Glass fiber reinforced polypropylene compound material and preparation method thereof

A glass fiber and composite material technology, applied in the field of glass fiber reinforced polypropylene composite material and its preparation, can solve the problems of oil resistance, increase product cost, reduce material service life, etc., achieve high heat resistance and increase tensile strength , the effect of preventing bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

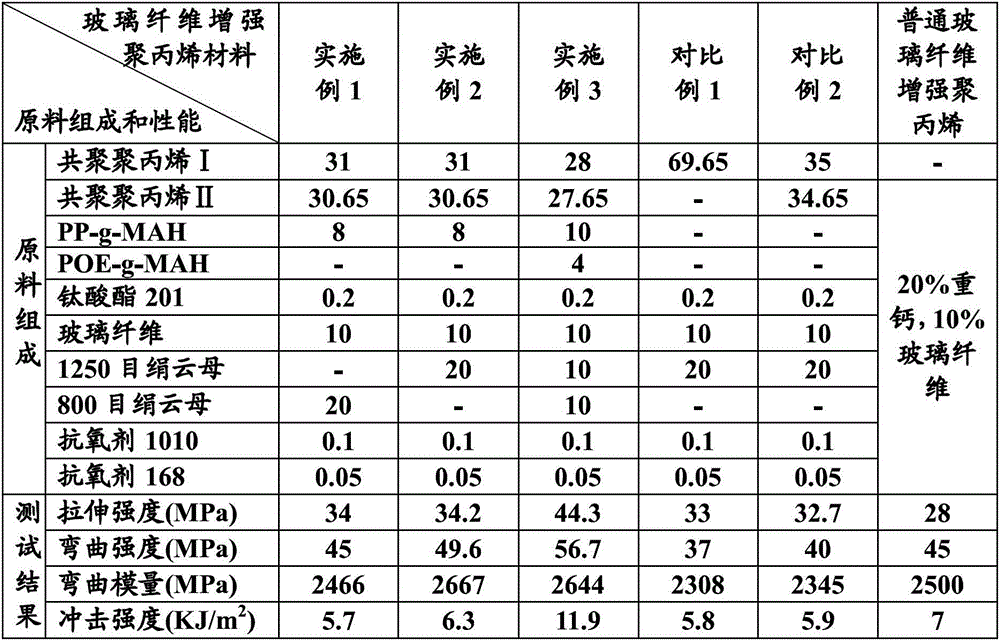

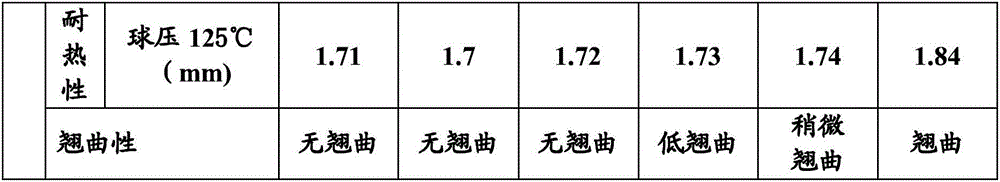

Embodiment 1

[0041] This embodiment provides a glass fiber reinforced polypropylene composite material, its raw material composition and dosage refer to Table 1, wherein: the copolymerized polypropylene I adopts PP AR564 (purchased from sumitomo), and the copolymerized polypropylene II adopts PP M1600 (purchased from Korea Hyundai ). The diameter of the glass fiber is 8-17 microns (model ERS200-13-T635B, purchased from Taishan Glass Fiber Co., Ltd.).

[0042] Compatibilizer: homopolypropylene grafted maleic anhydride (PP-g-MAH) (purchased from ExxonMobil Chemical), semi-crystalline POE grafted maleic anhydride (POE-g-MAH) (purchased from Egypt ExxonMobil Chemical).

[0043] The preparation method of glass fiber reinforced polypropylene composite material is as follows: Weigh the material according to the number of components in Table 1, mix it through a mixer, add it to a twin-screw extruder, add glass fibers from the fiber port, extrude and granulate, and make A glass fiber reinforced p...

Embodiment 2~3

[0049] Examples 2-3 respectively provide glass fiber reinforced polypropylene composite materials according to the present invention, whose main raw material composition is shown in Table 1, and a lubricant whose weight is about 0.1% of the total weight of the raw materials listed in the table is also added. A glass fiber reinforced polypropylene composite material was prepared in the same manner as in Example 1. The performance data of the obtained composite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com