Method for strengthening activity of limestone-gypsum wet-method flue gas desulfurization slurry

A wet flue gas desulfurization and limestone slurry technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of inability to guarantee the quality of desulfurization by-products, various types of additives, and large application randomness. Solve the effects of increased SO2 concentration, flexible load adjustment, and simple technical transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

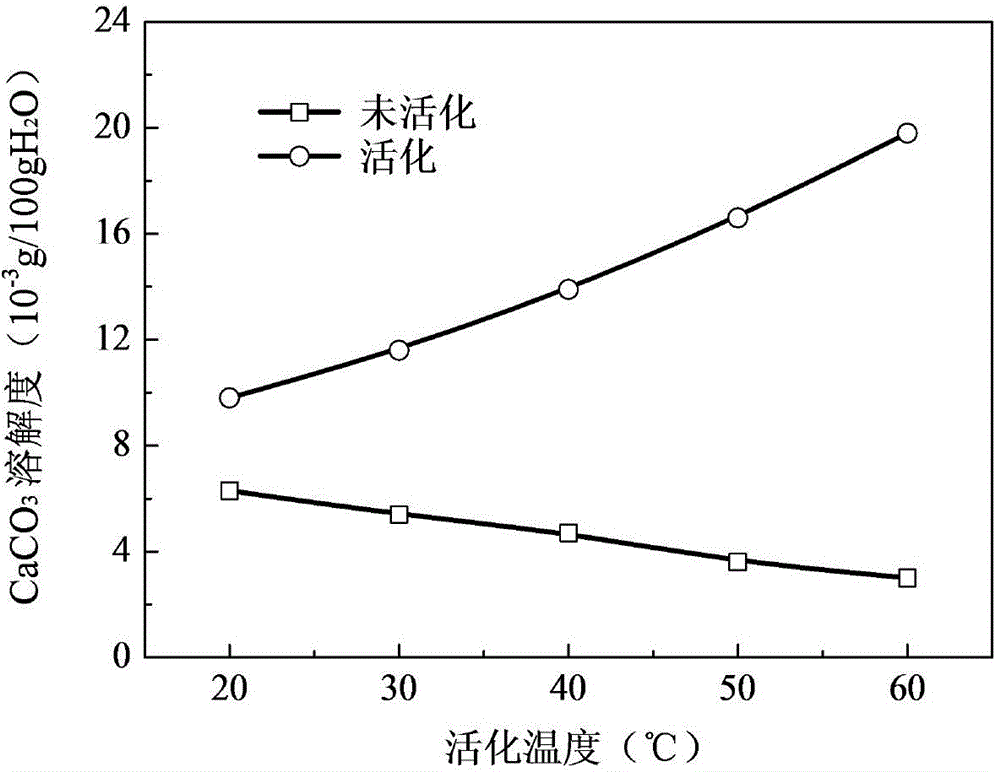

[0031] Using a glass kettle reactor (inner diameter 100 mm, height 200 mm), firstly carry out the limestone slurry activation test, that is, add 300 mL of distilled water and 10 g of analytically pure CaCO3 solid powder into the reactor, and then continuously feed 30 mL of CO2 gas into the reactor and stir 3 hours, made CaCO3 solution. The temperature of the reactor is controlled by a horizontal temperature water bath, and the activation temperature is 20-60°C; the pH value is monitored in real time by a Starter300 portable pH meter; CO2 gas is provided by cylinder gas, and the flow rate is controlled by a mass flow meter. After the activation is completed, take out the CaCO3 slurry sample, filter the CaCO3 solute that may be brought out through the filter paper and the funnel, and make a saturated aqueous solution; then weigh it with a ten-thousandth electronic balance, and use the liquid evaporation method to obtain the solute CaCO3, after calculation Get the solubility of C...

Embodiment 2

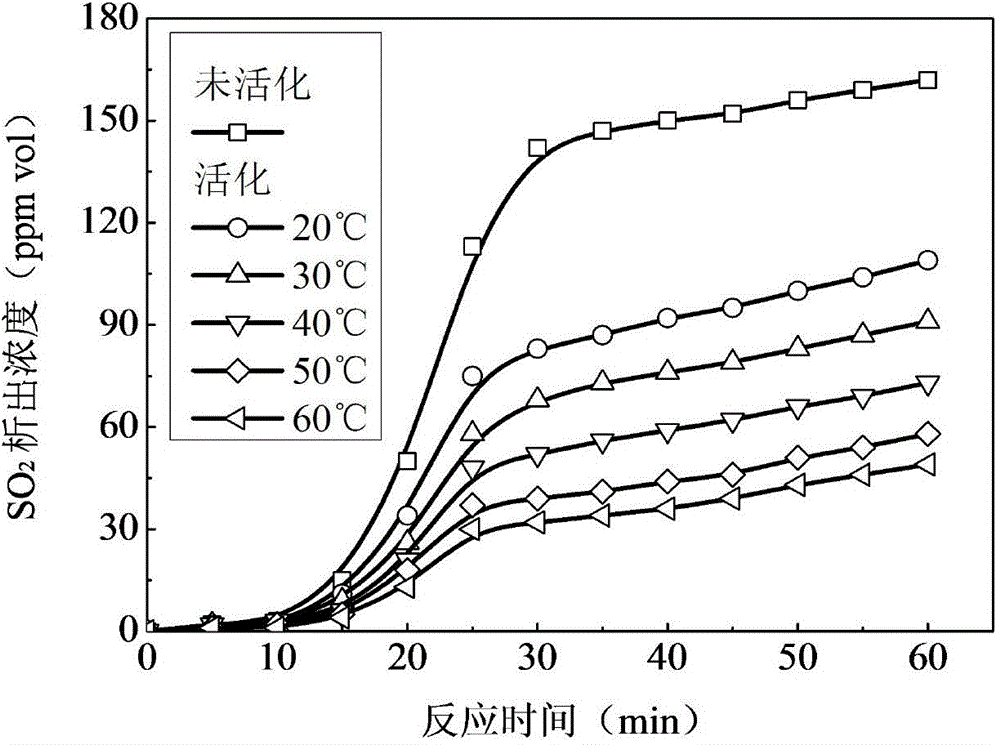

[0034] The continuous reaction test of limestone-gypsum wet flue gas desulfurization was carried out on the laboratory desulfurization system. The absorption tower is a circular reactor made of plexiglass, with a height of 1.5m and an outer diameter of 0.05m. During the test, cylinder gas (O2, CO2 and SO2) was used as the gas source, the total flow rate was 2m3 / h, the flue gas composition was O2: 0.4m3 / h, CO2: 1.6m3 / h, and the volume concentration of SO2 was about 1000ppm. The simulated flue gas is firstly mixed evenly by the gas mixer and the preheater and heated to 120°C, and then flows through the absorption tower from the bottom up through the flue gas inlet; and the limestone slurry with a concentration of 5% is composed of limestone with a particle size of 20-63 μm It is sprayed from the top nozzle by the pump, and absorbs SO2 gas in countercurrent contact with the flue gas. The flow rate of the water pump is stabilized to 150L / h by adjusting the valve, and the slurry t...

Embodiment 3

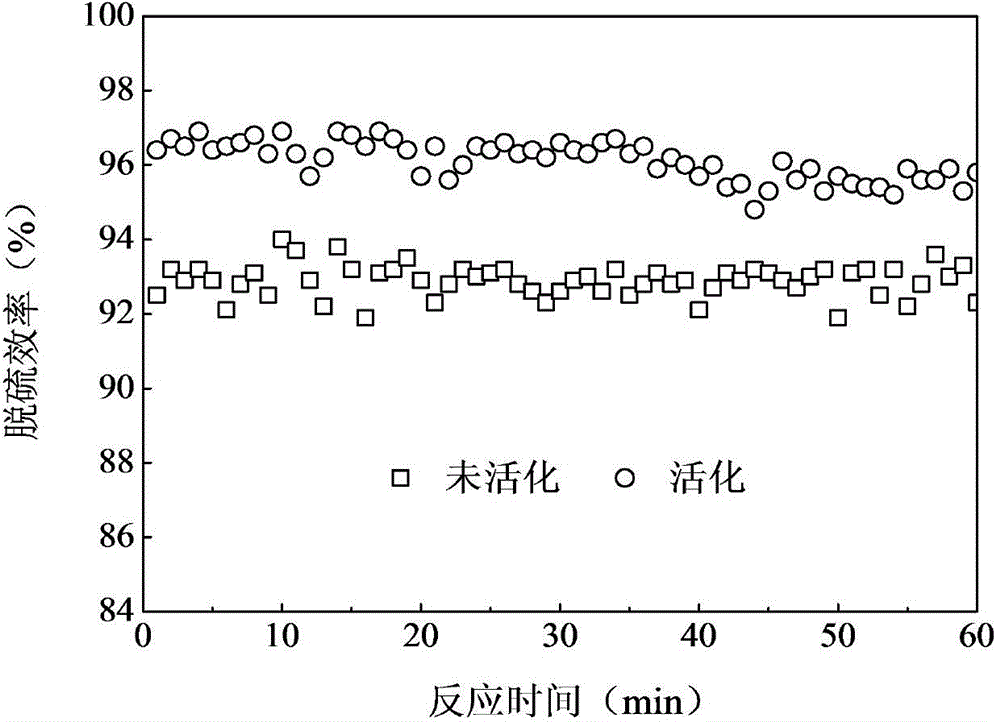

[0036] The 2×350WM unit of a power plant adopts the limestone-gypsum wet-process full flue gas desulfurization process, one furnace and one tower desulfurization device, and a common set of desulfurization absorption preparation and gypsum slurry dehydration systems. The sulfur content of the designed coal is 0.6-1.2%. The limestone wet ball mill pulping system is used in the desulfurization process. The particle size of limestone is ≤63μm (90% passes through 250 mesh). 1160kg / m3, the pH value of the slurry is between 5.2 and 5.6, and the Ca / S ratio is 1.03. The SO2 concentration in the inlet flue gas is 1800-2000mg / m3, and the SO2 concentration in the outlet flue gas is 80-90mg / m3. When the desulfurization system is running, the three slurry circulation pumps operate for a long time, the liquid-gas ratio is about 14.8L / m3, and the desulfurization efficiency is about 95.2-95.7%. The gas ratio drops to 9.8L / m3, and the desulfurization efficiency drops to 90.3-90.8%.

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com