Liquid oral composition and method for producing same

A manufacturing method and composition technology, applied in the field of non-alcoholic emulsified liquid oral compositions, can solve the problem of unpredictable appearance stability and use feeling of emulsion mixed preparations, maintaining good appearance stability of preparations, and not revealing emulsion mixing and other issues, to achieve the effect of excellent retention of realism, excellent appearance stability, and good appearance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

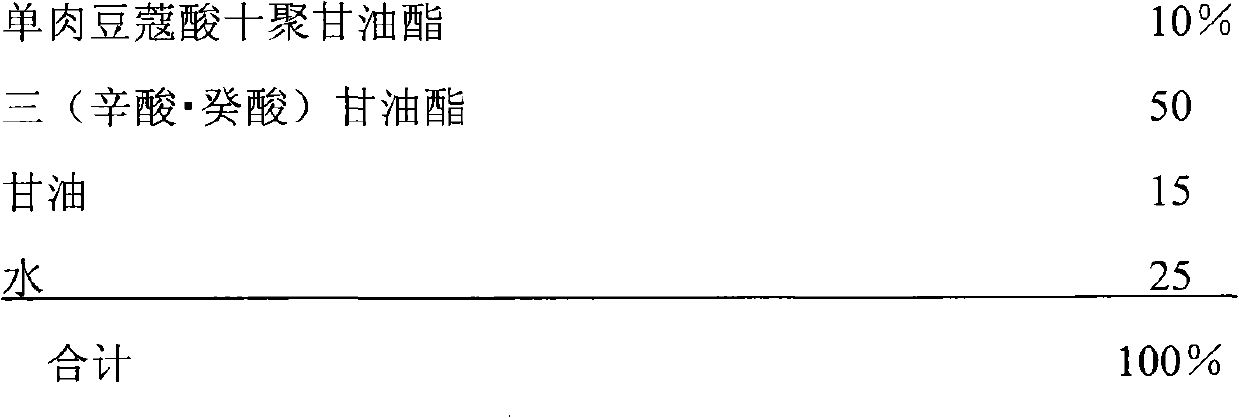

[0119] Hereinafter, the present invention will be specifically described with reference to experimental examples, examples, and comparative examples, but the present invention is not limited to the following examples. The mixing amount is pure fraction conversion.

[0120] The preparation of the liquid oral composition of each example used polyoxyethylene (60) hydrogenated castor oil (manufactured by Nikko Chemical Co., Ltd., the average number of added moles of ethylene oxide is 60), POE (80) hydrogenated castor oil (Japanese Photochemical Co., Ltd., the average number of added moles of ethylene oxide is 80), emulsion (average particle diameter: 200 nm, NET-TE-50, manufactured by Nikko Chemical Co., Ltd.), glycerin (100%, manufactured by Sakamoto Pharmaceutical Co., Ltd.), propylene glycol ( Asahi Glass Co., Ltd.), polyethylene glycol #400 (manufactured by Lion Chemical Co., Ltd.), citric acid (manufactured by Fuso Chemical Co., Ltd.), sodium citrate (manufactured by Fuso Che...

experiment example 1

[0143] Liquid oral compositions (mouthwashes) having the compositions shown in Tables 1 to 6 were prepared according to the usual method, and finally the emulsion was dispersed, and the following evaluations were performed. The results are shown in Tables 1-6.

[0144] Appearance stability evaluation:

[0145] The 450ml sample liquid oral composition is filled in the PET container (polyethylene terephthalate container Yoshino industry manufacture) of full scale 450ml, by contrast substance (the just manufactured product of embodiment 1) For comparison, the stability after storage in a constant temperature tank at 50°C for 3 months or after storage in a constant temperature tank at -10°C for 3 months was visually judged based on the following criteria.

[0146] Evaluation criteria for appearance stability (50°C, 3 months)

[0147] ⊚: There is no change in the color tone of the preparation.

[0148] ◯: The color tone of the preparation is only a little faded, but it is still...

experiment example 2

[0158] The liquid oral compositions in Tables 1 to 6 were evaluated for the stimulation of menthol at the time of gargling, the persistence of the refreshing feeling after gargling, the real feeling of retention, and the sticky feeling. The results are shown in Tables 1-6.

[0159] Evaluation method:

[0160] Ten subjects took 10 ml of the sample (liquid oral composition) in their mouths and rinsed their mouths for 30 seconds, and evaluated the presence or absence of menthol stimulation during mouthwashing, and the refreshing feeling after gargling with the preparation for 10 minutes on a scale of 4 or 5 as follows The average score of 10 people was judged according to the following criteria for persistence, lingering realism, and non-stickiness.

[0161] (a) Stimulation of menthol

[0162] scoring benchmark

[0163] 5 points: Stimulation is very weak

[0164] 4 points: weak stimulus

[0165] 3 points: weak stimulus

[0166] 2 points: strong stimulation

[0167] 1 point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com