Container type liquid flow stirring device

A stirring device and liquid flow technology, applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical instruments, etc., can solve the problems of high operating cost and poor stirring effect, and achieve low operating cost, good stirring effect, Avoid the effect of liquid surface floating mass crusting and sediment agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

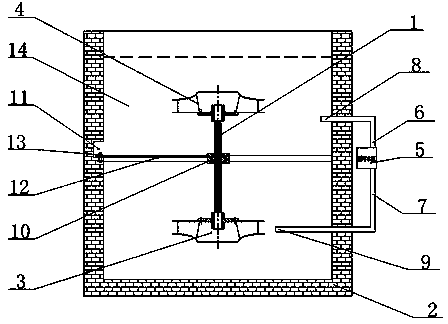

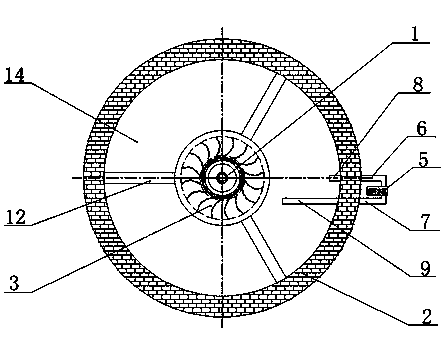

[0024] The utility model will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] see figure 1 , a container-type liquid flow stirring device, including a main shaft 1, the main shaft 1 is located inside the pool wall 2, the biogas slurry 14 is installed in the pool wall 2, and the lower stirring impeller 3 is fixed on the lower end of the main shaft 1, and the The upper end of the main shaft 1 is fixed with an upper stirring impeller 4, and the outside of the pool wall 2 is provided with a circulating water pump 5, the inlet of the circulating water pump 5 is connected with the suction pipe 6, and the outlet of the circulating water pump 5 is connected with the water outlet pipe 7. The water outlet 8 of the suction pipe 6 and the water outlet 9 of the water outlet pipe 7 are all located inside the pool wall 2, and the upper stirring impeller 4 and the water outlet 8 are all located below the biogas slurry 14, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com