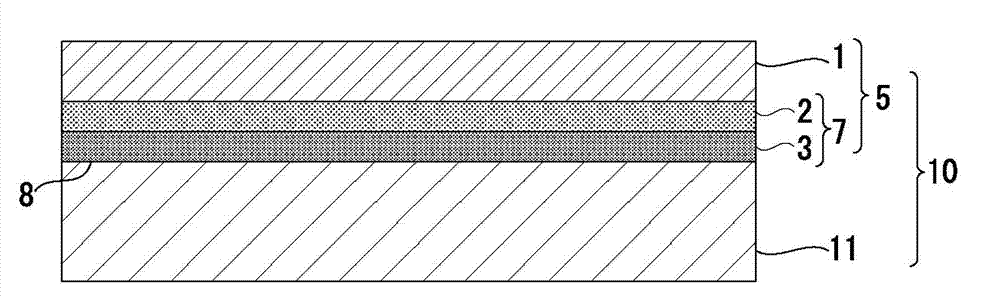

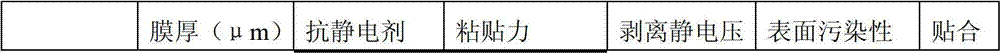

[0069] (The making of the surface protection film of Example 1)

[0070] In order to form a surface resistivity of 1×10 13 For the first adhesive layer above [Ω / □], 3 parts by weight of Adhesive composition (a) was prepared using an isocyanate-based hardener.

[0071] In addition, in order to form a surface resistivity less than 1×10 13 For the second adhesive layer of [Ω / □], bromoalkyltrimethylamine chloride, which is a bromoalkyltrimethylamine salt, is mixed with the adhesive composition (a) as an antistatic agent (manufactured by Kao Corporation, trade name: ELECTROSTRIPA-QN) to prepare an adhesive composition (b). Here, the mixture was mixed at a ratio of 1 part by weight of bromoalkyltrimethylamine chloride with respect to 100 parts by weight of the adhesive composition (a). Here, the adhesive composition (a) was applied to one side of a biaxially stretched polyethylene terephthalate (PET) film having a thickness of 38 μm, and the adhesive composition (a) was applied ...

Embodiment 2

[0073] (The making of the surface protective film of embodiment 2)

[0074] The adhesive composition (a) was laminated on one side of the base film so that the coating thickness of the dried adhesive composition (a) was 17 μm, and the adhesive composition (b) was laminated to make the dried adhesive composition (a) The coating thickness of the adhesive composition (b) was 3 micrometers. Except for this, the surface protection film of Example 2 was obtained in the same manner as in Example 1.

Embodiment 3

[0075] (The making of the surface protective film of embodiment 3)

[0076] Adhesive composition (a) and adhesive composition (b) were laminated on one side of the base film, and the coating thickness of adhesive composition (a) and adhesive composition (b) after drying A total of 10 μm is reached. Except for this, the surface protection film of Example 3 was obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com