Combined guard board for preparing pseudo-single crystal with high utilization rate and method for preparing pseudo-single crystal

A technology of quasi-single crystal and utilization rate, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems affecting the utilization rate of ingot and low yield rate of ingot, and achieve good industrial prospects and low cost. Inexpensive, simple design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

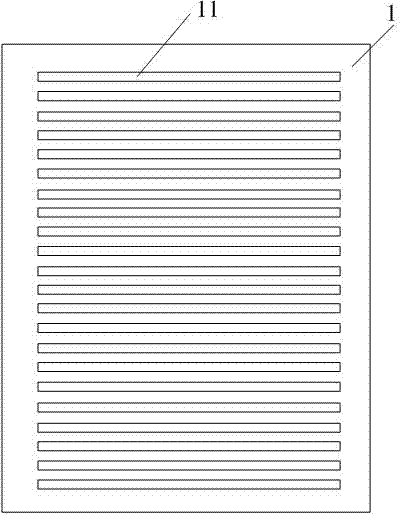

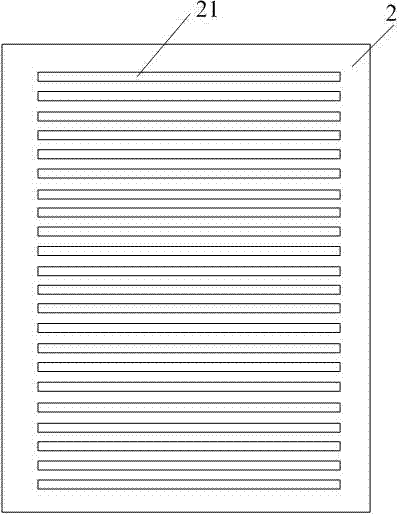

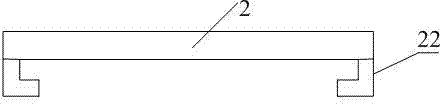

[0032] Such as Figure 1-6 Shown.

[0033] The key technical point to be protected by the present invention is the combined protective plate involved in the present invention. Among the more important aspects of the new combined protective plate involved in the present invention are: 1. The combined protective plate can be made of the same material, It can also be made of two different materials. 2. The combined protective plate is divided into two parts: inside and outside, which can move relative to each other, so that the protective plate is in an open and closed state. 3. There are through holes on the inner and outer guard plates. Under the premise of meeting the strength of the guard plate, the area of the through holes on the inner and outer guard plates can be adjusted.

[0034] Therefore, a high-utility quasi-single crystal combined guard plate is prepared, including the crucible graphite side guard plate 3 attached to the outer wall of the crucible 4, and the crucible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com