Method and device for removing moisture and solid impurities in investment casting mold material by pressure coalescence

An investment casting and solid impurity technology, which is applied to the cleaning/processing machinery of casting materials, casting molding equipment, manufacturing tools, etc. Low energy consumption, improve the quality of mold material, reduce the effect of oxidative deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

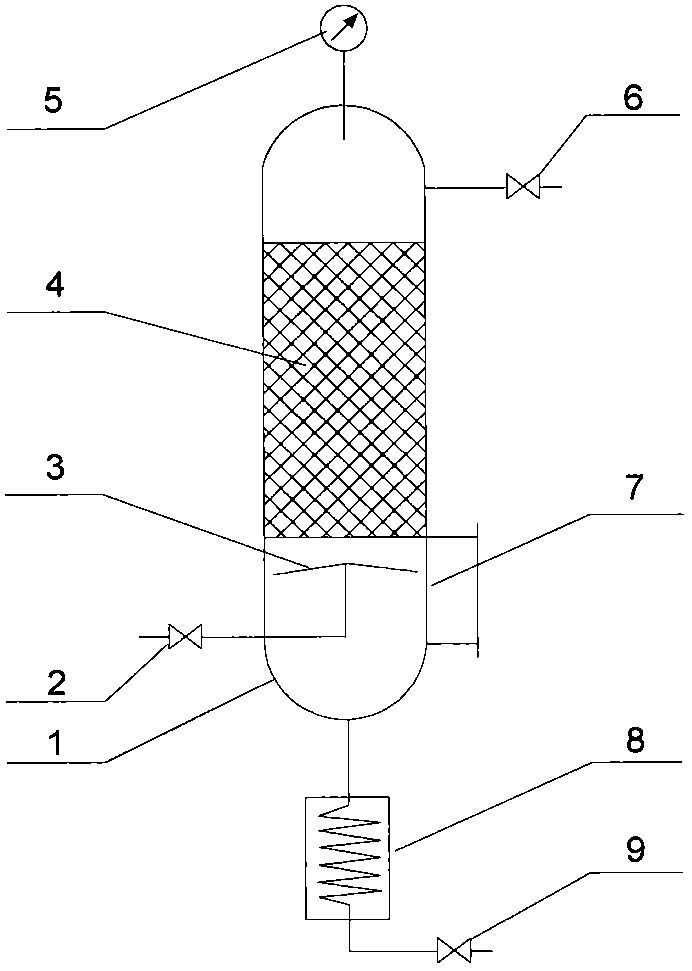

[0029] Such as figure 1 As shown, the vertical tank device for pressurized coalescence to remove moisture and solid impurities in the investment casting mold material includes a control system (not shown), a heat preservation tank 1, a feed control valve 2, and a liquid inlet distributor 3 , coalescing packing 4, pressure sensor 5, discharge control valve 6, window 7, separated water cooler 8, separated water discharge control valve 9; The liquid distributor 3, the liquid inlet distributor 3 is connected with the feed control valve 2 under the heat preservation tank 1; the top of the heat preservation tank 1 is connected with the discharge control valve 6, and is provided with a pressure sensor 5; the bottom of the heat preservation tank 1 is separated from the The water cooler 8 is connected, and the outlet of the separated water cooler 8 is provided with a discharge control valve 9 for slag-containing separated water; an observation window 7 is provided at the wax-water inte...

Embodiment 2

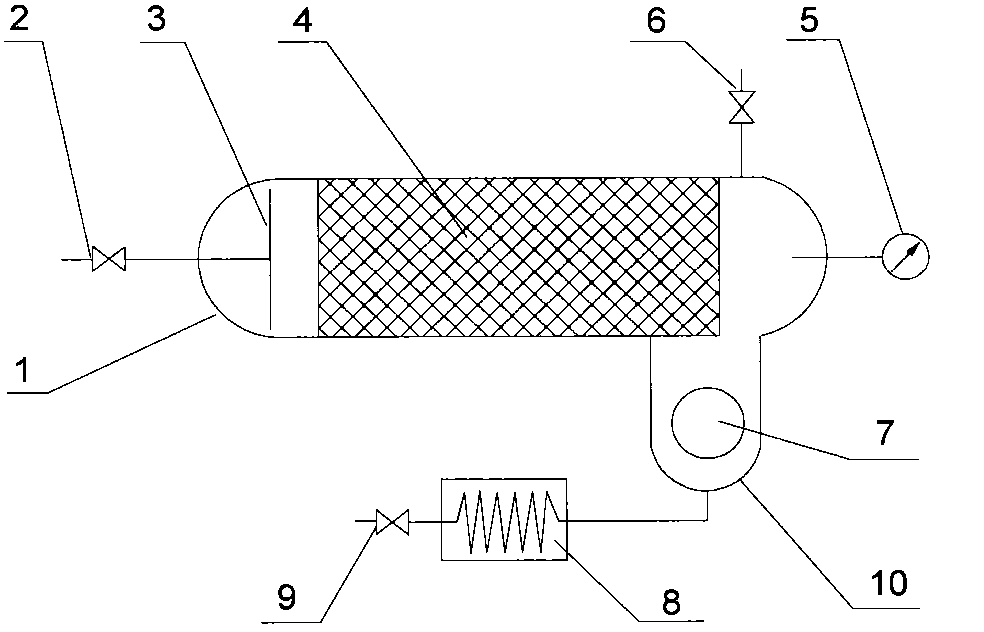

[0035] Such as figure 2 As shown, the horizontal tank device for pressurized coalescence to remove moisture and solid impurities in the investment casting mold material includes a control system (not shown), a heat preservation tank 1, a feed control valve 2, and a liquid inlet distributor 3 , coalescing filler 4, pressure sensor 5, discharge control valve 6, window 7, separated water cooler 8, separated water discharge control valve 9, water bag 10; one end of the insulation tank 1 is connected with the feed control valve 2, and the other One end is connected to the discharge control valve 6 from the top, and a pressure sensor 5 is provided to measure the pressure in the insulation tank 1; the feed control valve 2 is connected to the liquid inlet distributor 3 in the insulation tank 1; the coalescing filler 4 is filled in the insulation tank 1 The middle area in the tank 1; the bottom of the insulation tank 1 is provided with a water bag 10, and the water bag 10 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com