Energy-saving ultrasonic dish washing machine

An ultrasonic and dishwasher technology is applied in the field of energy-saving ultrasonic dishwashers to achieve the effects of reducing operating costs, saving electricity and reducing economic pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

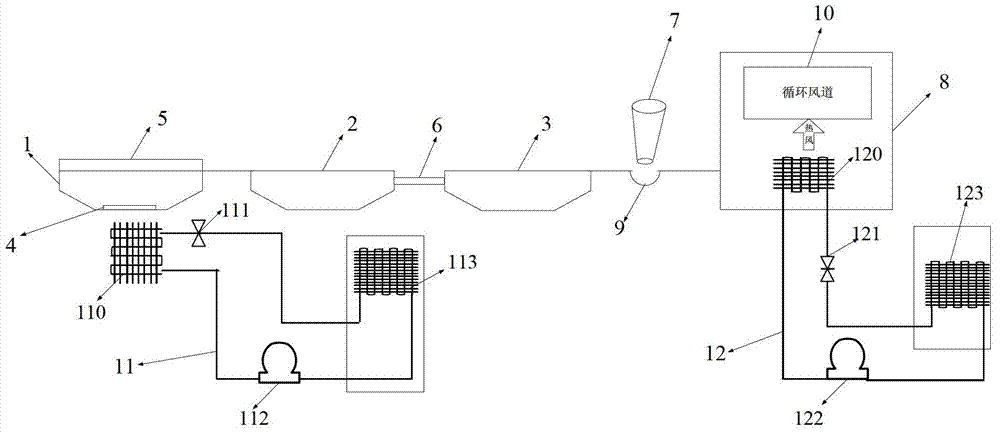

[0033] figure 1 A schematic structural diagram of an energy-saving ultrasonic dishwasher in Embodiment 1 is shown. like figure 1 As shown, the energy-saving ultrasonic dishwasher includes a cleaning device, a drying device, a first heating device for providing heat energy for the cleaning tank, and a second heating device for providing heat energy for the drying device.

[0034] The cleaning device includes a cleaning tank 1, a middle bleaching tank 2 and a net bleaching tank 3 arranged in sequence. An ultrasonic generator 4 is arranged in the cleaning tank 1 . The top of the cleaning tank 1 is provided with a thermal insulation cover 5 for preventing heat loss in the cleaning tank 1 . The clean water inlet (not shown in the figure) is arranged on the net drift tank 3, and the overflow pipe (not shown in the figure) is arranged on the intermediate drift tank 2 . The middle drift tank 2 and the net drift tank 3 are connected through a connector 6 .

[0035] The drying devi...

Embodiment 2

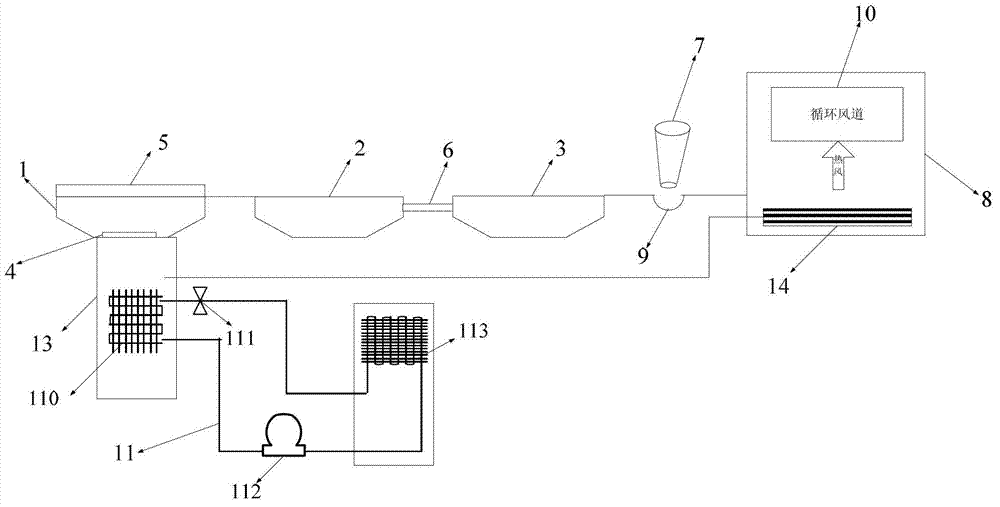

[0042] The structure of the energy-saving ultrasonic dishwasher in Embodiment 2 is basically similar to the structure of the energy-saving ultrasonic dishwasher in Embodiment 1, the difference is that the first heating device and the second heating device in this embodiment are the same as those in Embodiment 1. The structures of the first heating device and the second heating device are different. In this embodiment, the first heating device is the first heat pump 11 and the first water tank 13 , and the second heating device is the first heat exchanger 14 . In this embodiment, the first heat pump 11 is an air source heat pump or a water source heat pump including a first condenser 110 , a first throttle valve 111 , a first compressor 112 and a first evaporator 113 . The condenser of the first heat pump 11 is arranged at the bottom of the first water tank 13 , and the high-temperature and high-pressure gas in the upper part of the first water tank 13 is used for heating the c...

Embodiment 3

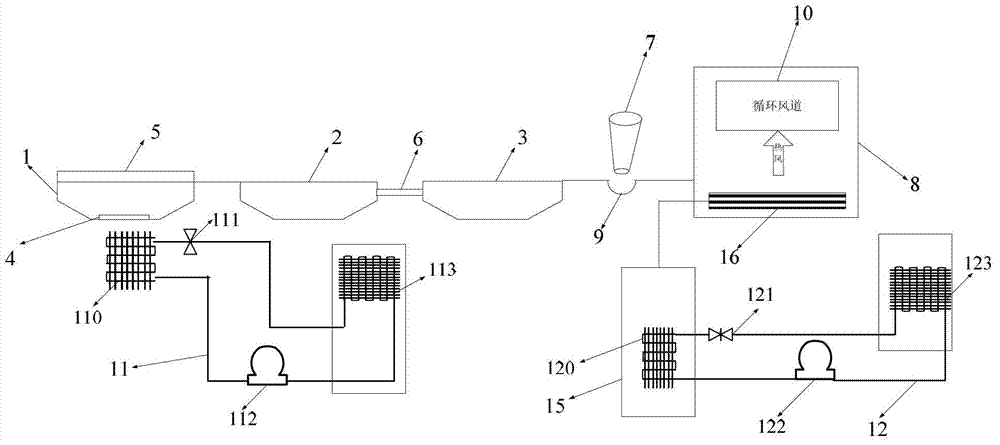

[0045] The structure of the energy-saving ultrasonic dishwasher in Embodiment 3 is basically similar to the structure of the energy-saving ultrasonic dishwasher in Embodiment 1, the difference is that the first heating device and the second heating device in this embodiment are the same as those in Embodiment 1. The structure of the second heating device is different. In this embodiment, the second heating device is a combination of the second heat pump 12 , the second water tank 15 and the second heat exchanger 16 . The structure of the second heat pump 12 is the same as that of the second heat pump 12 in Embodiment 1, that is, a water source heat pump including a second condenser 120 , a second throttle valve 121 , a second compressor 122 and a second evaporator 123 . Wherein, the second condenser 120 is placed in the second water tank 15, and is used for heating the water in the second water tank 15, and the hot water in the second water tank 15 is converted into hot air by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com