Gantry type large-width pattern sewing machine

A pattern machine and gantry-type technology, applied in the field of sewing machines, to achieve the effects of reducing labor intensity, avoiding poor rigidity, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

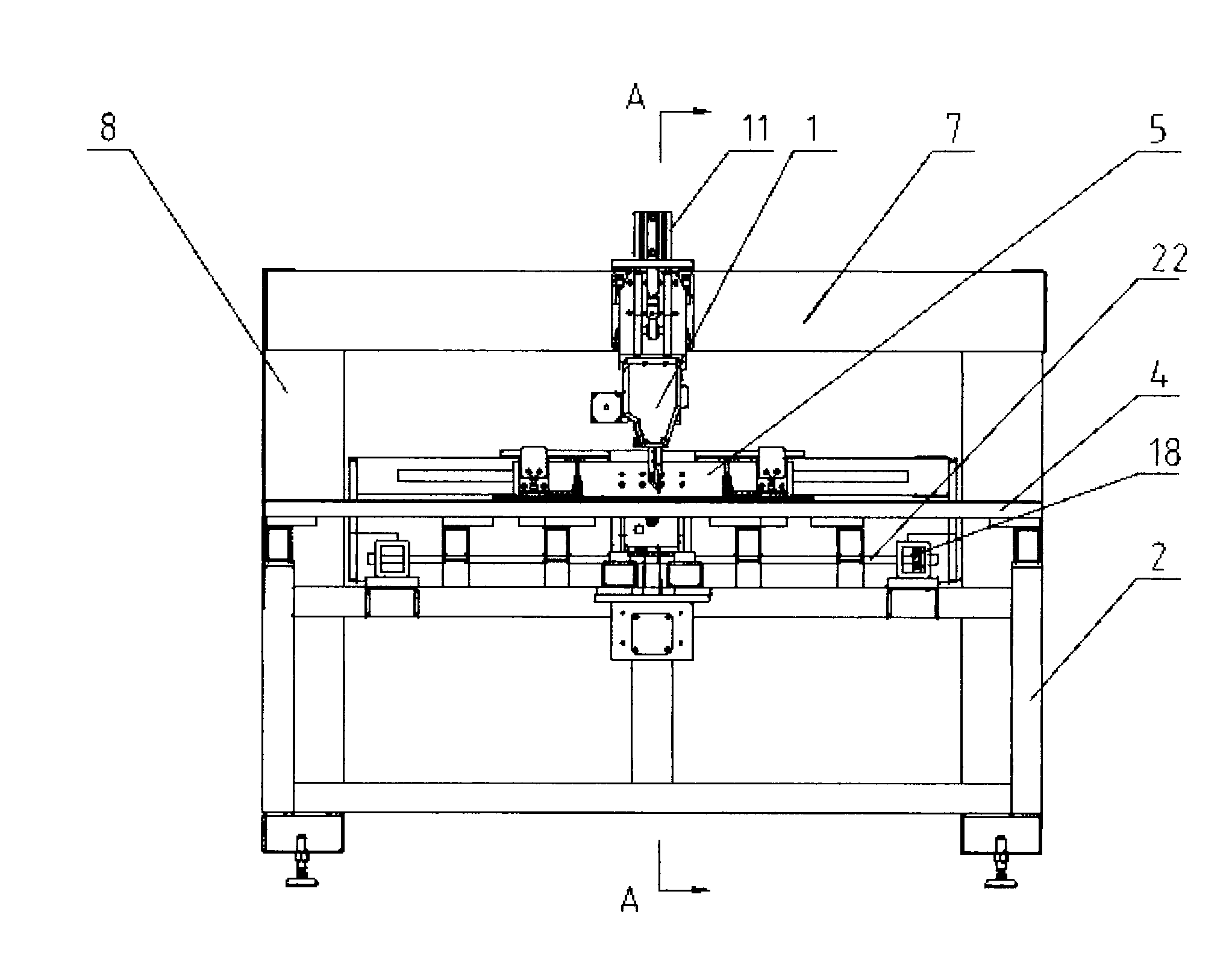

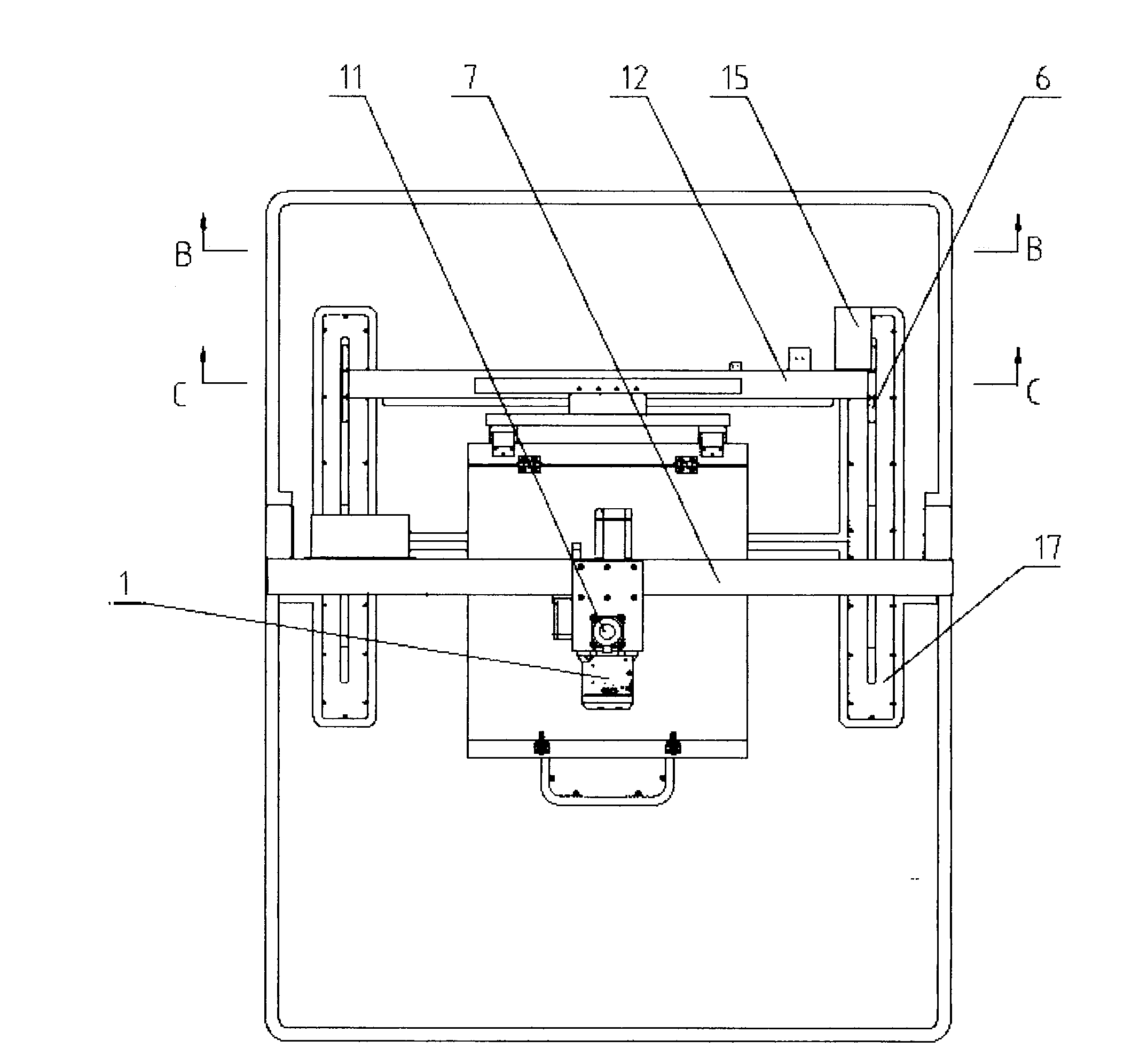

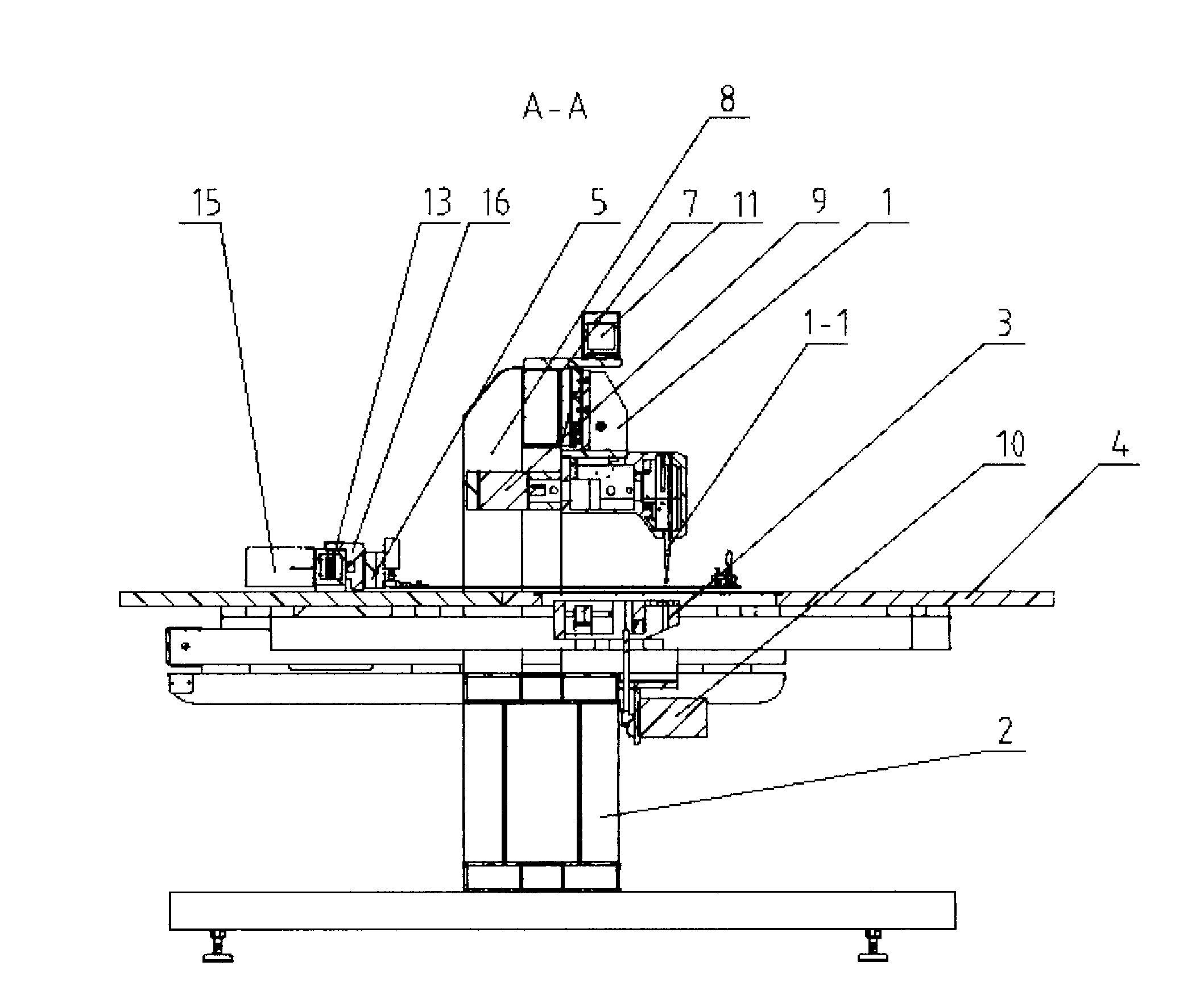

[0017] like Figure 1-5 As shown, a gantry-type large-format sewing pattern machine includes a machine head 1, a frame 2, a hook structure 3, a lateral movement module, a longitudinal movement module, a control system and a table mounted on the frame 2 4 and the binder frame assembly 5 above the platen 4, the lateral motion module is mounted on the longitudinal motion module through the connecting plate 6 to move longitudinally, and the binder frame assembly 5 is mounted on the lateral motion module to be movable laterally , the longitudinal movement module is fixed on the frame 2, the hook hole of the rotary hook structure 3 is aligned with the machine needle of the machine head 1, and also includes a crossbeam 7, the two sides of the frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com