High concentration sericite master batch and preparation method and application thereof

A sericite, high-concentration technology, applied in the direction of mechanical equipment, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as unsatisfactory results, shorten the processing route, save energy, and improve heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

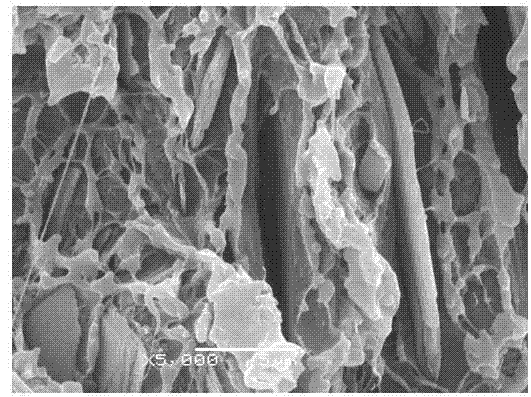

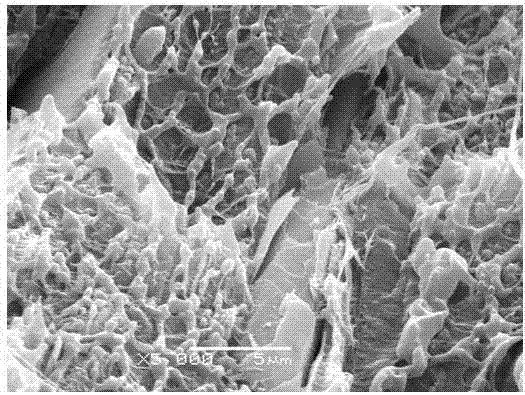

Image

Examples

Embodiment 1

[0032] Material:

[0033] (1) The mass ratio of each component in the high-concentration sericite material is: sericite powder (wet process sericite powder, particle size 200 mesh, produced by Anhui Chuzhou Wenlong Sericite Co., Ltd., the same below) 80 parts; resin Acid (first grade, Guangxi Xing'an County Rosin Factory, the same below) 1 part, wherein the resin acid is resin acid extracted from rosin, which is C 19 h 29 A mixture of organic carboxylic acids of isomers of COOH; the dispersant is 5 parts of oxidized PE wax dispersant (PEWO-0503, produced by Nanjing Tianshi Micro Powder Co., Ltd., the same below); antioxidant 1010 (Jinhai Yabao Co., Ltd. Production, the same below) 0.01 parts; recycled HDPE (milk bottle crushed recycled materials, provided by Jiangsu Shengtong Environmental Engineering Company, the same below) 20 parts.

[0034] The preparation method of high concentration sericite material:

[0035] Add sericite powder into the high-speed mixer and raise th...

Embodiment 2

[0041] Material:

[0042] (1) The mass ratio of each component in the high-concentration sericite material is: 150 parts of sericite powder, 10 parts of resin acid, 20 parts of oxidized PE wax, 0.1 part of antioxidant 1010, and 30 parts of recycled HDPE, of which Resin acid is resin acid extracted from rosin, which is C 19 h 29 A mixture of organic carboxylic acids that are isomers of COOH. High concentration sericite material preparation method is the same as embodiment 1

[0043] (2) The mass ratio of each component of the hollow winding pipe is: 15 parts of high-concentration sericite material, 100 parts of recycled HDPE, and 0.2 part of black mother.

[0044] Preparation method of hollow wound pipe: same as in Example 1.

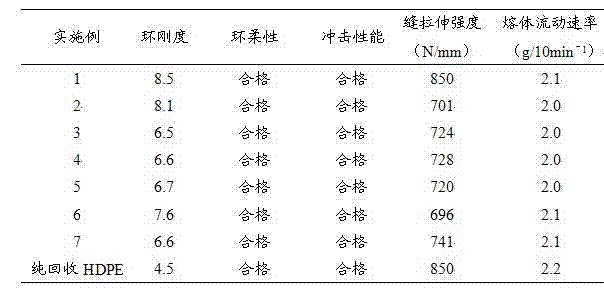

[0045] For the hollow wound pipe prepared in Example 2, performance tests such as ring stiffness were carried out according to GB / T14152-2004. Test results: see Table 1.

Embodiment 3

[0047] Material:

[0048] (1) The mass ratio of each component in the high-concentration sericite material is: 120 parts of sericite powder, 7 parts of resin acid, zinc stearate (industrial grade, produced by Jiangsu Nantong Huizhi Chemical Co., Ltd., the same below) 15 parts, 0.06 parts of antioxidant 1010, and 30 parts of recovered HDPE.

[0049] (2) The mass ratio of each component of the hollow pipe is: 20 parts of high-concentration sericite material, 100 parts of recycled HDPE, and 0.5 part of black mother.

[0050] The preparation method of high-concentration sericite material: the same as Example 1, the difference is that after adding sericite powder in the high-speed mixer, the temperature is raised to 108 ° C, and after preheating for 15 minutes, resin acid and antioxidant 1010 are added and stirred at high speed Mix for 8 minutes, then add zinc stearate and recovered HDPE, stir for about 20 minutes, and discharge.

[0051] Preparation method of hollow wound pipe: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com