Efficient cutting device of ball-end milling cutter

A technology of ball end milling cutter and transmission device, which is applied to milling machine equipment, details of milling machine equipment, metal processing equipment, etc., and can solve problems such as easy wear and chipping of the center of the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

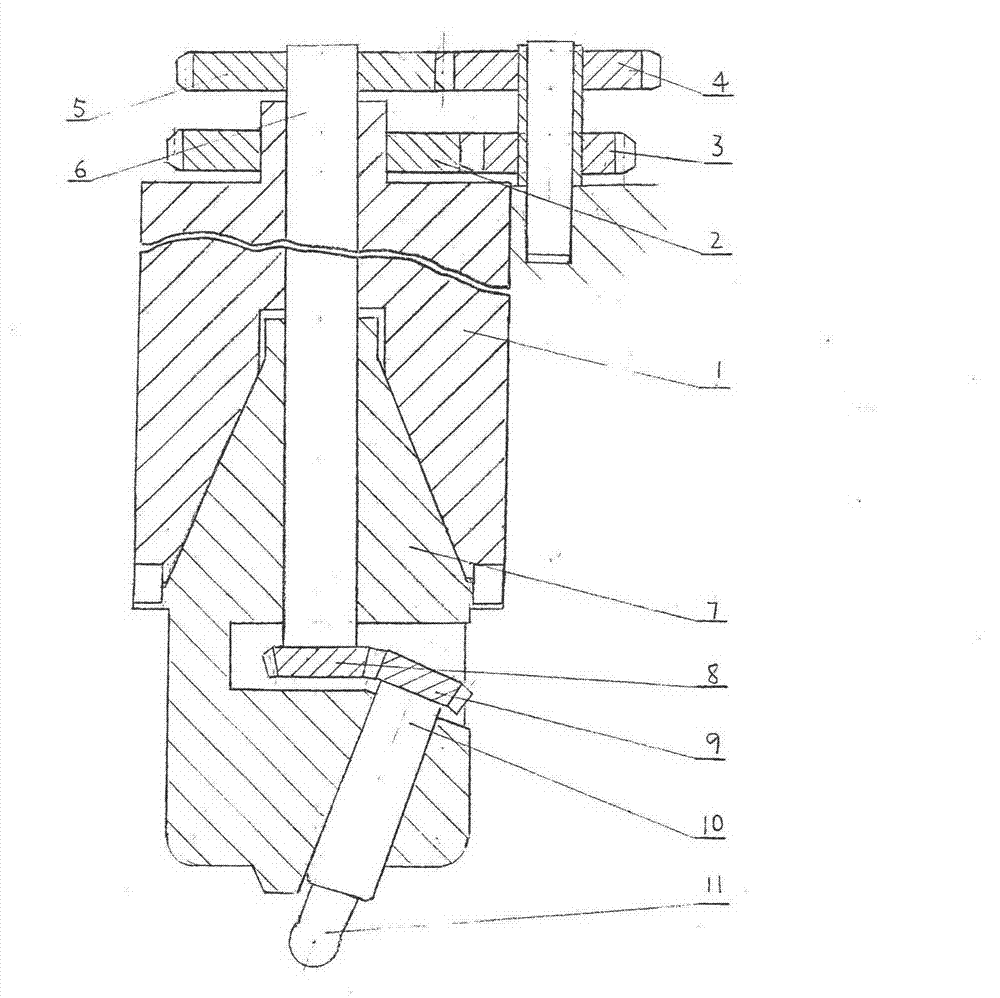

[0014] Such as figure 1 As shown, the main shaft 1 rotates to drive the gear 2, the gear 2 drives the double gears 3, 4, the gear 4 drives the intermediate shaft 6 through the gear 5, the intermediate shaft 6 drives the driven shaft 10 through a pair of bevel gears 8, 9, and the driven shaft 10 Make the cutter 11 rotate. The connecting body 7 (the connecting body is not required for a special device) makes the driven shaft rotate around the main shaft while rotating on its own.

Embodiment 2

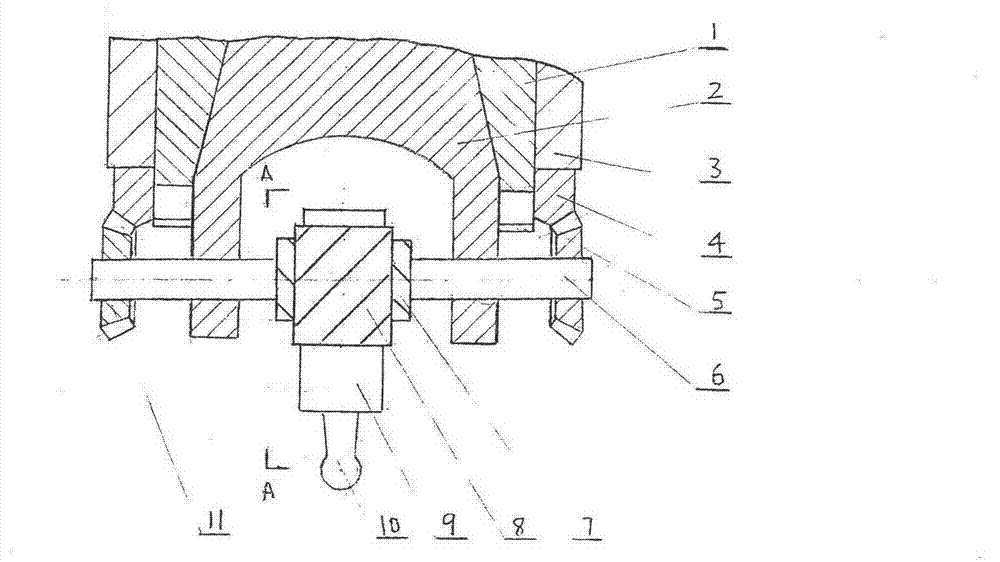

[0016] Such as figure 2 As shown, the main shaft 1 drives the connecting body 2, and the connecting body 2 makes the transverse shaft 6 rotate, and drives the bevel gear 5 to rotate around the center of the main shaft, and the bevel gear ring gear 4 meshing with it is installed on the sleeve 3 (or on the fuselage) , is non-rotating, so the bevel gear 5 rotates at the same time, and the transverse shaft 6 rotates through a pair of 45 helical gears 7, 8 to drive the driven shaft 9, and the driven shaft 9 makes the cutter 10 rotate. Bevel gear 11 only plays a balancing role. The characteristic of this structure is that the angle of the driven shaft can be adjusted.

Embodiment 3

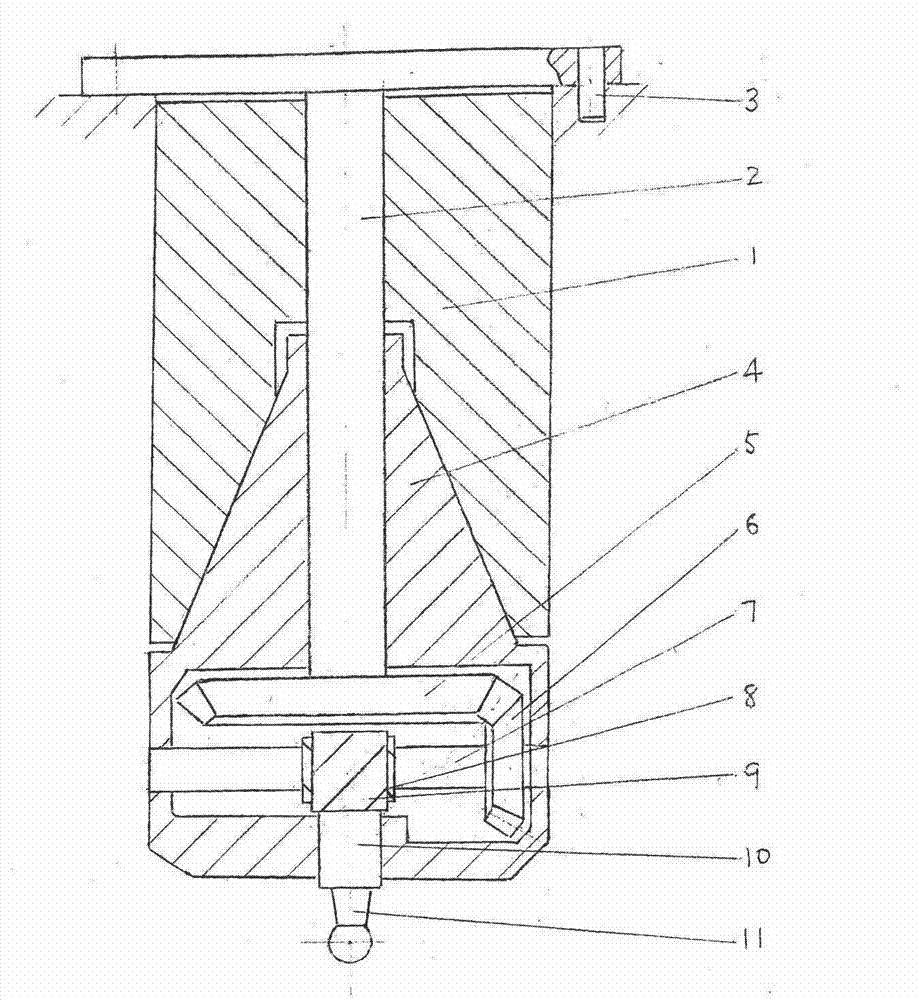

[0018] Such as image 3 As shown, the intermediate shaft 2 is fixed on the upper end of the end milling head by the pin 3 and does not rotate; the bevel gear 5 is installed on the intermediate shaft and does not rotate. When the main shaft 1 rotates, the connecting body 4 rotates together, and the bevel gear 6 meshing with the bevel gear ring gear 5 rotates around the center and rotates on its own. The bevel gear 6 drives the horizontal axis to rotate, and the horizontal axis makes the driven shaft and the center rotate at an included angle through a pair of helical gears, and rotate by itself; the included angle can be adjusted. The driven shaft rotates the tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com