Water soluble paint and producing technique thereof

A water-soluble paint, hydrolysis polycondensation technology, applied in the direction of coating, latex paint, etc., can solve the problems of poor paint leveling effect, fried spots, affecting the application of water-soluble paint, etc., to solve the compatibility and water-solubility problems , film adhesion performance improvement, good paint film adhesion effect

Active Publication Date: 2010-09-08

深圳市莱莉雅环保科技有限公司

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the baking film-forming temperature of water-soluble coatings on the market is generally around 180 degrees. The higher temperature requirements have caused an increase in production costs, and some coatings, such as some plastics, metal aluminum, zinc, and some Some alloys are prone to deformation and aliasing at such a high temperature, which affects the application of water-soluble coatings; at the same time, due to the high content of defoamers in some water-soluble coatings on the market, it is easy to cause defoaming when breaking the foam. Shrinkage cavities or fried spots are formed on the surface of the paint film, which makes the leveling effect of the paint poor

In addition, some water-soluble coatings also have problems of poor adhesion, anti-aging, and poor anti-ultraviolet effects, which cause the coated paint film to fall off, lose color or bleed after a period of time, etc.

Since water-soluble paints use water as the basic solvent, even if various surfactants and emulsifiers are added to the paint formula to improve the compatibility and water solubility of the components, the traditional preparation process is still difficult to achieve Blends all ingredients synergistically without compromising their potency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

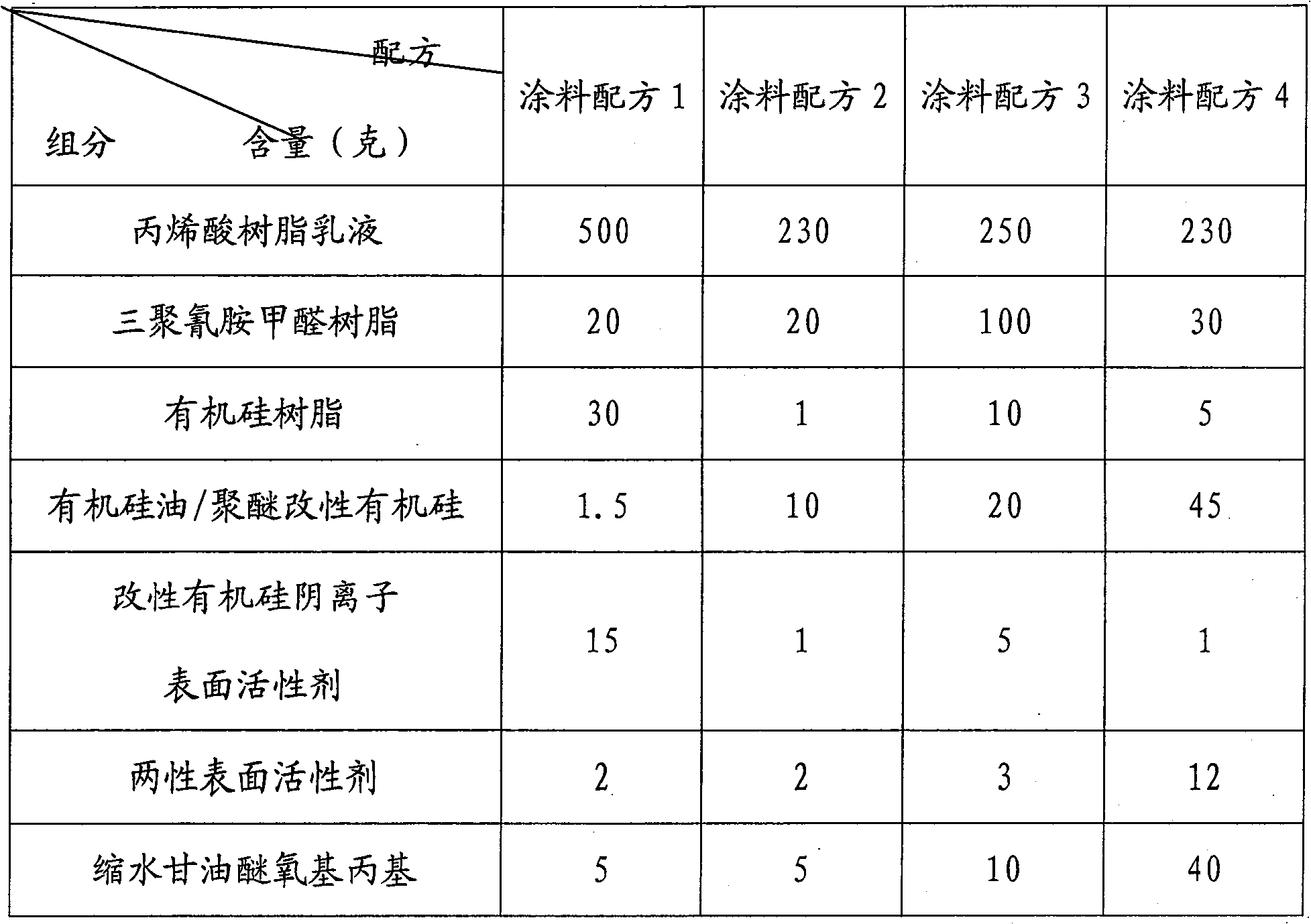

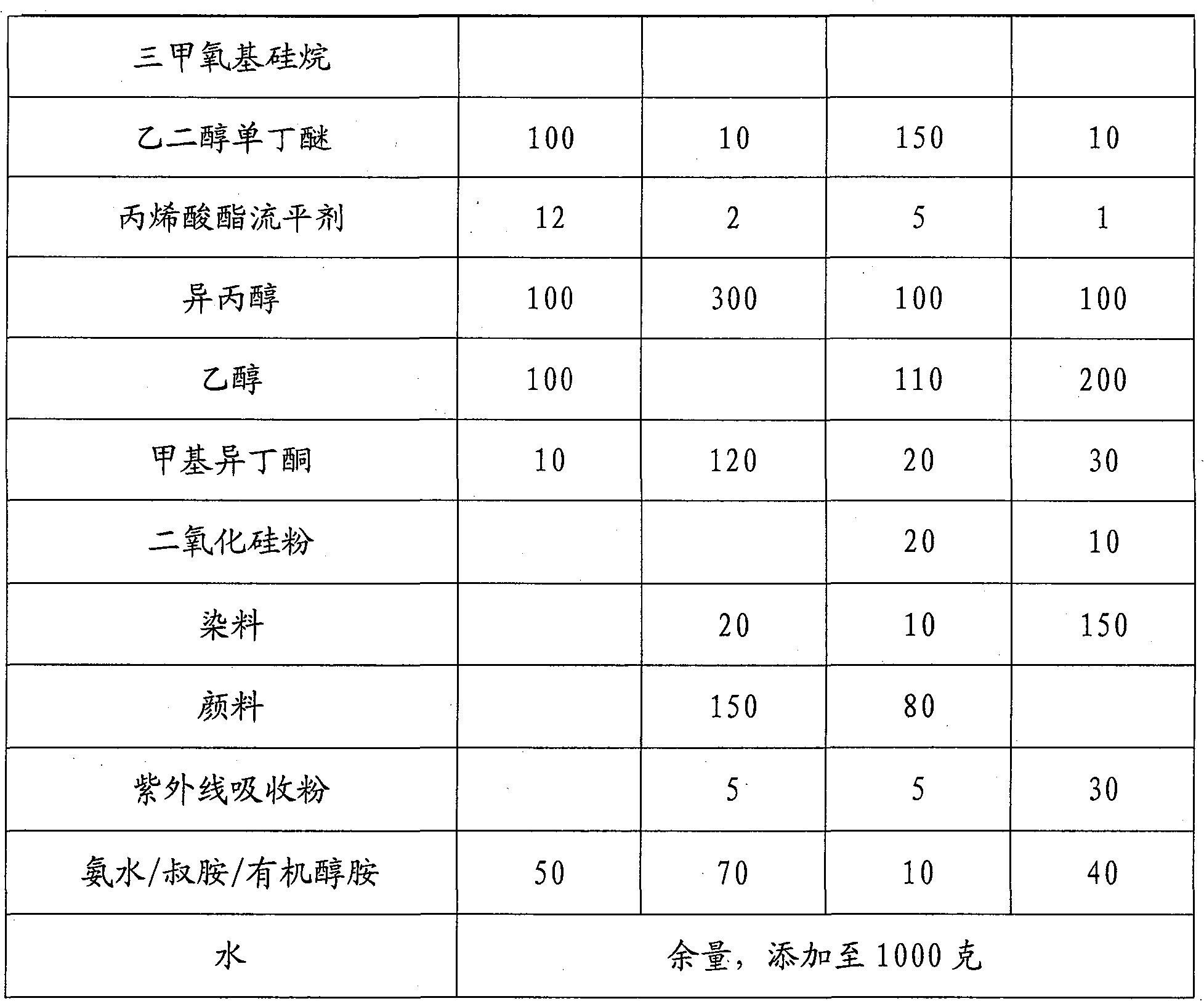

The invention relates to a water soluble coating, whose components comprise acrylic resin emulsion 23 to 50, curing agent 2 to 10, organic silicon resin 0.1 to 3, defoaming agent 0.15 to 4.5, surfactant 0.3 to 2.7, coupling agent 0.5 to 4, emulsifier 1 to 15, leveling agent 0.1 to 1.2, cosolvent 21 to 62, pH regulator 1 to 7 and a reminder of water in total percentage. On the basis of the characteristics of safe, environment protecting and convenient in construction of the normal water soluble coating being kept, the temperature of film forming by curing is decreased, and the adhesion, anti-aging and anti-ultraviolet ability are increased. The invention also provides a production process of the water soluble coating.

Description

technical field The present invention relates to a paint, more specifically to a water-soluble paint and a production process thereof. Background technique Traditional oil-based paints are often flammable and explosive, and there are great safety hazards in production, transportation, storage and use, and most of the oil-based paints contain toxic solvents such as benzene, which are more harmful to the human body and bring serious harm. Environmental issues. In recent years, water-based coatings have become more and more popular in the market because they do not contain benzene solvents and are not flammable and explosive, which bring environmental protection and safety. Compared with oil-based paints, water-based paints are better in acid resistance, water resistance, salt spray resistance, etc., and the paint is easy to construct, no matter spraying, dipping or machine dyeing, there are no disadvantages, and the applied coating has strong adhesion and is not easy to paint...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D133/02C09D5/02C09D183/00

Inventor 李传才

Owner 深圳市莱莉雅环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com