Ultra heat treated (UHT) liquid milk packaging film of multilayer plastic composite structure and preparation method thereof

A composite structure, liquid milk technology, applied in packaging, wrapping paper, packaged food, etc., can solve problems such as plastic smell and other peculiar smells, and achieve the effects of reducing peculiar smell, maintaining flavor and taste, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

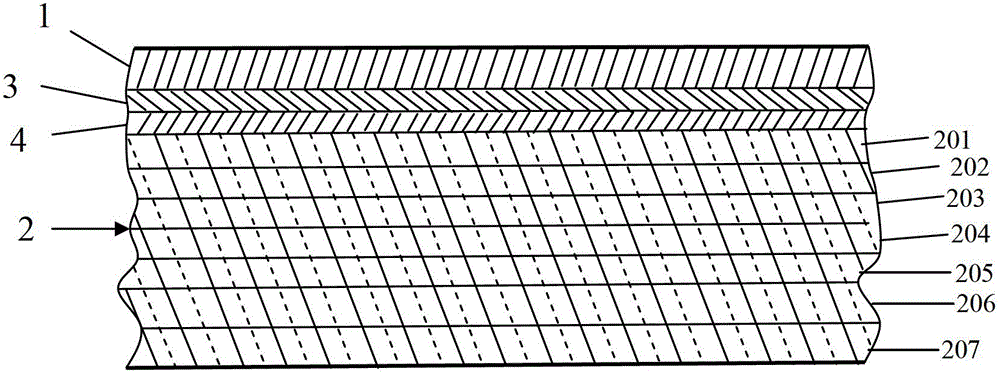

[0045] Such as figure 1 As shown, the UHT liquid milk packaging film of multi-layer plastic composite structure in this embodiment includes a co-extruded off-white film layer 2, and the co-extruded off-white film layer 2 sequentially includes a first color-developing layer 201, a second color-developing layer 202, The first adhesive layer 203 , the fresh-keeping barrier layer 204 , the second adhesive layer 205 , the light-shielding layer 206 , and the heat-sealing layer 207 .

[0046] The UHT liquid milk packaging film of this embodiment further includes a printed film layer 1 , a printed ink layer 3 and a third adhesive layer 4 in sequence.

[0047] The printing ink layer 3 and the third adhesive layer 4 are located between the printing film layer 1 and the first color-developing layer 201 of the co-extruded off-white film layer 2, the third adhesive layer 4 and the co-extruded off-white film Layers of the first color-developing layer 201 are connected. The printing ink la...

Embodiment 2

[0064] The UHT liquid milk packaging film of the multilayer plastic composite structure in the present embodiment co-extrudes the off-white film layer 2 and embodiment 1, and its difference is:

[0065] The material of the third adhesive layer 4 is low density polyethylene (LDPE) resin.

[0066] Correspondingly, the compounding in the step (3) of the specific manufacturing method is that the printed film layer 1 is extruded and compounded with the co-extruded gray-white film layer 2 through the third adhesive layer 4 .

[0067] In this embodiment, the thickness of the printing film layer 1 is 20 μm. The thickness of the co-extruded gray-white film layer 2 is 70 μm.

Embodiment 3

[0069] The difference between this embodiment and Embodiment 2 is that the thickness of the printed film layer in this embodiment is 25 μm. The thickness of the co-extruded gray-white film layer is 80 μm. The thickness of the fresh-keeping barrier layer is 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com