Automatic force adjustment device for micro-Vickers hardness meter

A technology of Vickers hardness tester and adjustment device, applied in the direction of testing material hardness, etc., can solve the problems of weight rod impact, uneven rotation speed, dislocation of weight rod, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

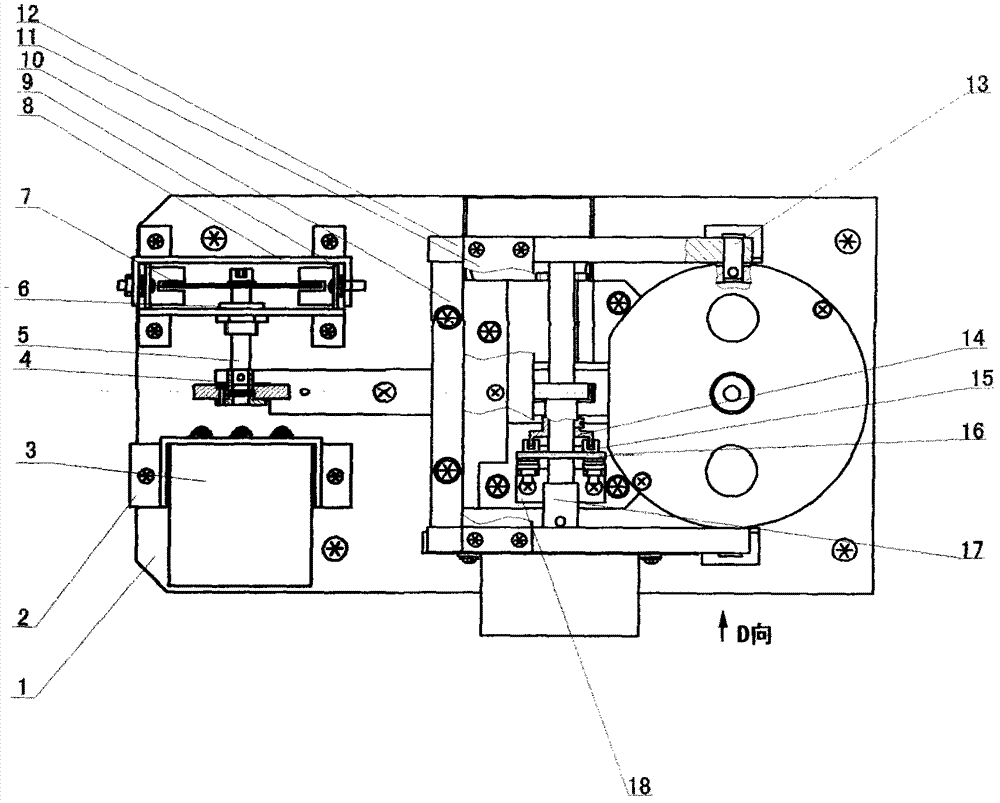

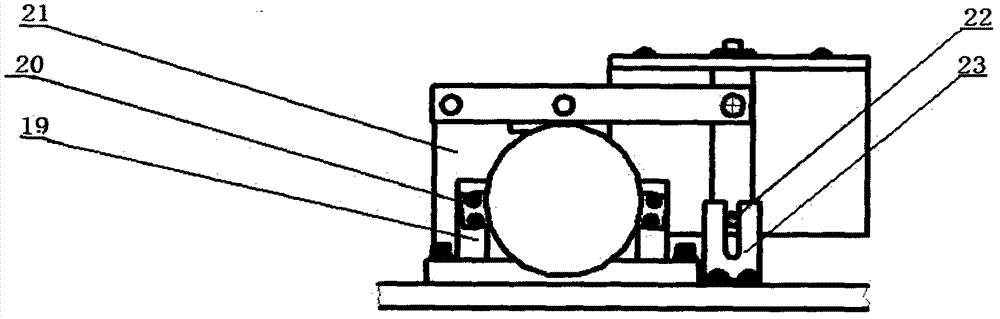

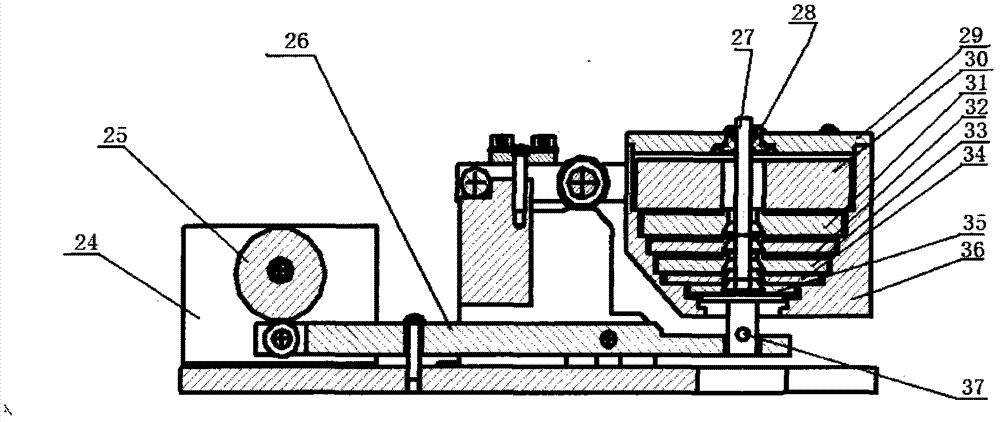

[0012] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in detail, by figure 1 , figure 2 and image 3 As shown in the structural diagram of the automatic force value adjustment device of the micro-Vickers hardness tester of the present invention, the bottom plate 1 is fixed on the micro-Vickers hardness tester by screws, and the motor support 2 is fixed on the bottom plate 1. The motor support 2 The permanent magnet capacity-splitting synchronous motor 3 is fixed by screws, the permanent magnet capacity-separation synchronous motor 3 provides power for the loading and unloading cam 25, the loading and unloading cam 25 is in movable contact with the lever 26, and the loading and unloading cam 21 is fixed on the electronic coupling by screws 4, the electronic coupling 4 is connected to the motor shaft of the permanent magnet capacitive synchronous motor 3 through pins, wherein the disc shaft 5 is fixed on the electroni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com