Preparation method of silicon film

A technology of silicon film and silicon substrate, which is applied in the field of semiconductor device preparation, can solve the problems of different corrosion rates, the influence of silicon film uniformity, difficulty in obtaining uniform silicon film with precise thickness, etc., so as to control the degree of corrosion and ensure uniformity and the effect of thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further illustrate the present invention below in conjunction with accompanying drawing. Those skilled in the art can understand that the following only describes the gist of the present invention in conjunction with specific embodiments, and does not limit the implementation of the present invention to this example. The scope of the present invention is determined by the appended claims, and any modifications and changes that do not deviate from the spirit of the present invention shall be covered by the claims of the present invention.

[0018] In the following embodiments, the silicon substrate is single crystal silicon, and the prepared silicon film is described as a thin single crystal silicon film used in MEMS, for example, but it should be understood that this embodiment is illustrative rather than restrictive.

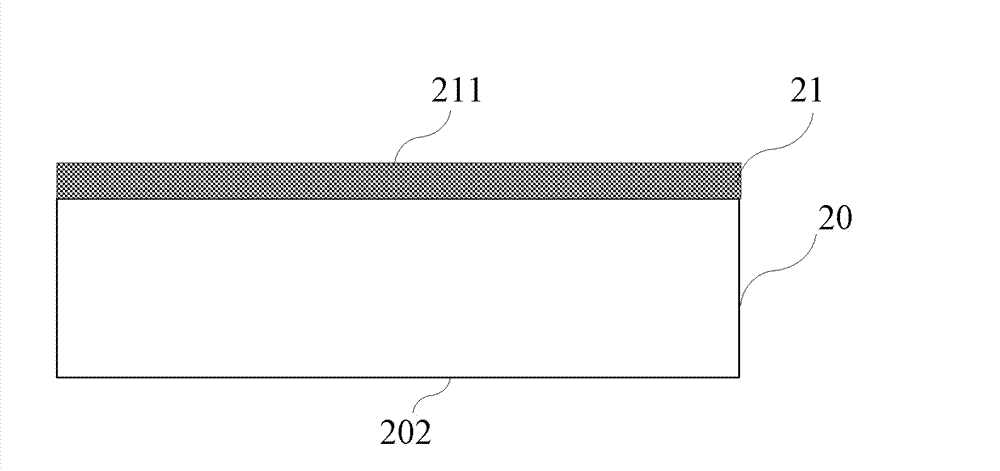

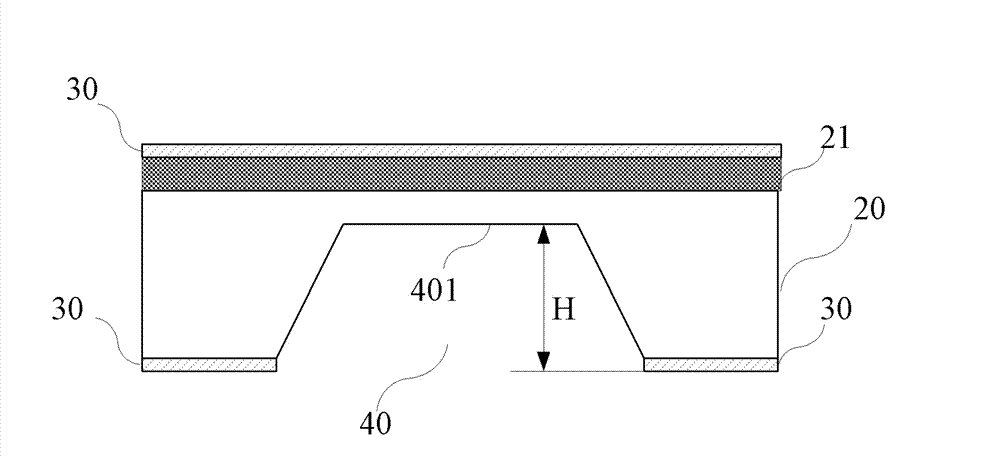

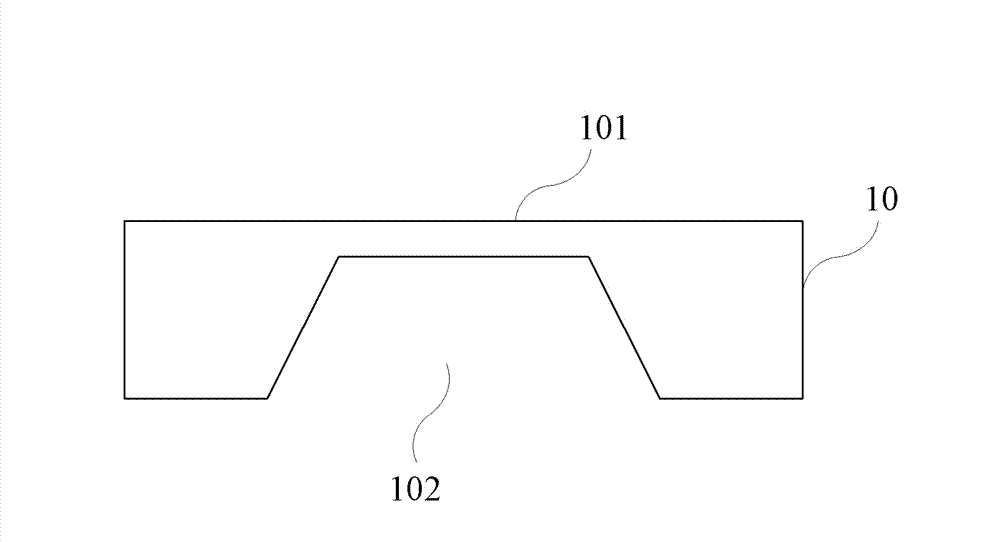

[0019] image 3 Shown is a heavily doped crystal silicon substrate 20 . The dopant in the single crystal silicon substrate 20 can be a conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com