Reboiling and feeding heating two-in-one heating furnace and fractionation method thereof

A two-in-one heating furnace technology, applied in lighting and heating equipment, furnaces, hydrocarbon distillation, etc., can solve the problems of low investment and land occupation, high vaporization rate at the outlet of the feed heating furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

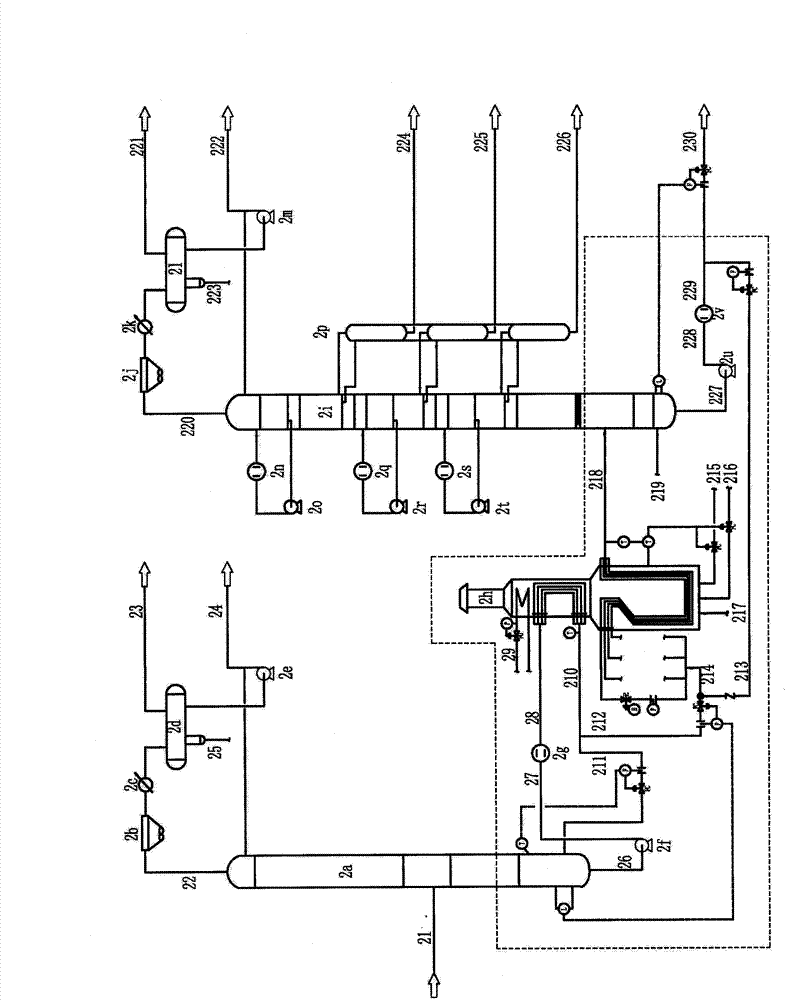

[0061] Such as figure 2 As shown, the heating furnace process technology of the present invention is illustrated by taking the condensate oil processing technology as an example.

[0062] The initial distillation tower feed 1 at about 230°C enters the initial distillation tower 2a, and is divided into initial top oil gas 22 and initial bottom oil 26 after fractionation. The preliminary oil and gas 22 are sequentially condensed and cooled by the primary top air cooler 2b and the primary top aftercooler 2c, and then enter the primary top reflux tank 2d, and are separated into primary top gas 23, primary top oil 24, and primary top sewage 25 through the primary top reflux tank 2d ;

[0063] The first bottom oil 26 is supercharged by the first bottom pump 2f to be the first bottom oil (before the heat exchange) 27, and the logistics 27 becomes the first bottom oil (after the heat exchange) 28 after passing through the first bottom heat exchanger group 2g heat exchange, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com