Low-consumption ore grinding method for ore for beneficiation

An ore and ore grinding technology, which is applied in the field of low-consumption grinding of ore for beneficiation, can solve the problems of difficult dehydration of mineral mud, high investment in equipment and workshops, incomplete mineral dissociation, etc., and achieves complete dissociation and high mineral Recovery rate, the effect of reducing project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

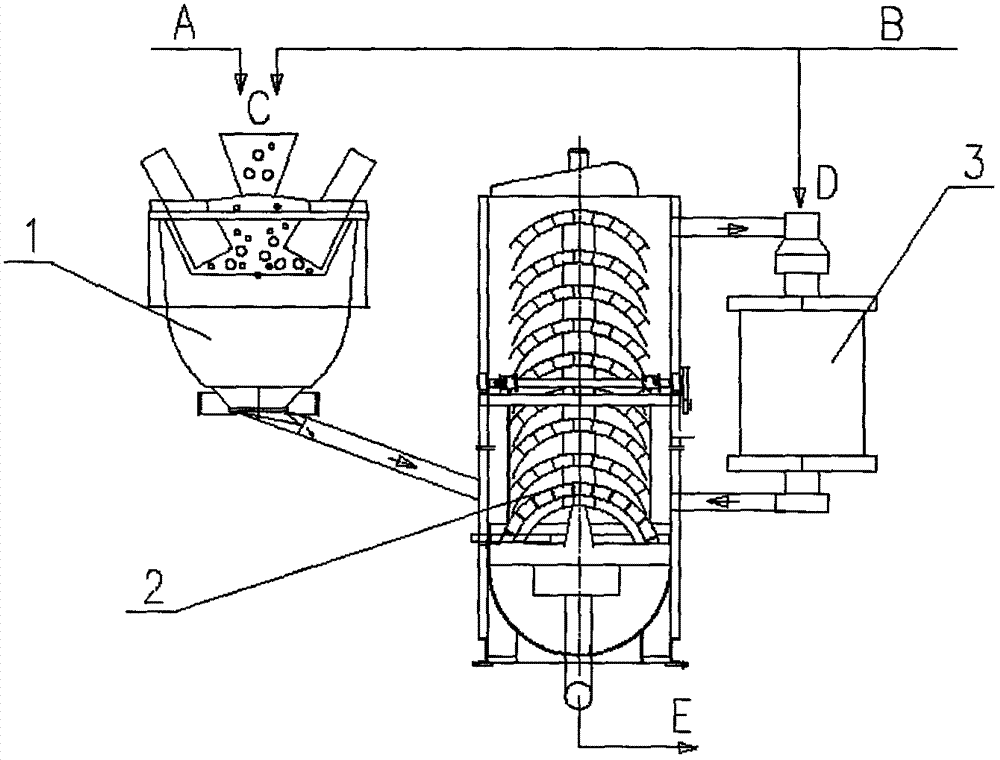

Embodiment 1

[0018] The Henan bauxite with an aluminum-silicon ratio of 3.5-4.0 and a large amount of slime is crushed to less than 25mm. After crushing, the ore is quantitatively transported into the wet roller mill 1 by a belt conveyor. The wet roller mill uses a vertical Mortar rotary mill, add water into the vertical mortar rotary mill, and the ore is ground into coarse pulp in the vertical mortar rotary mill. The particle size of the coarse pulp is +3mm30%. Classification equipment 2 classification, classification equipment 2 is a spiral classifier, the coarse ore particles classified by the spiral classifier enter the wet ball mill 3, add an appropriate amount of water to the wet ball mill 3 for further grinding, and the ground pulp returns to the classification equipment 2. The overflow of grading equipment 2 is discharged along the B direction as qualified pulp; the qualified pulp particle size is +0.074mm<15%, -0.038mm<55%, which is an ideal bauxite beneficiation pulp without muddy...

Embodiment 2

[0020] The Henan bauxite with an aluminum-silicon ratio of 2.0-2.5 and a large amount of slime is crushed to less than 25mm. After crushing, the ore is quantitatively transported into the wet roller mill 1 by a belt conveyor. The wet roller mill uses a vertical Mortar rotary mill, add water into the vertical mortar rotary mill, and the ore is ground into coarse pulp in the vertical mortar rotary mill. The particle size of the coarse pulp is +3mm40%. Classification equipment 2 classification, classification equipment 2 is a spiral classifier, the coarse ore particles classified by the spiral classifier enter the wet ball mill 3, add an appropriate amount of water to the wet ball mill 3 for further grinding, and the ground pulp returns to the classification equipment 2. The overflow of grading equipment 2 is discharged along the B direction as qualified pulp; the qualified pulp particle size is +0.074mm<15%, -0.038mm<60%, which is an ideal bauxite beneficiation pulp without muddy...

Embodiment 3

[0022]The Shanxi Yangquan bauxite with an aluminum-silicon ratio of 3.5-4.0 and no slime is crushed to less than 25mm. After crushing, the ore is quantitatively transported into the wet roller mill 1 by a belt conveyor. The wet roller press uses a vertical Rotary mortar mill, add water into the vertical rotary mortar mill, and the ore is ground into coarse pulp in the vertical rotary mortar mill. The particle size of coarse pulp is +3mm20%. Classification by grading equipment 2, grading equipment 2 is a spiral classifier, and the coarse ore particles classified by the spiral classifier enter the wet ball mill 3, and an appropriate amount of water is added to the wet ball mill 3 for further grinding, and the ground pulp returns to classification Equipment 2, the overflow of classification equipment 2 is discharged along the B direction as qualified pulp; the qualified pulp particle size is +0.074mm<15%, -0.038mm<45%, which is an ideal bauxite beneficiation pulp without muddy phe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com