Energy-saving and environmentally-friendly boiler

An energy saving, environmental protection and boiler technology, applied in the field of boilers, can solve problems such as failure to meet environmental protection requirements, high boiler exhaust temperature, and large heat loss of flue gas, and achieve good smoke and dust removal, low exhaust temperature and high thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

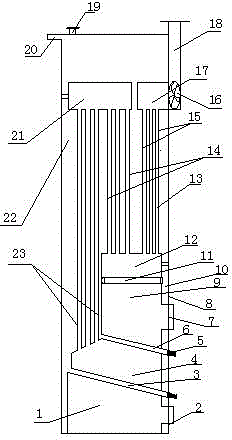

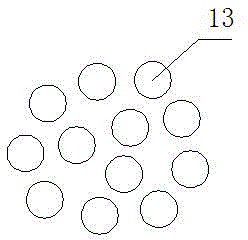

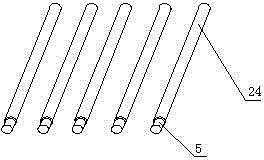

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Accompanying drawing is the specific embodiment of the present invention. This embodiment is an energy-saving and environment-friendly boiler, including a furnace shell 8, a furnace, a water tank 22, a fire grate, a water jacket 10, a dust box, a flue exhaust duct, and a chimney 18, and is characterized in that: the furnace wall and the furnace shell 8 A sandwich water jacket 10 is provided between them, and the water jacket 10 communicates with the boiler water tank 22. The furnace is divided into a combustion chamber 9, a counter-burning chamber 4 and a residue chamber 1 by an upper grate 6 and a lower grate 3. , the top of the combustion chamber 9 is provided with a heat exchange tube 11 connected to the water tank 22 and the water jacket 10, the front end of the combustion chamber 9 is provided with a feeding port 7, the front end of the resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com