High power high voltage generator

A high-voltage generator, high-power technology, applied in X-ray equipment, electrical components, etc., can solve the problems of difficult 1ms exposure function, slow open-loop response speed, low operating frequency, etc. Heat dissipation method, the effect of less heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

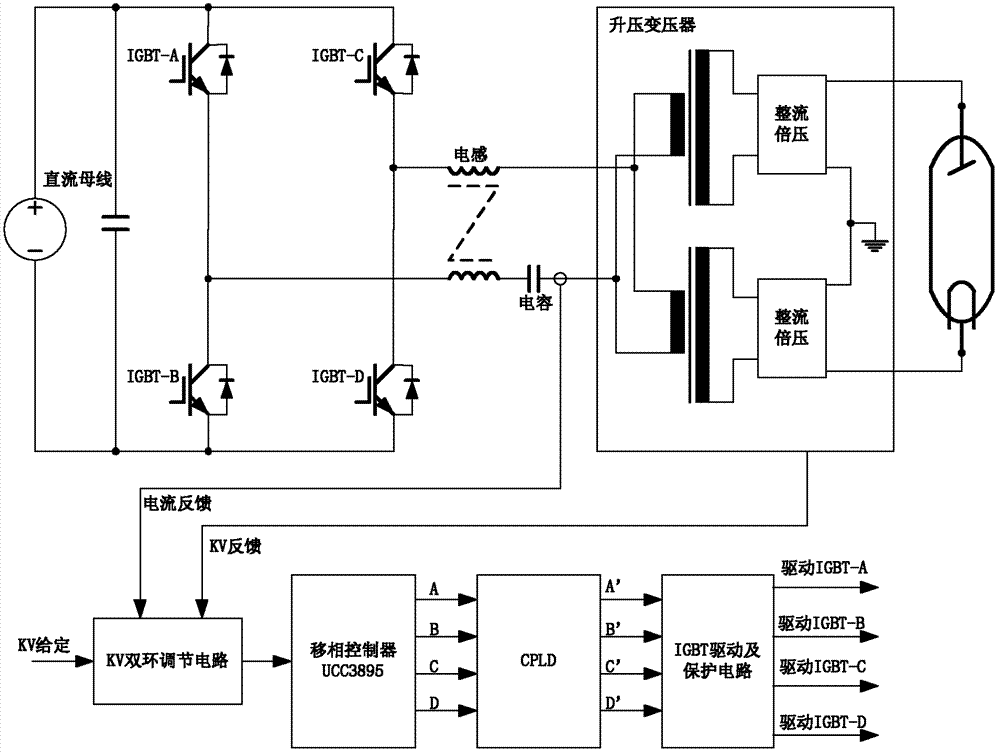

[0024] Such as figure 1 As shown, the high-power high-voltage generator of the present invention includes: a main loop and a control part, wherein the main loop uses IGBT (Insulated Gate Bipolar Transistor) Bipolar transistor) As The inverter module forms a full-bridge inverter circuit. The output terminal of the full-bridge inverter circuit is connected to the resonance circuit and the step-up transformer to output high voltage; the control part includes KV double-loop regulating circuit, phase shift controller, CPLD (Complex Programmable Logic Device) Programming logic device) and IGBT drive and protection circuit. The input terminal of the KV double-loop regulating circuit receives the KV given value, the current feedback signal and voltage feedback signal of the main loop, and the output terminal is connected to the CPLD through the phase shift controller, and the output of the CPLD The signal is sent to the gate of each IGBT in the main loop through the IGBT drive and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com