Negative pressure type concrete wet-spray machine set

A concrete and negative pressure technology, which is applied in the field of negative pressure concrete wet spraying unit, can solve the problems of affecting the quality of the support, the inability to guarantee the quality of the concrete, and the lack of integration, so as to reduce the labor intensity of the workers, improve the working conditions of the workers, and operate Effects with ease of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

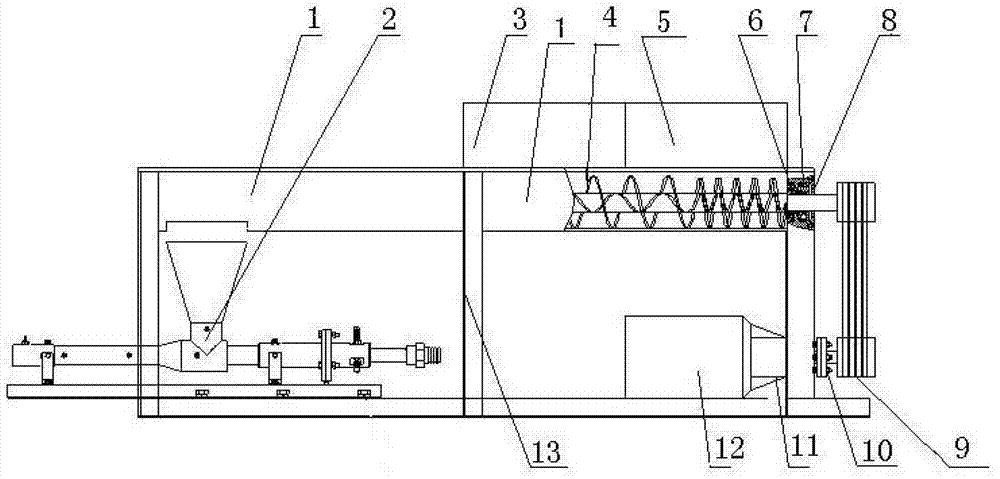

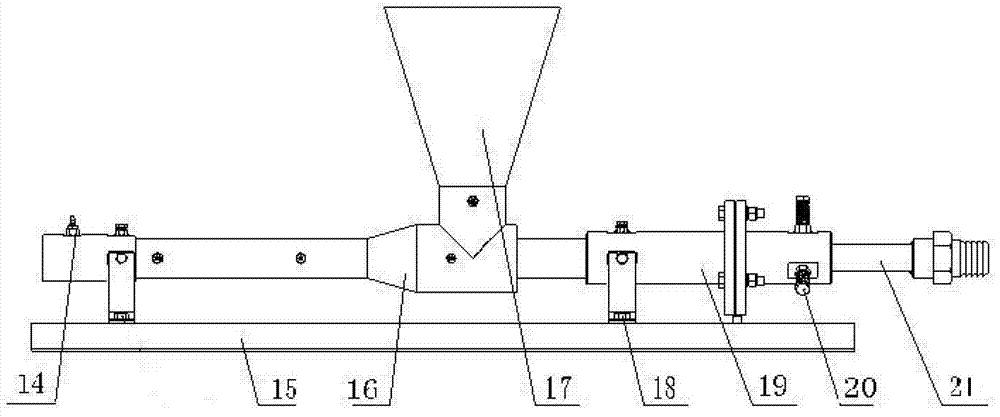

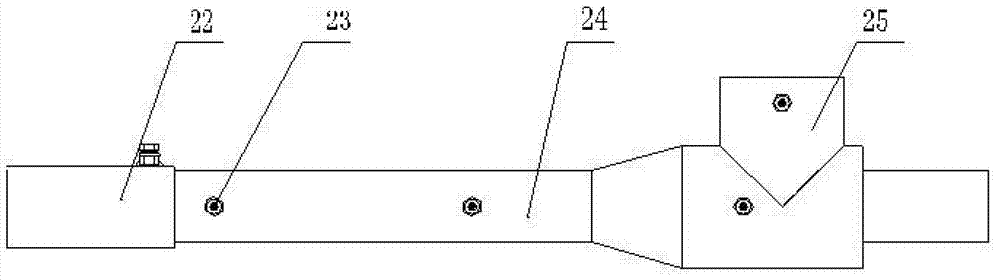

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as Figures 1 to 3 As shown, a negative pressure concrete wet spraying unit includes a pneumatic conveying injector 2, a frame 13, a base 15, and the pneumatic conveying injector is fixed on the base 15 of the frame 13, including a hopper 17, a support frame 18, a wind turbine The pipe seat 19, the pneumatic conveying injector also includes a Venturi tube 16, and the negative pressure concrete wet spraying unit also includes a spiral batching stirring device; the Venturi tube 16 is fixed on the support frame 18 on the base 15, and is welded through its rear end The short round pipe of the air pipe is connected with the air pipe seat 19, and is connected with the hopper 17 through the short round pipe whose rear end is perpendicular to the axial direction; 4. Cement hopper 5, bearing 7, and bearing cover 8. The driving mechanism includes a transmission mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com