Soft start control system for high-speed brushless DC motor

A technology for DC motors and control systems, applied in the direction of DC circuits that can reduce harmonics/ripples, starting devices, etc., can solve problems such as high harmonic content, large starting current, etc., to improve operating efficiency and life, reduce The effect of starting current and reducing the eddy current loss of the rotor body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

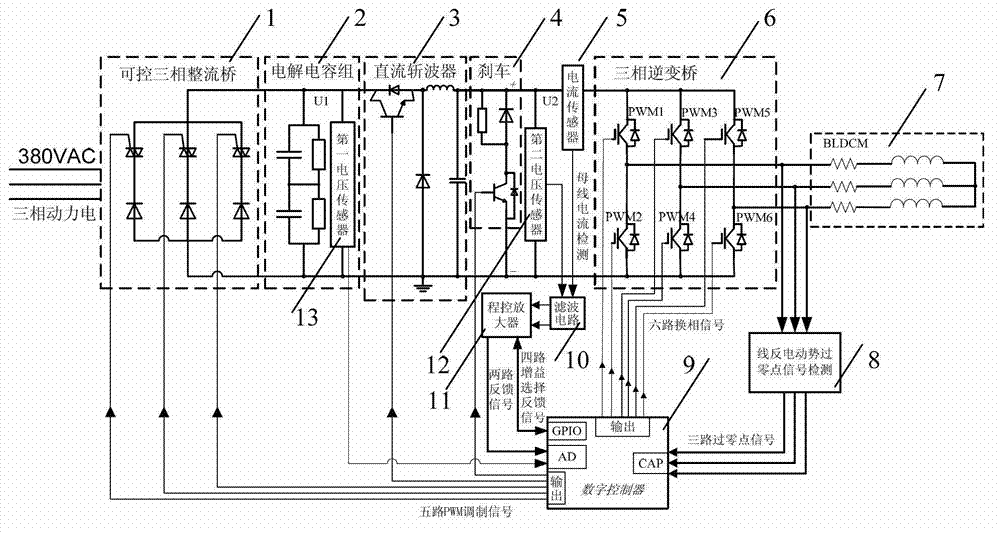

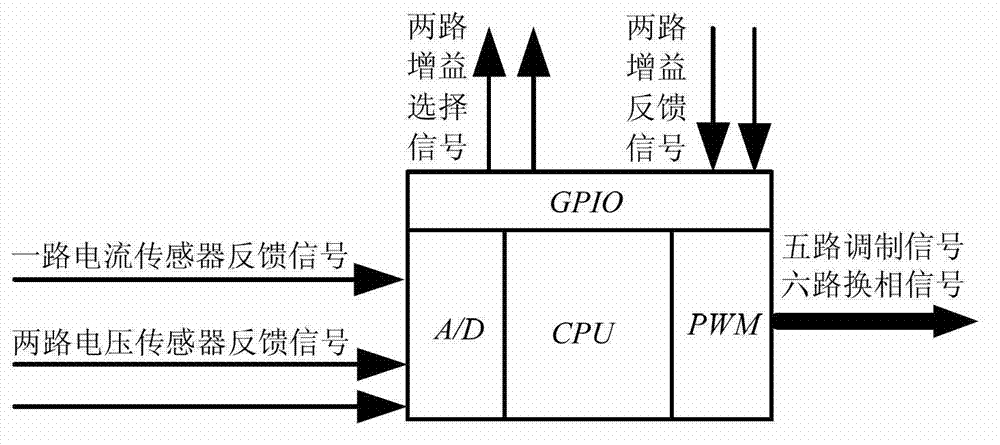

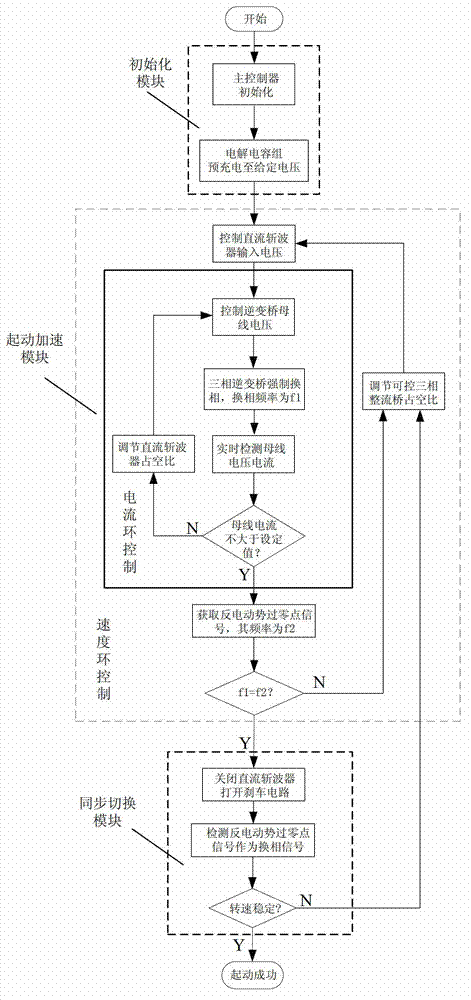

[0019] Such as figure 1Shown is a high-speed brushless DC motor soft start control system, including a controllable three-phase rectifier bridge 1, an electrolytic capacitor bank 2, a DC chopper 3, a brake circuit 4, a current sensor 5, a three-phase inverter bridge 6, Brushless DC motor 7 , line counter electromotive force zero-crossing signal detection circuit 8 , digital controller 9 , filter circuit 10 , program-controlled amplifier 11 , second voltage sensor 12 , and first voltage sensor 13 . The three-phase power supply outputs DC voltage U1 after passing through the controllable three-phase rectifier bridge 1. U1 is connected in parallel with electrolytic capacitor group 2 for filtering. The input voltage of the device 3, after passing through the DC chopper, outputs a controllable DC voltage U2 with a lower amplitude. The two ends of U2 are connected in parallel with the second voltage sensor 12 for voltage detection, and the current sensor 5 is connected in series wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com