Cement solidification method of nuclear power waste

A nuclear power waste and cement solidification technology, applied in the field of nuclear power, can solve problems such as waste overflow, solidified body performance not meeting standard requirements, waste secondary pollution, etc., to achieve waste minimization, cement solidified body performance to meet, Effective waste disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

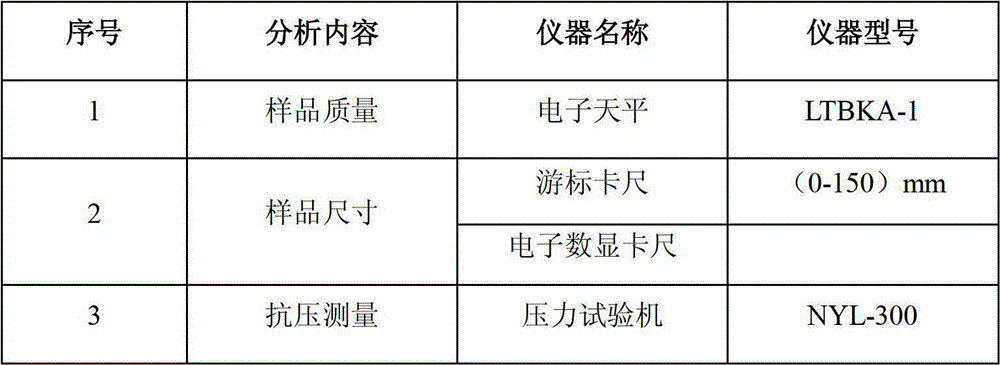

[0037] Embodiment 1, adopted the method of the present invention to carry out solidification treatment test to radioactive concentrate in certain nuclear power plant, be specifically described as follows:

[0038] 1. Concentrate cement curing formula for radioactive curing

[0039] 1.1 Composition and addition sequence of concentrated liquid cement curing formula

[0040] order of addition

Composition

1

Concentrate

2

Admixture

3

lime

4

cement

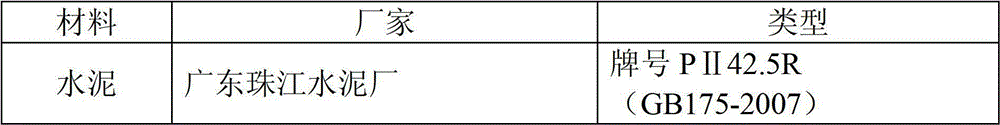

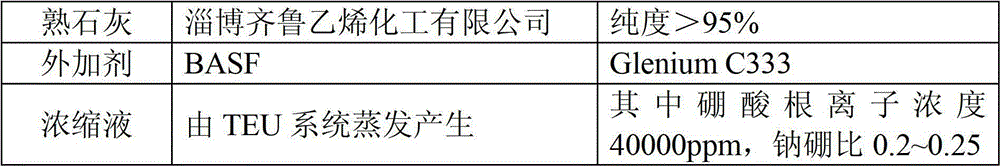

[0041] 1.2 Curing material and model

[0042]

[0043]

[0044] 1.3 Corresponding data of each raw material

[0045] waste source item

unit

range and value

Borate ion concentration

ppm / l

chemical analysis measurement

total salt

g / Kg

chemical analysis measurement

mol / Kg

chemical analysis measurement

mol / Kg

chemical analysis measurement...

Embodiment 2

[0087] Embodiment 2, a cement curing method for nuclear power waste, the specific steps are the same as in Embodiment 1, after obtaining the slurry, use The standard small test mold obtains multiple cured body samples.

[0088] 1. The parameters of raw materials and waste to be treated are shown in Table 10:

[0089] Table 10 Concentrate to be treated, raw material parameter list

[0090] Waste to be processed, raw materials

unit

parameters

Borate ion concentration

ppm / l

40000

total salt

g / Kg

229.8

mol / Kg

0.1

Sulfate ion concentration

mol / Kg

0.1

Lime and borate ion excess multiple

-

1.8

Lime and phosphate ion excess multiple

-

1.2

Lime and sulfate ion excess multiple

-

0.8

Concentrate density

g / cm 3

1.1

Water-cement ratio (water:lime)

-

0.35

External ash ratio (admixture: lime)

-

2....

Embodiment 3

[0119] Embodiment 3, a cement curing method for nuclear power waste, the specific steps are the same as in Embodiment 1, after obtaining the slurry, use The standard small test mold obtains multiple cured body samples.

[0120] 1. The parameters of raw materials and waste to be treated are shown in Table 17:

[0121] Table 17 Parameters of raw materials and waste to be treated

[0122]

[0123] According to the table above, the concentrated liquid cement curing formula is obtained:

[0124] cement

Concentrate

slaked lime

Admixture

Total

417.22

227.52

63.5

4.2

692.47

[0125] The volume containment rate of the concentrated solution of this example is 56%, which has increased by 16% on the existing basis.

[0126] 5.2 Compressive strength See Table 18 for the compressive strength test results of the samples.

[0127] Table 18 Concentrated liquid cement solidified body small test mold sample compressive strength tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com