Novel super abrasion-resisting rubber sole and preparation method thereof

A rubber sole and anti-abrasion technology, applied in the field of rubber materials, can solve problems such as poor anti-abrasion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

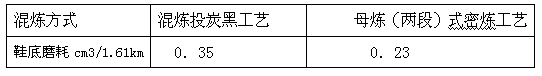

Method used

Image

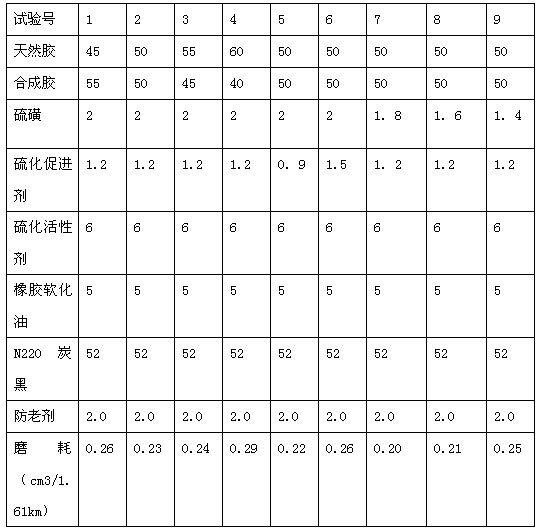

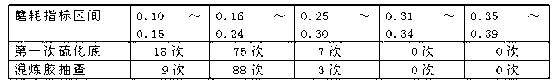

Examples

Embodiment 1

[0097] Embodiment 1 of the present invention: novel super wear-resistant type rubber sole, calculated according to parts by weight, it comprises 50 parts of natural rubber, 50 parts of synthetic rubber, 1.8 parts of sulfur, 1.2 parts of vulcanization accelerator, 8 parts of vulcanization active agent, rubber softening 7 parts of oil, 50 parts of N220 carbon black and 2.5 parts of antioxidant; every 1.2 parts of vulcanization accelerator is composed of 0.3 parts of accelerator DM and 0.9 parts of accelerator CBS; every 8 parts of vulcanization accelerator is composed of 4.5 parts of active zinc oxide and 3.5 parts of 2.5 parts of antiaging agent is composed of 1.1 parts of antiaging agent CD and 1.4 parts of antiaging agent 4010NA.

[0098] The preparation method of novel super wear-resistant type rubber sole comprises the steps:

[0099] Step 1. Pre-mixing: Add N220 carbon black, synthetic rubber, natural rubber, vulcanization activator and rubber softening oil to the internal...

Embodiment 2

[0103] Embodiment 2 of the present invention: novel super wear-resistant type rubber sole, calculated according to parts by weight, it comprises natural rubber 55 parts, synthetic rubber 45 parts, sulfur 1.6 part, vulcanization accelerator 0.9 part, vulcanization active agent 9 parts, rubber softening 5 parts of oil, 48 parts of N220 carbon black and 2.3 parts of anti-aging agent; every 1.2 parts of vulcanization accelerator is composed of 0.3 parts of accelerator DM and 0.9 parts of accelerator CBS; every 8 parts of vulcanization accelerator is composed of 4.5 parts of active zinc oxide and 3.5 parts of 2.5 parts of antiaging agent is composed of 1.1 parts of antiaging agent CD and 1.4 parts of antiaging agent 4010NA.

[0104] The preparation method is the same as in Example 1.

Embodiment 3

[0105] Embodiment 3 of the present invention: novel super wear-resistant type rubber sole, calculates by weight, it comprises 53 parts of natural rubbers, 47 parts of synthetic rubbers, 1.7 parts of sulfur, 1.5 parts of vulcanization accelerators, 9 parts of vulcanization activators, rubber softening 8 parts of oil, 52 parts of N220 carbon black and 2.7 parts of antioxidant; every 1.2 parts of vulcanization accelerator is composed of 0.3 parts of accelerator DM and 0.9 parts of accelerator CBS; every 8 parts of vulcanization accelerator is composed of 4.5 parts of active zinc oxide and 3.5 parts of 2.5 parts of antiaging agent is composed of 1.1 parts of antiaging agent CD and 1.4 parts of antiaging agent 4010NA.

[0106] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com