A loudspeaker based on injection molding process

A technology of injection molding and loudspeaker, applied in the field of loudspeakers, can solve the problems of difficulty in reducing the manufacturing cost of loudspeakers, low product yield, unstable quality, etc., and achieve the effects of simple manufacturing process, reduced manufacturing cost, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

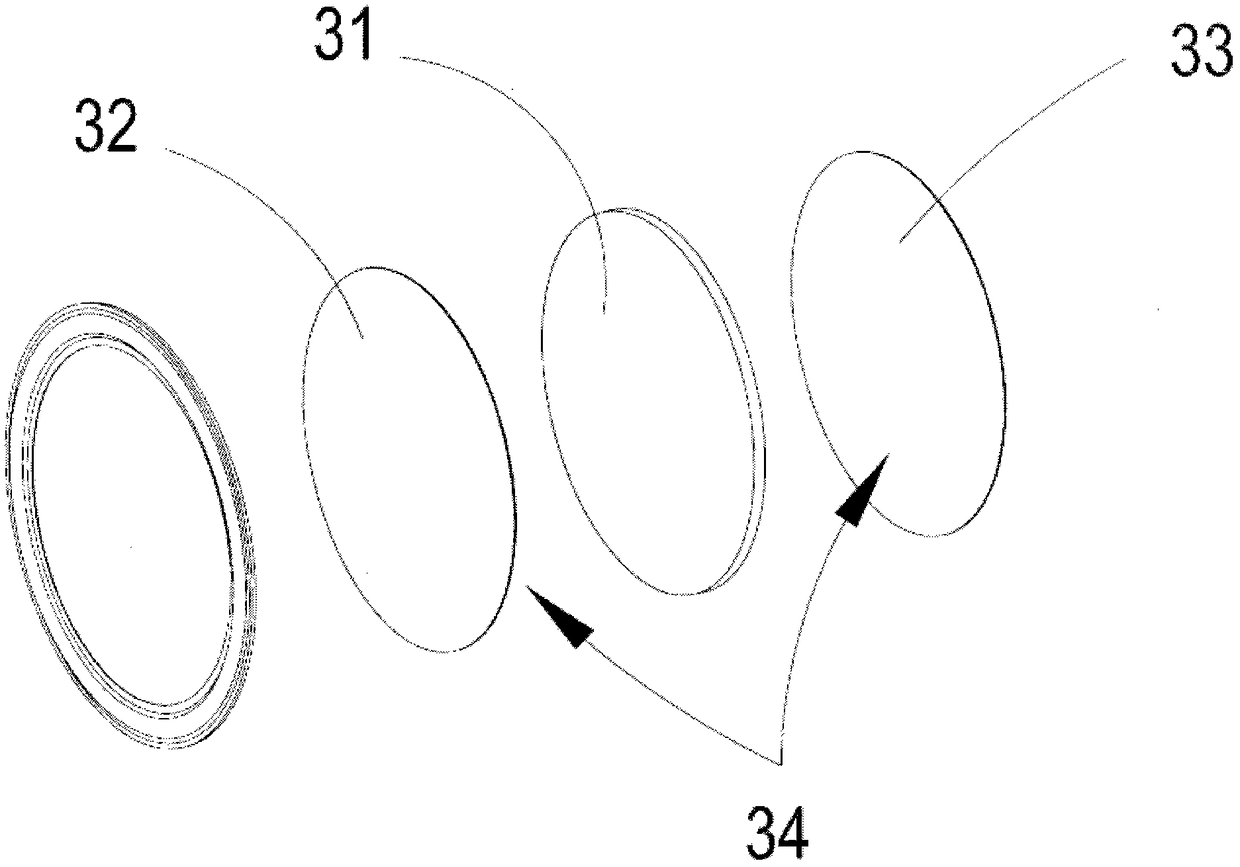

[0050] The loudspeaker of the present invention comprises an electroacoustic transducer 1, a supporting frame 2 placed thereon, and a drum paper 3 placed inside the top end of the supporting frame 2. The electro-acoustic transducer and the supporting frame 2 adopt common basic structures and elements in the prior art. The structure of the drum paper 3 is as above, except that the top cover layer 32 and the bottom cover layer 33 are made of kraft paper.

Embodiment 2

[0052] The loudspeaker of the present invention comprises an electroacoustic transducer 1, a supporting frame 2 placed thereon, and a drum paper 3 placed inside the top end of the supporting frame 2. The electro-acoustic transducer and the supporting frame 2 adopt common basic structures and elements in the prior art. The structure of the drum paper 3 is as above, except that the top cover layer 32 and the bottom cover layer 33 are made of aluminum metal sheet, titanium metal sheet or other suitable metal sheets.

Embodiment 3

[0054] The loudspeaker of the present invention comprises an electroacoustic transducer 1, a supporting frame 2 placed thereon, and a drum paper 3 placed inside the top end of the supporting frame 2. The electro-acoustic transducer and the supporting frame 2 adopt common basic structures and elements in the prior art. The structure of the drum paper 3 is as above, except that the top cover layer 32 and the bottom cover layer 33 are made of non-woven fabric, flat woven fabric or other suitable braided fabrics.

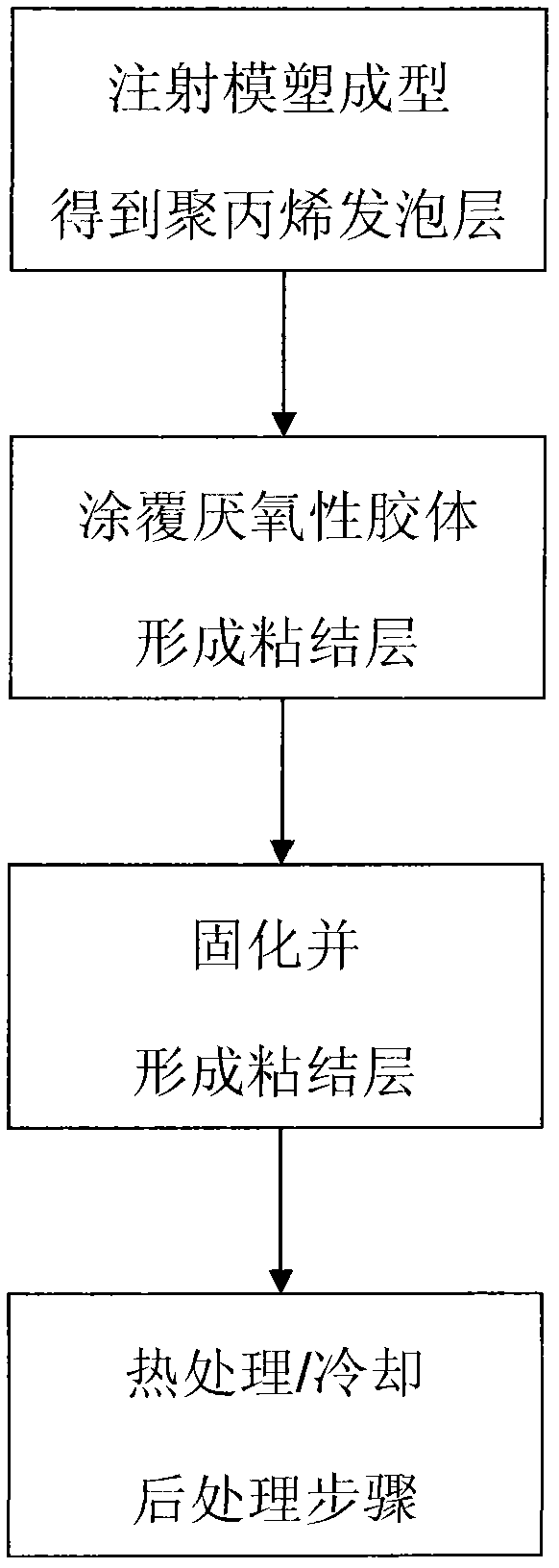

[0055] As mentioned above, the loudspeaker of the present invention adopts a kind of drum paper based on the injection molding process, and its inner interlayer is made of polypropylene foam material, and glue is applied on the upper and lower sides of the polypropylene foam material layer, because the inner interlayer is The foamed polypropylene material has a basically flat surface, even if there are fluctuations, but the range is not large, it is easy to apply glue, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com