Method for manufacturing wafer-level light-emitting diode (LED)

A technology of a light-emitting diode and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of waste of manufacturing cost, insufficient concentration of color temperature distribution, and inability to manufacture white LEDs with a variety of specific color temperatures. The effect of reducing production costs and solving commercial inventory pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

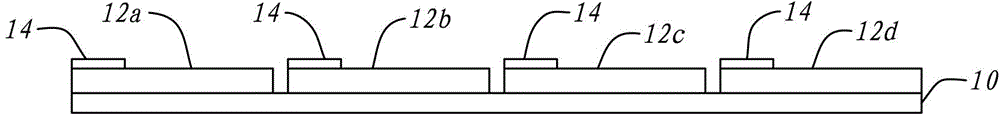

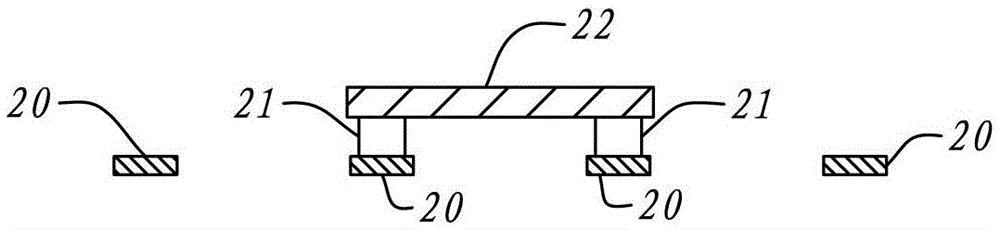

[0041] The present invention proposes a wafer-level light-emitting diode manufacturing method, which uses shielding and shielding sheets to cover the crystal grains that do not need to be sprayed, so as to achieve the purpose of partially spraying fluorescent powder on the crystal grains whose brightness and wavelength meet the requirements.

[0042] When the process method of the present invention is repeated, white light emitting diodes with different specific color temperatures can be fabricated on a single wafer (or substrate) according to the photoelectric characteristic requirements of different crystal grains.

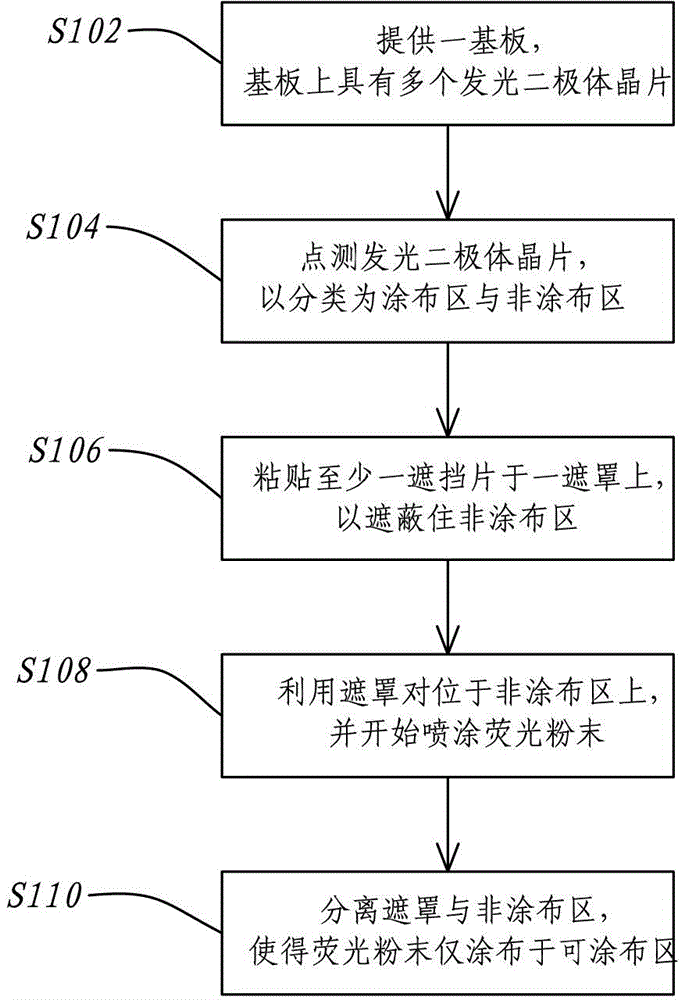

[0043] Please refer to figure 1 , is a flow chart of steps of a method for manufacturing a wafer-level light-emitting diode according to an embodiment of the present invention. The method includes steps S102, S104, S106, S108, and S110. The following is to explain the technical idea of the present invention, please refer to Figure 2 to Figure 6 shown.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com