Prefabricated pile end plate skirt ring processing equipment

A technology for processing equipment and end plates, which is applied in the field of prefabricated pile end plate skirt processing equipment, can solve the problems of low automation, low efficiency, and many manual participation, so as to reduce production costs, improve work efficiency, and work The effect of environmental improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

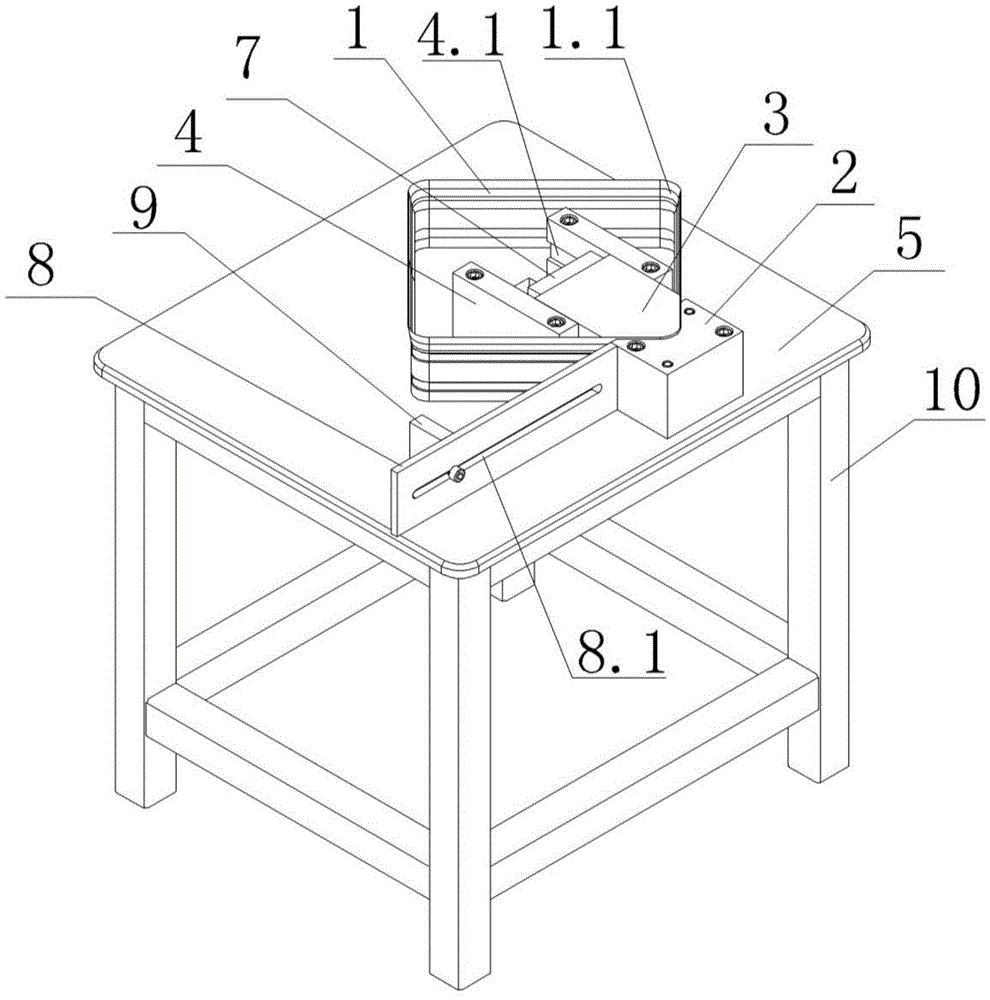

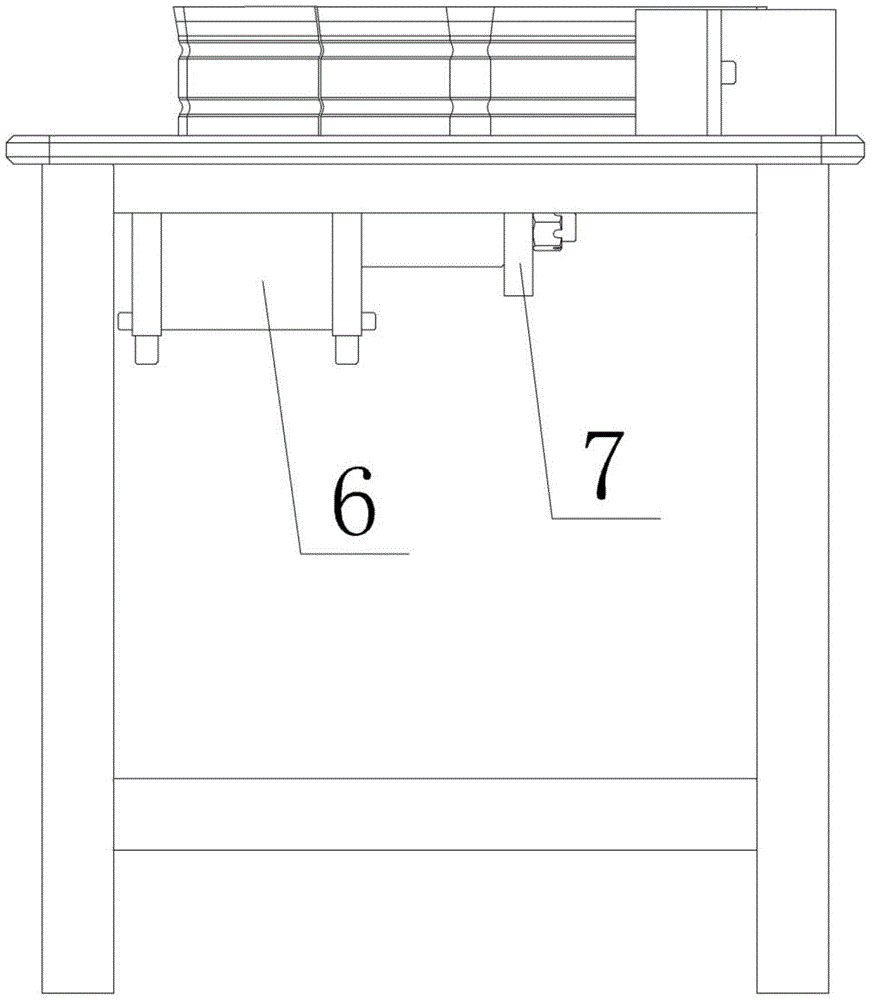

[0022] The prefabricated pile end plate skirt ring processing equipment of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] like figure 1 and figure 2 As shown, the prefabricated pile end plate skirt ring processing equipment of the present invention includes a workbench 5, and also includes a fixed die 2 and a movable punch 3 that are paired for forming the skirt ring 1 skirt angle 1.1, and the movable punch 3 The guiding structure 4 which acts as a guide for the movement of the movable punch 3 and the driving mechanism 6 which provides the power source for the movement of the movable punch 3 . Both the fixed die 2 and the guide structure 4 are installed on the workbench 5, and the workbench 5 is installed on a support frame 10 in this embodiment. The fixed die 2 is provided with a working surface (not shown) of the die that is the same as the skirt angle, skirt angle arc transition edge radian, and skirt angle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com