Dual-pump circulating stirring dispensing process

A pump circulation and dispensing technology, applied in mixer accessories, dissolving, mixer and other directions, can solve the problems of high cost, long mixing time and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

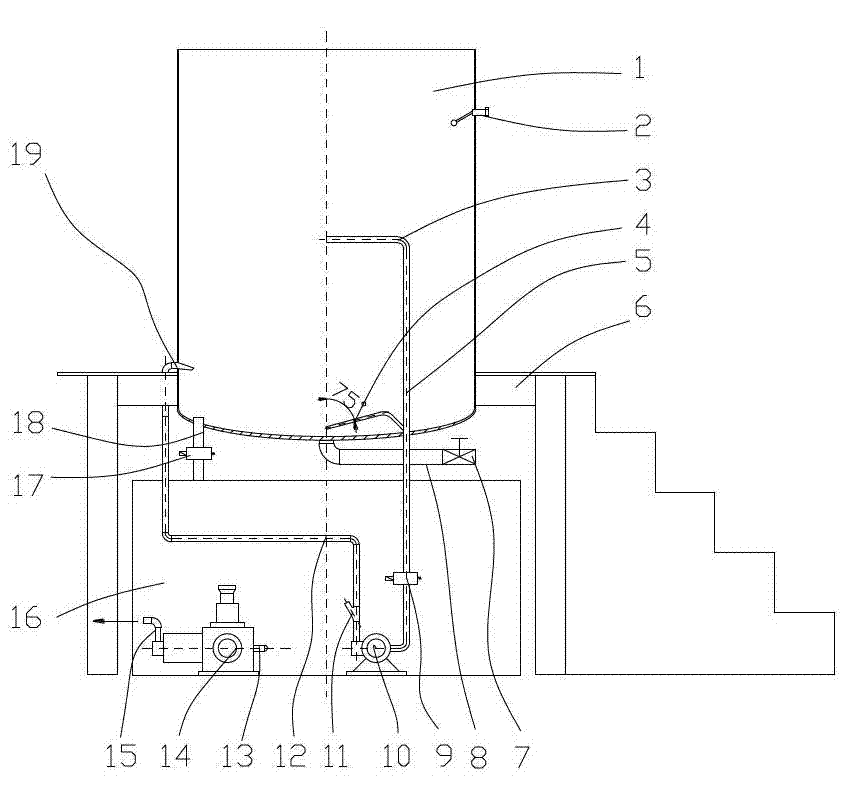

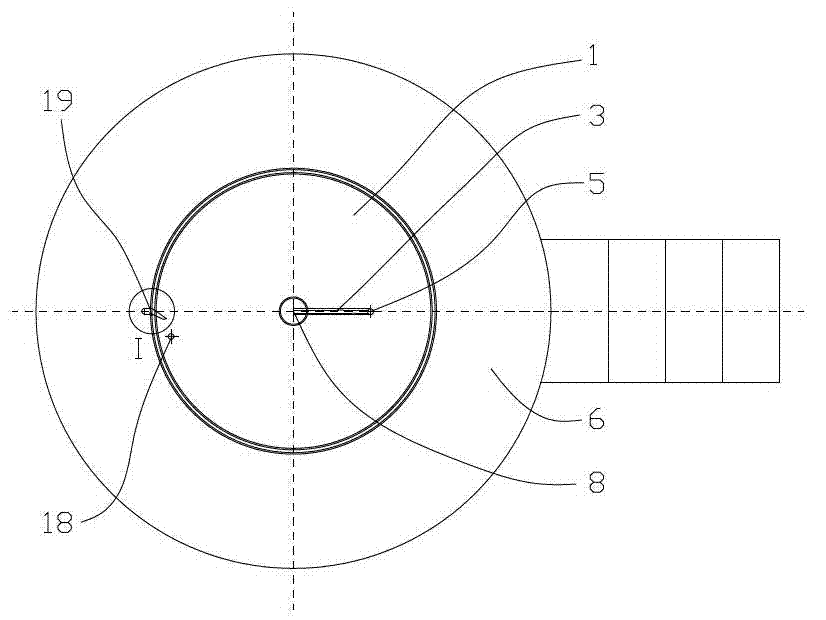

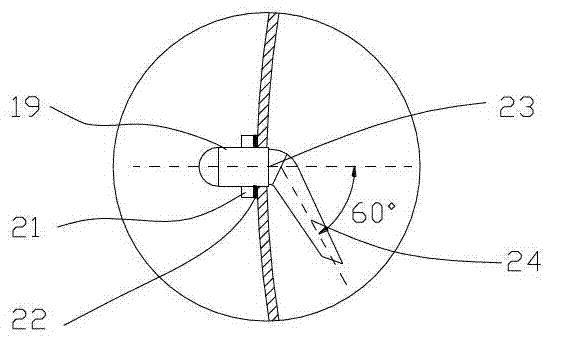

Embodiment 1

[0043] The double-port parallel pump circulation stirring dispensing process includes: dispensing tank 1, liquid level sensor 2, upper suction pipe 3, lower suction pipe 4, plastic pump suction pipe 5, workbench 6, emptying valve 7, emptying pipe 8, electromagnetic Valve A9, plastic pump 10, check valve 11, stirring pipe 12, discharge pipe 13 of liquid medicine storage tank, metering pump 14, outlet pipe 15 of metering pump, liquid medicine storage tank 16, solenoid valve B17, liquid medicine delivery pipe 18 , agitating nozzle 19, tightening screw nut 21, tightening washer 22, agitating nozzle inlet pipe 23, agitating nozzle outlet pipe 24, taper pipe thread 25, ordinary fine thread 26, upper suction pipe 3 nozzles and lower suction pipe 4 The nozzle is placed in the center of the dispensing tank 1, the upper suction pipe 3 and the lower suction pipe 4 are connected to the suction pipe 5 of the plastic pump, the suction pipe 5 of the plastic pump is connected to the inlet of t...

Embodiment 2

[0062] The double-port parallel pump circulation stirring dispensing process includes: dispensing tank 1, liquid level sensor 2, upper suction pipe 3, lower suction pipe 4, plastic pump suction pipe 5, workbench 6, emptying valve 7, emptying pipe 8, electromagnetic Valve A9, plastic pump 10, check valve 11, stirring pipe 12, liquid medicine storage tank outlet pipe 13, metering pump 14, metering pump outlet pipe 15, medicine liquid storage tank 16, solenoid valve B17, medicine liquid delivery pipe 18 , agitating nozzle 19, tightening screw nut 21, tightening washer 22, agitating nozzle inlet pipe 23, agitating nozzle outlet pipe 24, taper pipe thread 25, ordinary fine thread 26, upper suction pipe 3 nozzles and lower suction pipe 4 The nozzle is placed in the center of the dispensing tank 1, the upper suction pipe 3 and the lower suction pipe 4 are connected to the suction pipe 5 of the plastic pump, the suction pipe 5 of the plastic pump is connected to the inlet of the plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com