Intelligent FRP (Fiber Reinforced Polymer) composite rib based on carbon fiber distribution type sensing and large-scale production process thereof

A production process, carbon fiber technology, applied in the field of intelligent FRP composite ribs and its large-scale production process, can solve the difficulty of leading out the wires of carbon fiber sensing cores, affect product yield and performance stability, and reduce distributed sensing Test accuracy and other issues to achieve the effect of improving sensing performance and mechanical properties, small changes in industrial production processes and equipment, and improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In conjunction with the legend, the specific implementation process of the present invention is described in more detail:

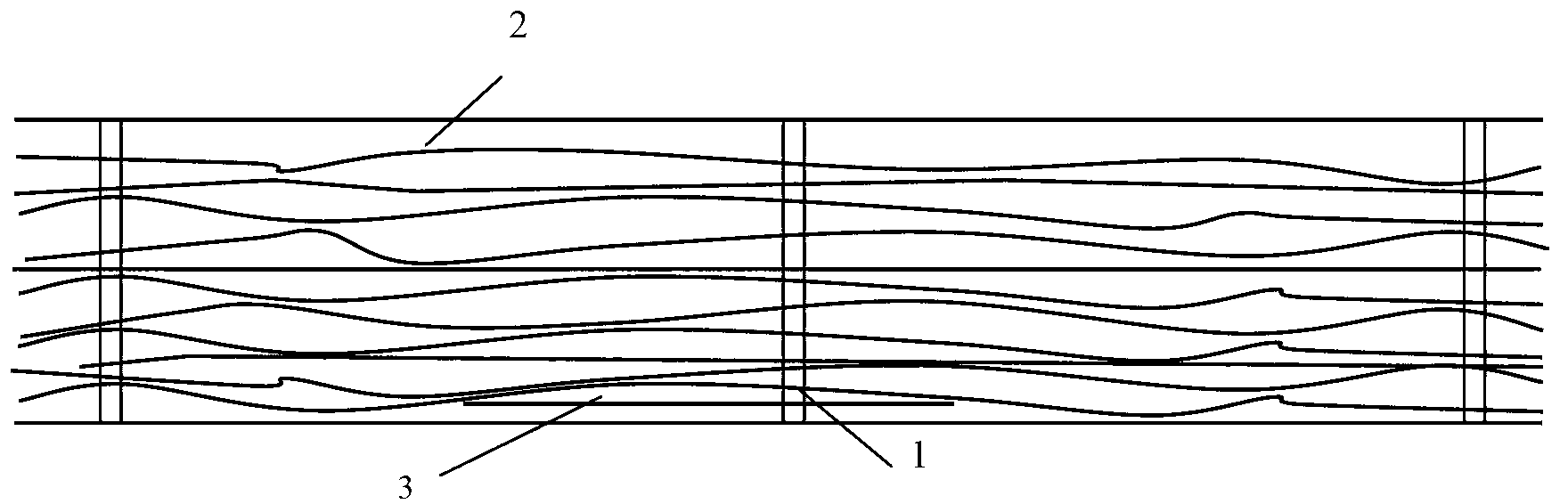

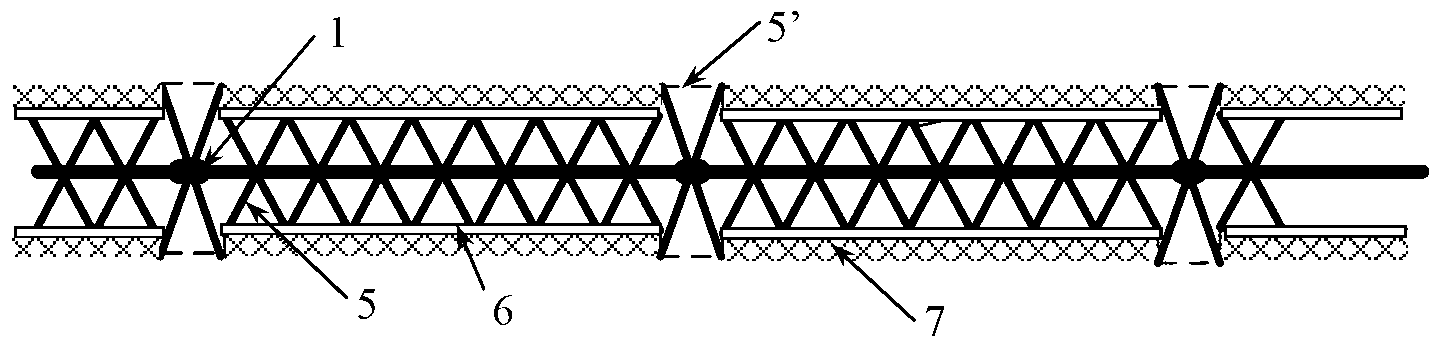

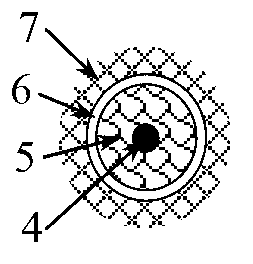

[0049] attached Figure 7 It is the structural diagram of intelligent FRP composite rib 23 of the present invention, see also figure 2 and image 3 , is mainly composed of two parts, that is, the long-gauge carbon fiber sensing core 8 and the outer cladding FRP layer 29 . Wherein the long-gauge carbon fiber sensing core 8 is located in the middle of the intelligent FRP composite rib 23, and the measuring electrode 1 is firmly anchored to the long-gauge carbon fiber sensing core 8 and drawn out by the wire 32, and is bonded with the outer cladding FRP layer of the periphery to form a On the whole, the rubber barrier layer completely separates the gauge length of the sensing part from the resin and fiber 20 to ensure the free expansion and contraction of the long gauge carbon fiber sensing core 8 in the gauge section so as to form a uniform stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com