Motor and controller assembly

A technology of controllers and components, applied in the direction of electric components, connected with control/drive circuits, electrical components, etc., can solve problems such as high heat dissipation cost, limited heat dissipation effect, and large electromagnetic noise, so as to improve working torque and work efficiency , Expand the driving frequency range, improve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

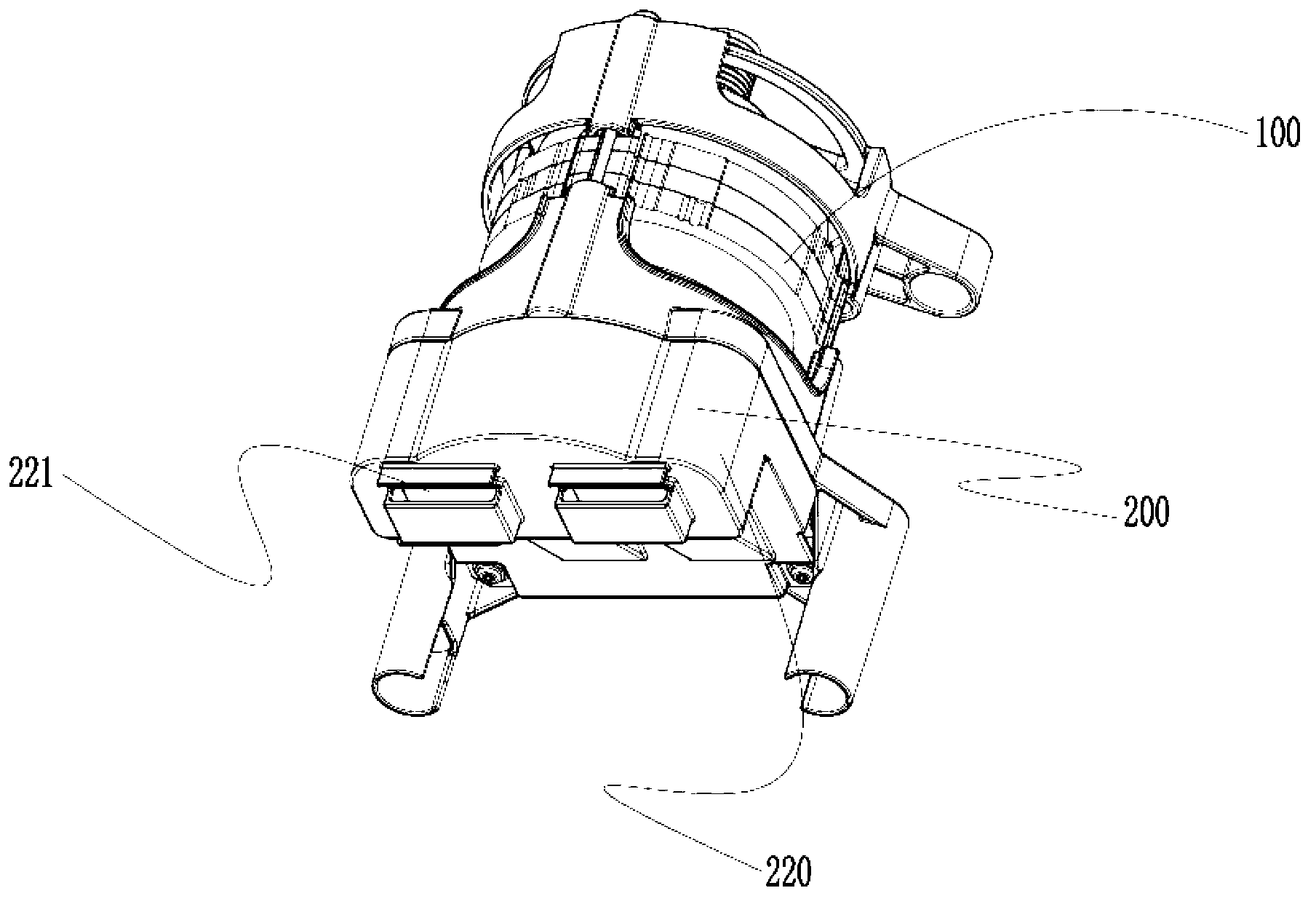

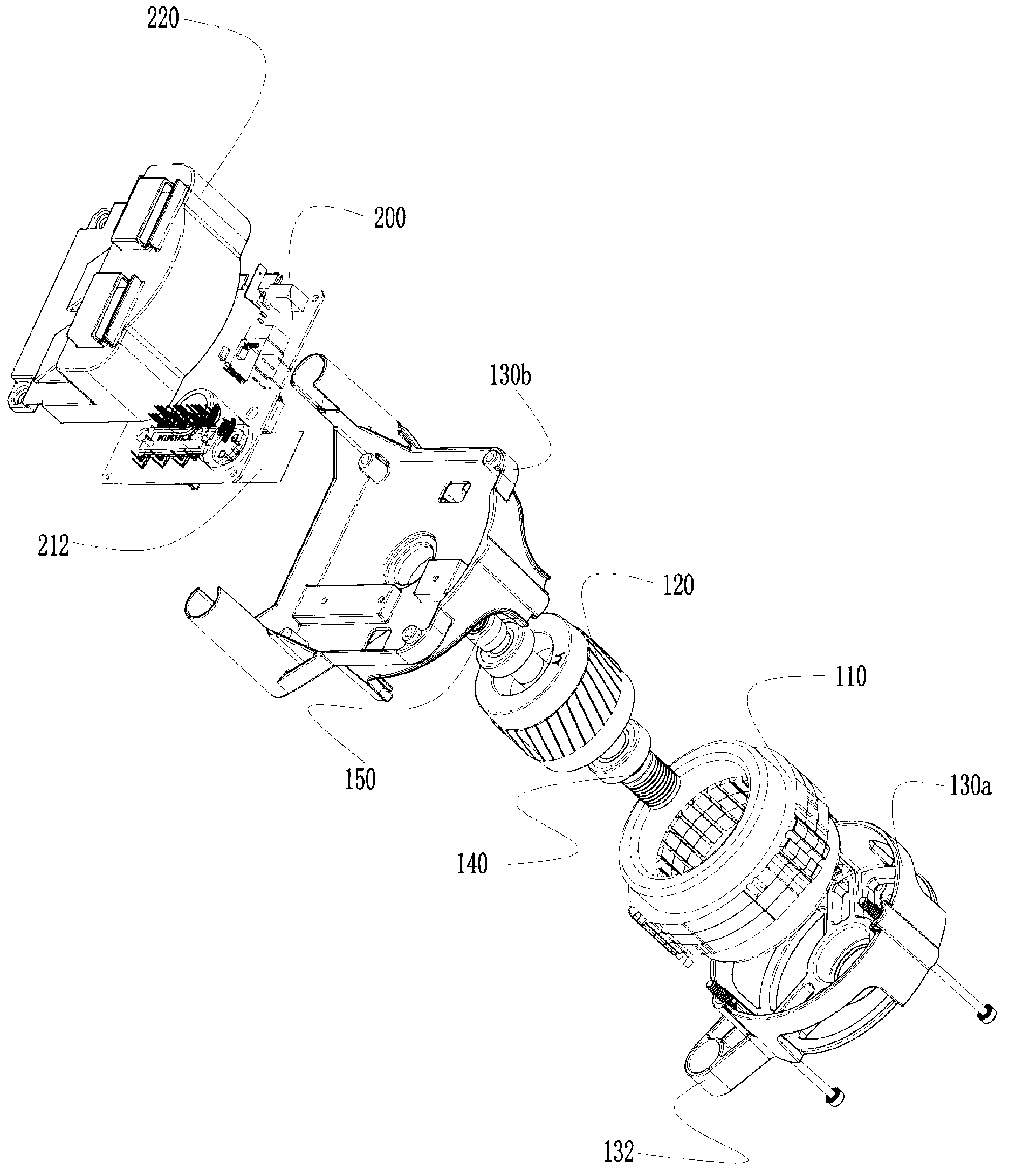

[0074] Embodiment 1, see figure 1 , 2 , and combined with the reference image 3 , 4 5. A motor and controller assembly, including a motor 100, a controller 200 for controlling the operation of the motor, the controller 200 is directly installed on the motor 100, the motor includes a stator assembly 110, and a rotor assembly 120 integrated with the rotating shaft 140 1. Two front end covers 130a and rear end cover 130b for fixing the stator assembly 110, the rotor assembly 120 can rotate relative to the stator assembly 110, wherein: one side of the controller 200 is fixedly installed on the outer side of the rear end cover 130b The heating element 210 of the controller 200 is arranged on the controller panel 200a near the outer side of the rear end cover 130b, and the matching part 131 fixedly connected with the heating element 210 is arranged on the outer side of the rear end cover 130b, and the heating element 210 passes through the heat conducting sheet 212 It is fixedly...

Embodiment 2

[0075] Embodiment 2. A motor and controller assembly. The external component is a washing machine. The other end of the rotating shaft 140 is connected to a pulley (not marked in the figure), and the power is transmitted to the reduction mechanism through the pulley, and then through the reduction The structure is transmitted to the washing shaft and dehydration shaft of the washing machine; the rotating shaft can also selectively transmit power to the washing shaft and dehydration shaft of the washing machine directly through the clutch mechanism. All the other can be with embodiment 1.

Embodiment 3

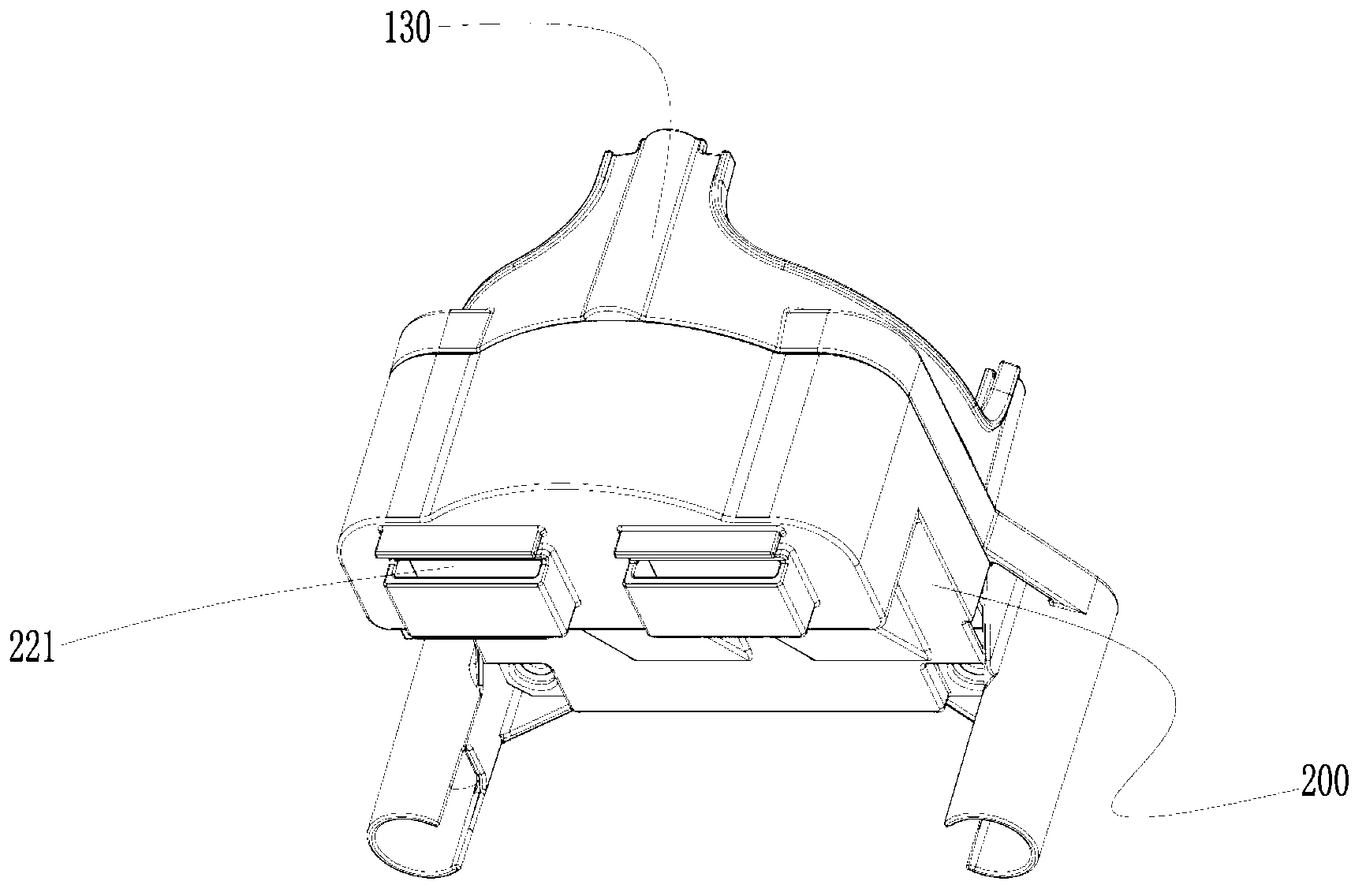

[0076] Embodiment 3, see image 3 , 4 , 5, and combined with reference figure 1 , 2 , a motor end cover and controller assembly, the controller 200 includes software to control the operation of the motor 100, the controller 200 is directly installed on the end cover 130, wherein: one side of the controller 200 is fixedly installed on On the outer side of the end cover 130, the heating element 210 of the controller 200 is arranged on the controller panel 200a close to the outer side of the end cover 130, and the outer side of the end cover 130 is provided with a matching part 131 fixedly connected with the heating element 210 to generate heat. The element 210 is fixedly connected with the mating part 131; the mating part 131 is a boss, and the shape of the boss matches the shape of the heating element 210 of the controller; the controller 200 is a single panel, specifically the The controller panel 200a near the outside of the end cover 130 is a wire distribution surface, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com