Direct-current chopping power module

A power module and DC chopper technology, which is applied to conversion devices and instruments for converting DC power input into DC power output and output power. Falling off, affecting the life of the overall power device, etc., to increase the overall connection strength, improve work reliability, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

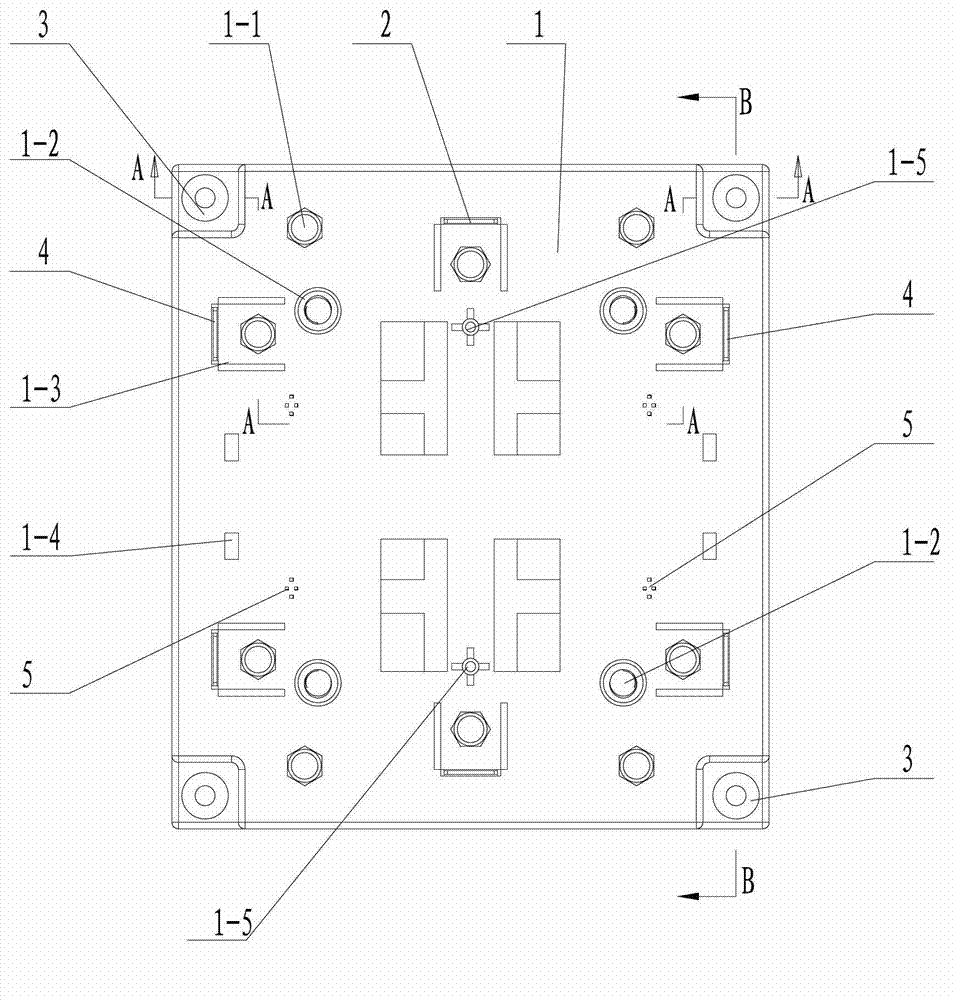

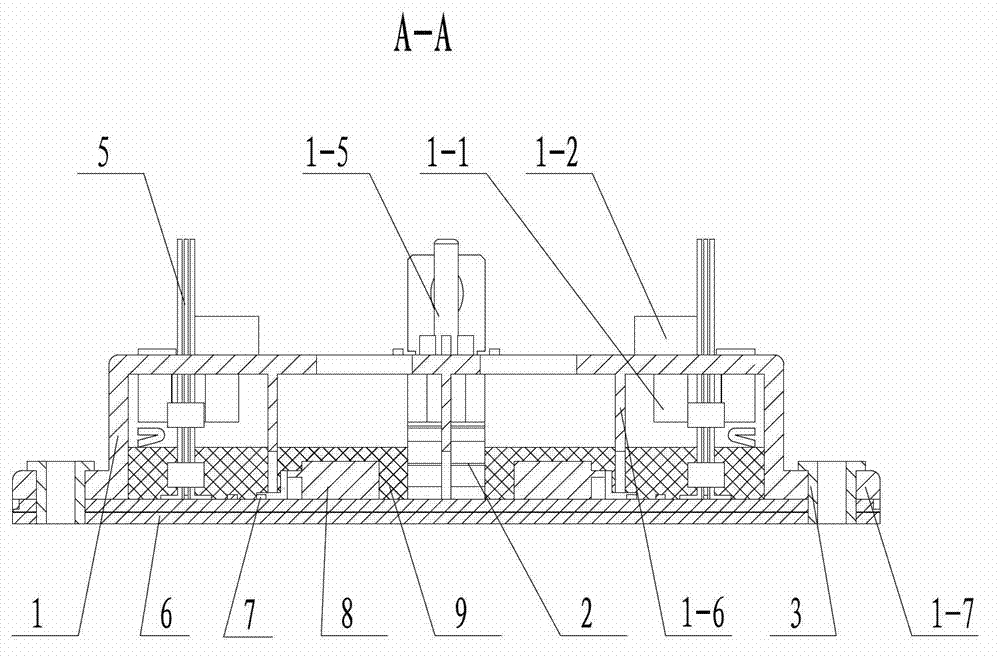

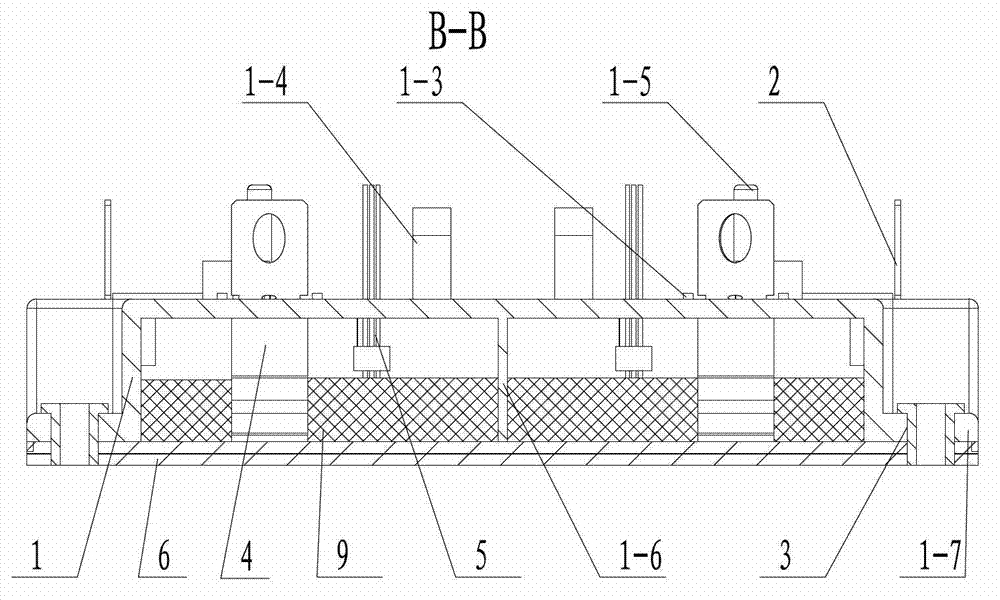

[0015] See Figure 1~4 As shown, the DC chopper power module of the present invention includes a casing 1 and a main circuit board, and the main circuit board includes a substrate 6 and a semiconductor chip 8 connected to the substrate 6, each device 7 and at least two electrode terminals 4 and control terminals 5. The substrate 6 of the present invention is composed of a metal-ceramic substrate and a copper base plate. Various devices 7 such as capacitors and diodes, as well as semiconductor chips 8, electrode terminals 4 and control terminals 5 are all welded on the substrate 6 to realize circuit connection and constitute as follows: Figure 7 In the shown DC chopper circuit, the bottom surface of the substrate 6 can be fixed on the radiator, and the heat produced by the DC chopper power module can be forcibly dissipated through the radiator. Fixed, the sealant can adopt silicone gel. In order to facilitate the connection and installation of the shell 1 and the base plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com