Vertical pipe type sludge-water separation treating device

A mud-water separation and treatment device technology, applied in the direction of separation method, sedimentation separation, settling tank, etc., can solve the problems of poor treatment effect, and achieve the effect of facilitating digestion, convenient implementation, and stable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

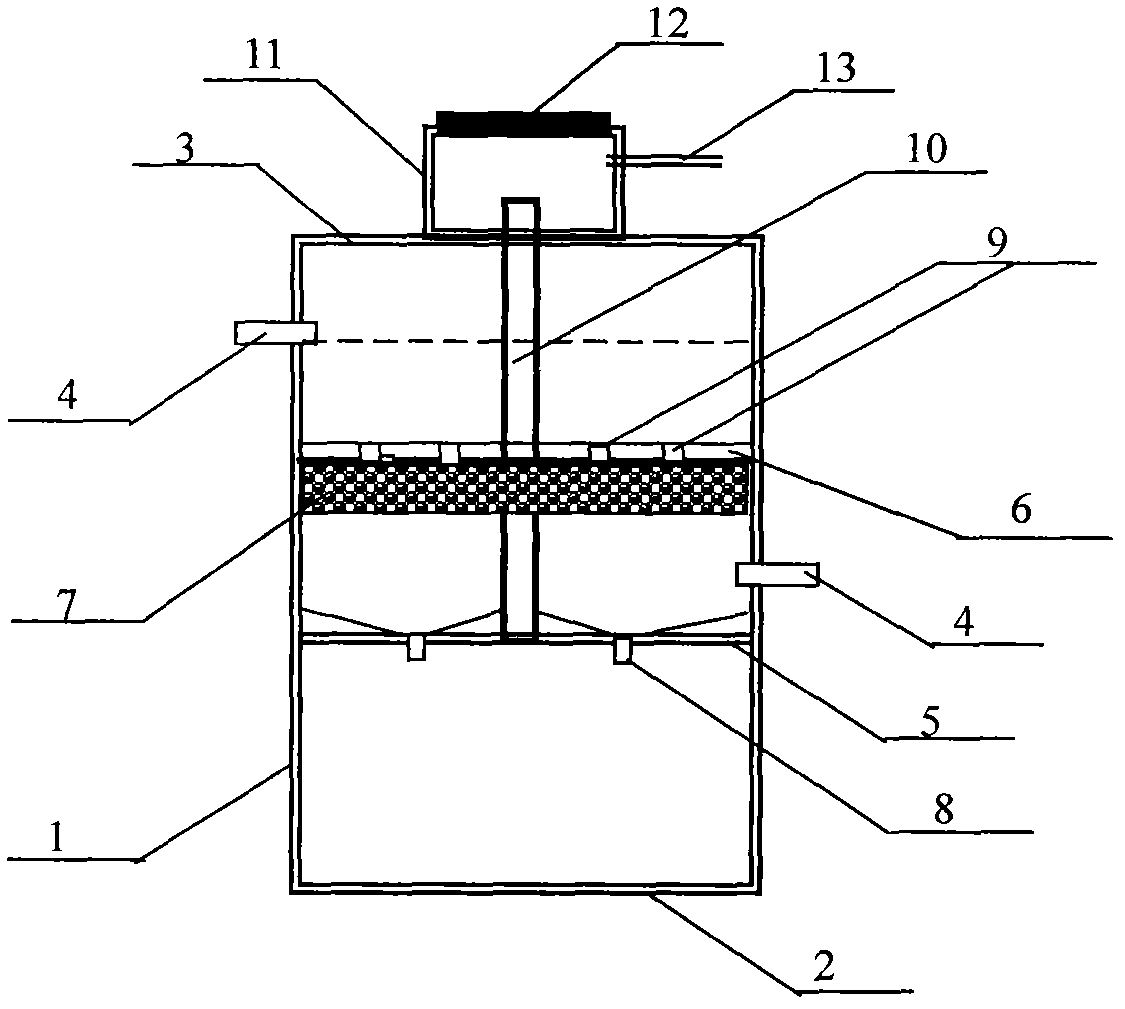

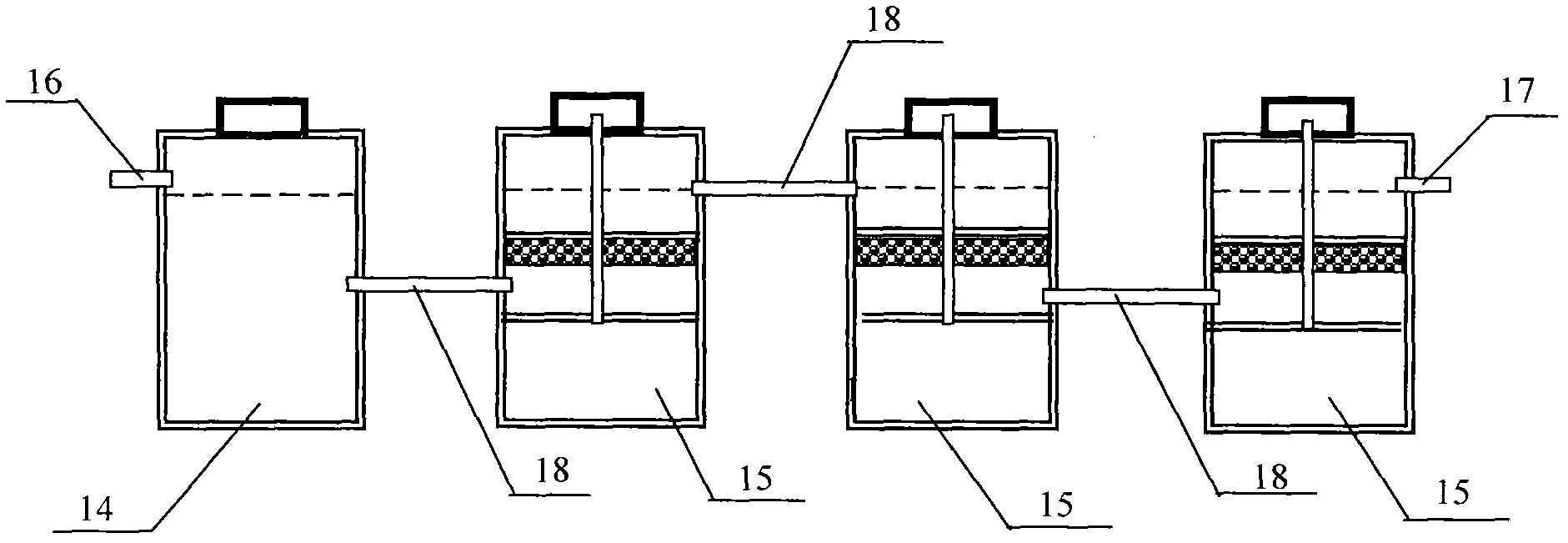

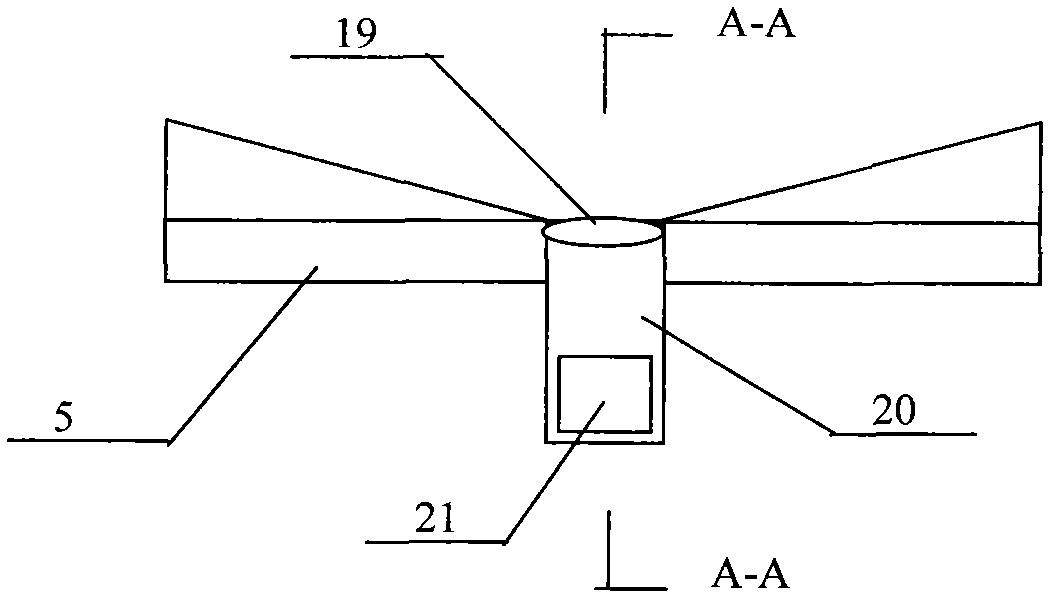

[0018] like figure 1 , 2 , 3, 4, the embodiment shown is to be made of a settling tank unit 14 and three standpipe type mud-water separation treatment units 15 connected in series, the pool wall of the standpipe type mud-water separation treatment unit is pipe wall 1, the pool of the pond body Bottom plate 2, the upper part is pool roof plate 3, and there is an inspection well on the pool roof plate. The interior of each mud-water separation treatment unit is separated by a space partition plate 5 and a filler placement plate 6. Below the filler placement plate is a suspended filler 7 and a space separation plate 5 There is a sediment guide pipe 8 on it, and a water hole 9 on the packing placement plate 6. The upper opening of the clearing pipe 10 is opened at the inspection well, and the lower opening is opened at the space separation plate 5, and the upper part of the tank body packing placement plate 6 And the water inlet and outlet pipe 4 is set between the filler placeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com