High-speed train brake disc hub forging die and design method thereof

A technology of high-speed trains and design methods, applied in the field of forging, can solve problems such as waste, large machining allowance, and long machining cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

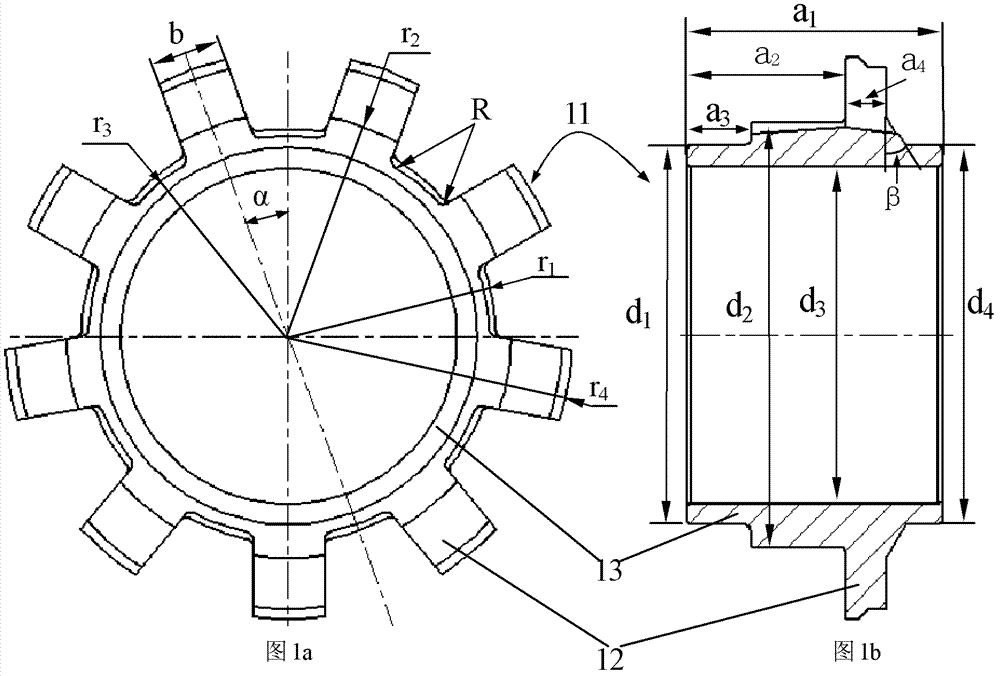

[0200] The forged part of this embodiment is a brake disc hub of a high-speed train from 200 km / h to 350 km / h. The material of the blank is 40CrA, the part weighs 18.218Kg, the heating temperature of the blank is 1200° C., and the material of the mold is 55CrNi. The machining allowance after forging is designed to be 5mm.

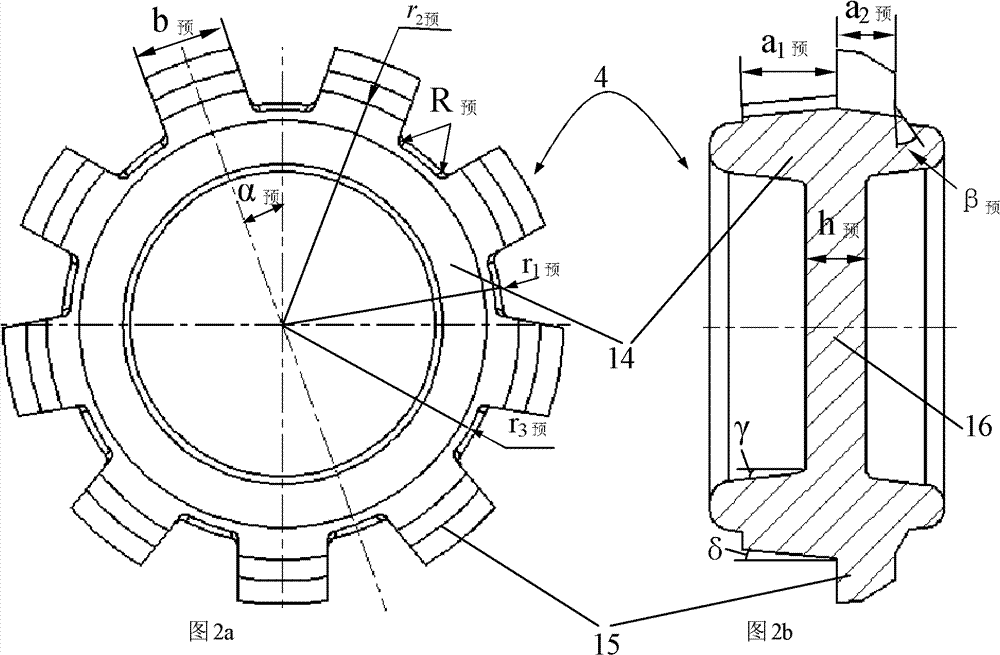

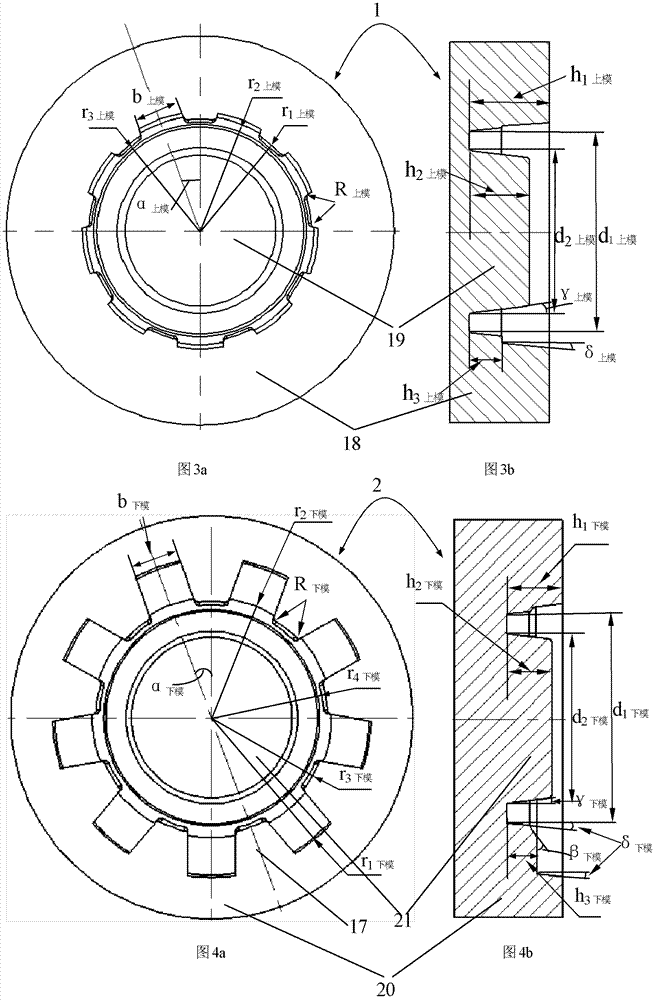

[0201] In this embodiment, the key parameters obtained by the Deform simulation software are: the optimized preform continuous skin thickness h 预 It is 32-40mm. Then, the main dimensions of the pre-forging upper die are obtained by combining the analytical method: the depth of the inner cavity of the V-shaped base of the pre-forging upper die is 93mm, the taper of the outer wall of the V-shaped base of the pre-forging upper die is 3°~5°, and the cone of the pre-forging upper die is The height of the boss is 64-80mm, and the taper of the conical boss of the pre-forging upper die is 5°-7°; the main dimensions of the pre-forging lower die are obtained through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com