Water-soluble paint, preparation method and spraying technique thereof

A technology for water-soluble coatings and raw materials, applied in the fields of water-soluble coatings, spraying processes, and preparation, can solve the problems of increased production costs, inconsistent with the development trend of green environmental protection science, and inability to implement wet-on-wet construction processes, and achieve film-forming adhesion. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

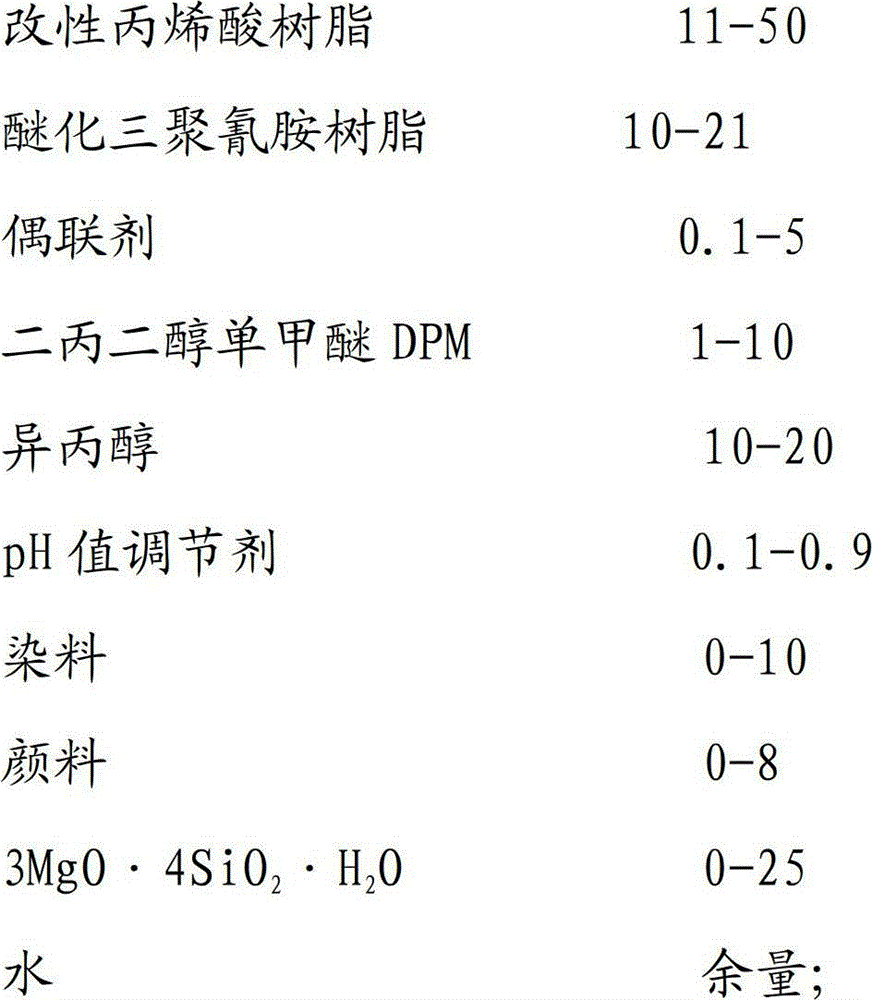

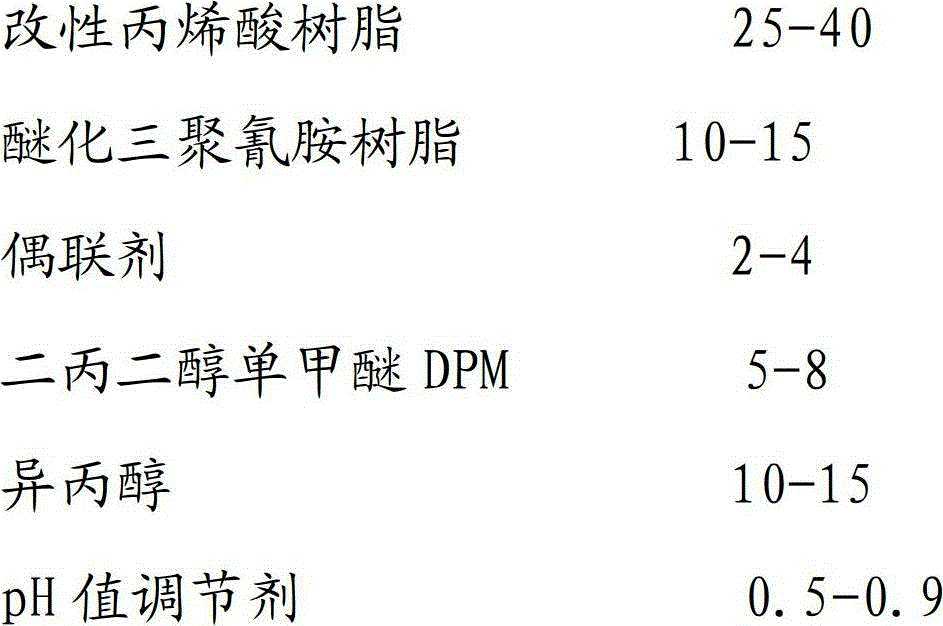

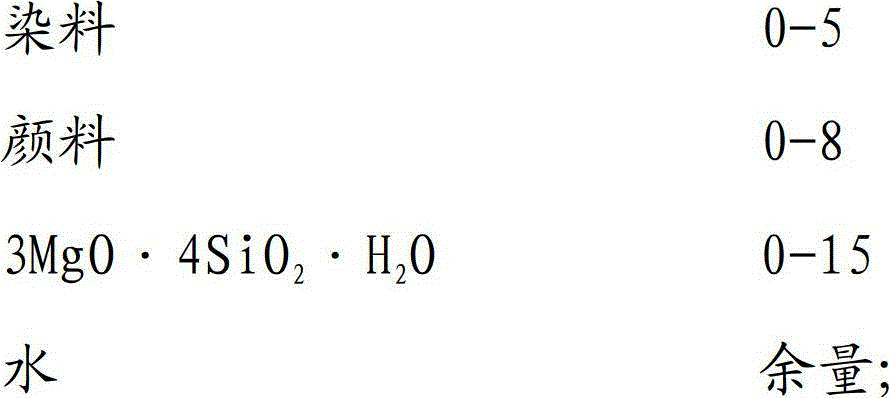

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the water-soluble coating described in the present embodiment, comprises the steps:

[0044] (1) Weigh dipropylene glycol monomethyl ether DPM and isopropanol in proportion, then add modified acrylic resin, etherified melamine resin and coupling agent, and stir for 3-10 minutes;

[0045] (2) Mix the pH regulator with water and add it to the mixed solution obtained in step (1), adjust the pH value to 8.5-9.5, and stir for 5-10 minutes to obtain a transparent water-soluble paint;

[0046] (3) Adding dyes to the transparent water-soluble paint obtained in step (2) to obtain the water-soluble paint.

[0047] The spraying process of the water-soluble paint prepared by the above method on the bottom surface of glass, ceramics, hardware and electroplated products: multi-layer spraying on the workpiece to be sprayed or low-temperature preheating after each layer of spraying, and then baking at 160 ° C Serve in 15 minutes.

[0048] Embodiment 1 perfor...

Embodiment 2

[0054] The preparation method of water-soluble coating described in the present embodiment, comprises the steps:

[0055](1) Weigh dipropylene glycol monomethyl ether DPM and isopropanol in proportion, then add modified acrylic resin, etherified melamine resin and coupling agent, and stir for 3-10 minutes;

[0056] (2) Mix the pH regulator with water and add it to the mixed solution obtained in step (1), adjust the pH value to 8.5-9.5, and stir for 5-10 minutes to obtain a transparent water-soluble paint;

[0057] (3) The pigment and 3MgO·4SiO 2 ·H 2 O is added to the transparent water-soluble paint obtained in step (2) to obtain the water-soluble paint.

[0058] The spraying process of the water-soluble paint prepared by the above method on the bottom surface of glass, ceramics, hardware and its electroplated products: multi-layer spraying on the workpiece to be sprayed or low-temperature preheating after each layer of spraying, and then baking at 110 ° C Serve in 20 minut...

Embodiment 3

[0063] The preparation method of water-soluble coating described in the present embodiment, comprises the steps:

[0064] (1) Weigh dipropylene glycol monomethyl ether and isopropanol in proportion, then add modified acrylic resin, etherified melamine resin and coupling agent, and stir for 3-10 minutes;

[0065] (2) Mix the pH regulator with water and add it to the mixed solution obtained in step (1), adjust the pH value to 8.5-9.5, and stir for 5-10 minutes to obtain a transparent water-soluble paint;

[0066] (3) Combine dyes, pigments and 3MgO·4SiO 2 ·H 2 O is added to the transparent water-soluble paint obtained in step (2) to obtain the water-soluble paint.

[0067] The spraying process of the water-soluble paint prepared by the above method on the bottom surface of glass, ceramics, hardware and its electroplating products: multi-layer spraying on the workpiece to be sprayed or low-temperature preheating after each layer of spraying, and then baking at 120 ° C Serve in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com