Template system and construction method for European style hollowed slab pinnacle model structure

A technology of structural formwork and hollow plate, which is applied in the fields of formwork/template/work frame, building structure, and on-site preparation of building components, etc. Complex problems, to achieve the effect of good seismic effect of the structure, low construction cost, neat and smooth joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

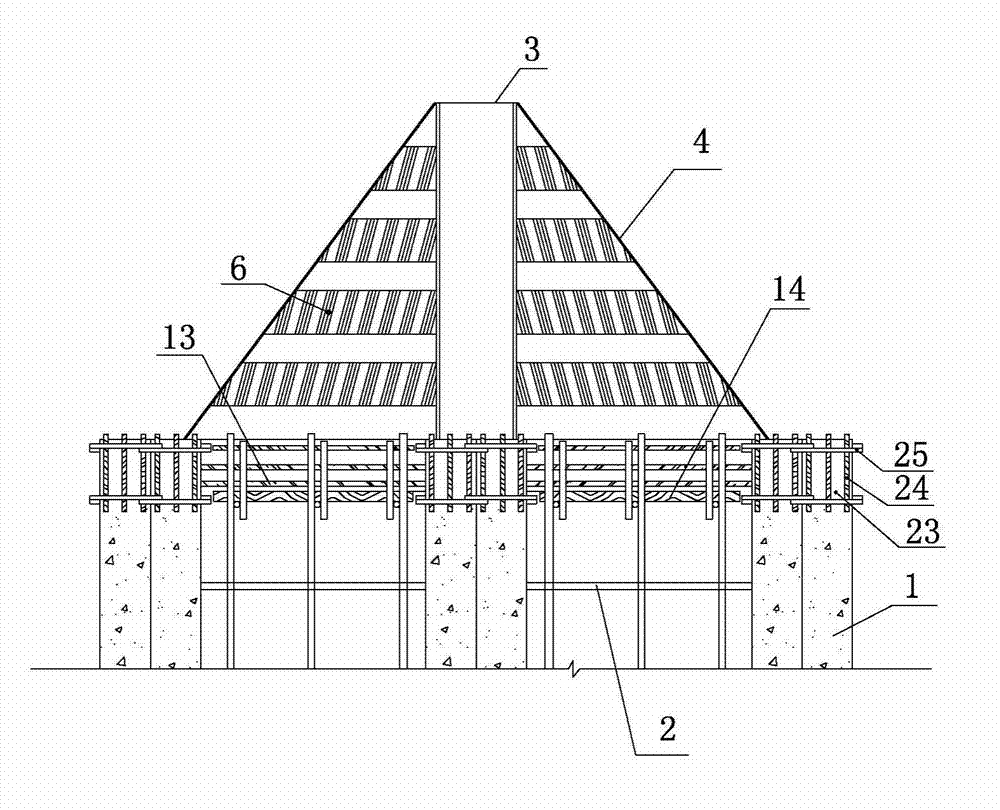

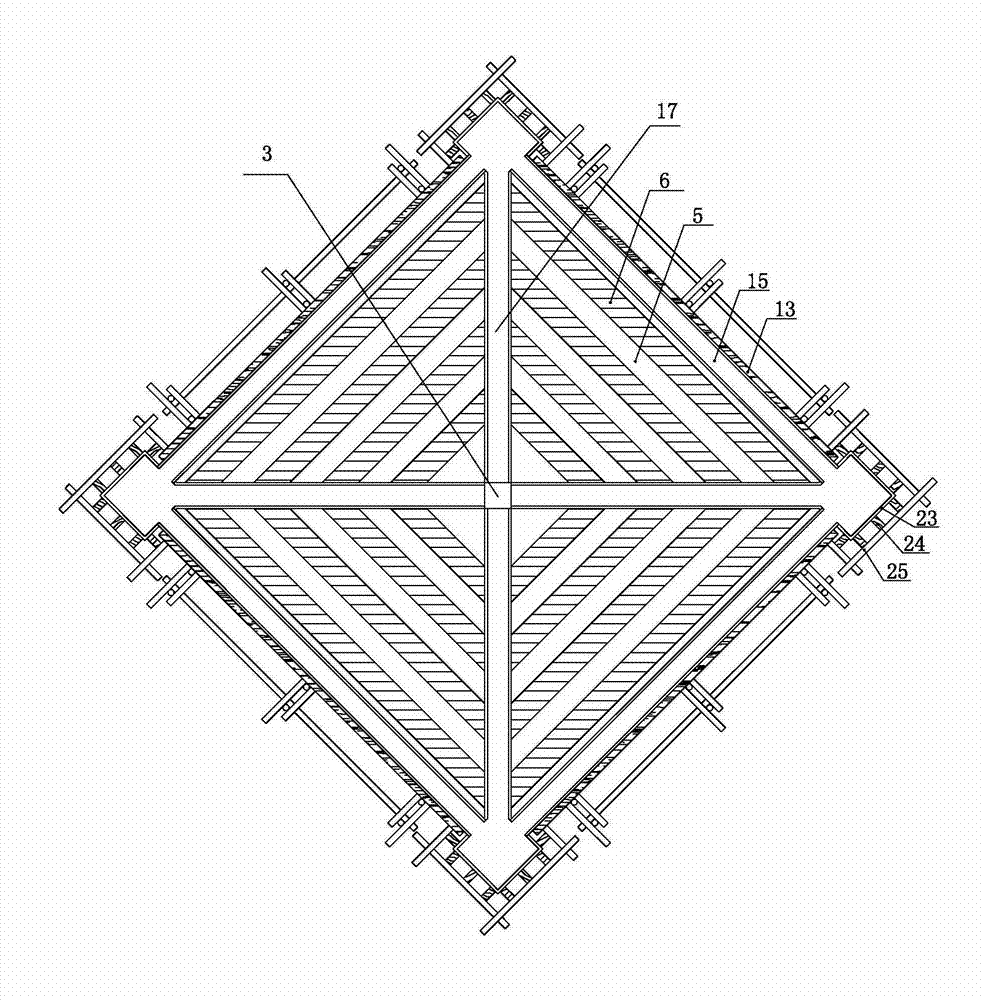

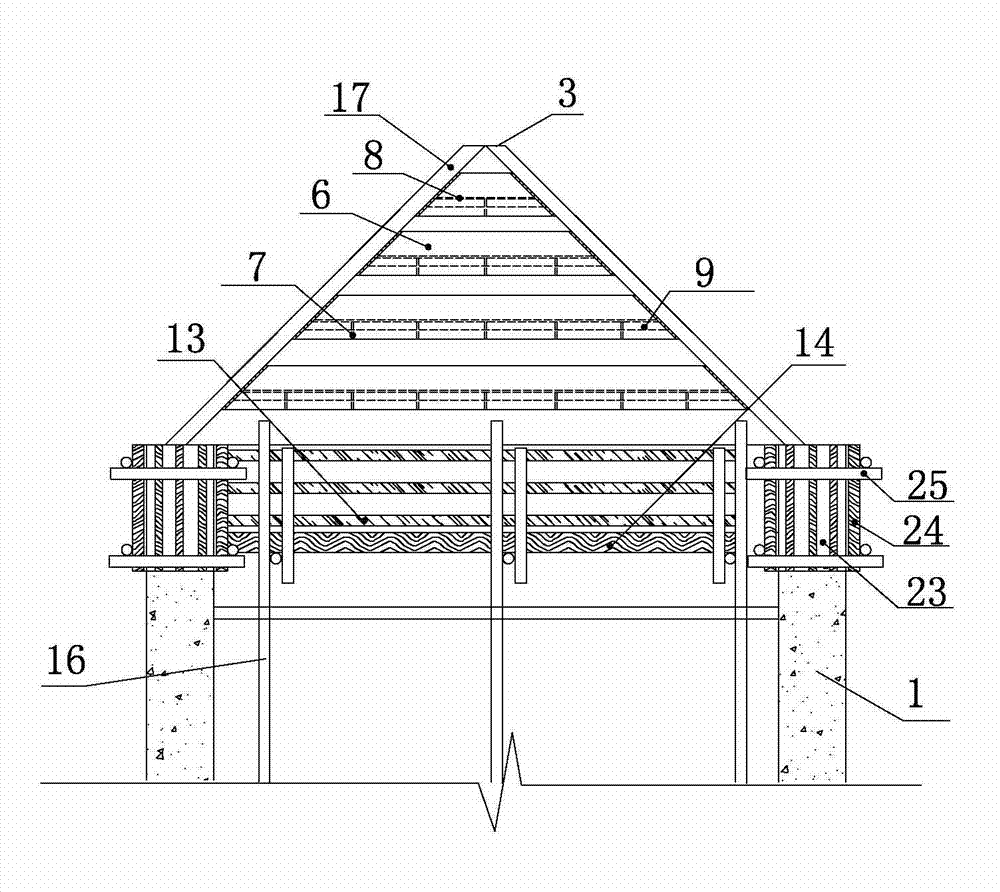

[0030] like figure 1 , image 3 , Figure 9 As shown, the formwork system of the European-style hollowed-out slab peak shape structure of the present invention includes four shaped structural columns 1 that are arranged in a square under the European-style hollowed-out slab peak shape structure and have column cap steel bars exposed on the top surface.

[0031] like Figure 1 ~ Figure 4 As shown, the tops of the four forming structural columns 1 are respectively connected to a column formwork structure 23 through the column head back flute 24 and the column hoop 25 is tightened. A U-shaped side beam formwork structure 15 is horizontally connected between two adjacent column cap formwork structures 23 , and a column cap formwork structure 23 connects two side beam formwork structures 15 at right angles, and at the top of the four column cap formwork structures 23 Between the two side beam formwork structures 15 at right angles to the center of the upper part, an oblique beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com