Method for preparing silicon oxide nanotube and two-dimensional ordered assembly body thereof

A technology for nanotubes and silicon oxide, applied in the field of preparing silicon oxide nanotubes and their two-dimensional ordered assemblies, can solve the problems of complex preparation process, high cost, uneven size of silicon oxide nanotubes, etc. Effects of controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

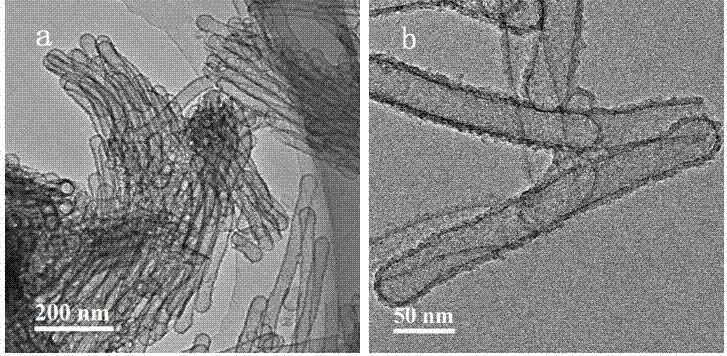

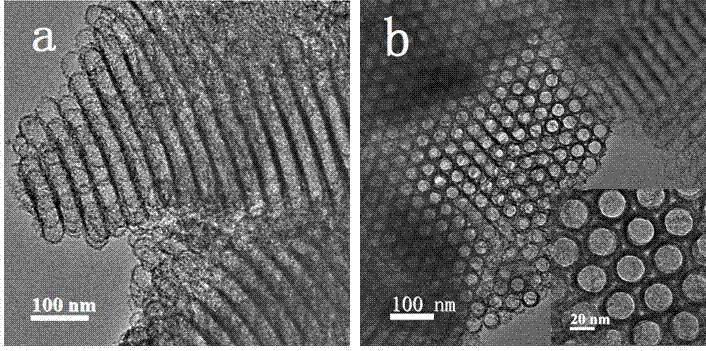

[0020] Example 1: 30 mg PEO- b -PS was dissolved in 8 g tetrahydrofuran, and 1.5 g 2 M HCl aqueous solution was added to obtain a clear and transparent solution. Stir and volatilize overnight (12 h) at room temperature at about 5°C; add 0.30 g ethyl orthosilicate to the above solution , keep stirring (rotating at 100 rpm) to volatilize (if preparing a two-dimensional ordered assembly of silicon oxide nanotubes, add 20 mg 1,2 -bis(triethoxysilyl)ethylene), until a large amount of white precipitate appeared at the end; washed with water and collected by centrifugation, dried at 15°C; then dispersed in 2 M HCl aqueous solution, heated at 100°C for 24 h; collected water The hot product was dried at 15°C; the resulting white solid was calcined in a muffle furnace at 550°C for 5 h.

Embodiment 2

[0021] Example 2: 30 mg PEO- b -PS was dissolved in 10 g tetrahydrofuran, and 2 g 2 M HCl aqueous solution was added to obtain a clear and transparent solution, which was stirred and volatilized at room temperature at about 10 °C overnight (8 h); 0.30 g methyl orthosilicate was added to the above solution , keep stirring (200 rpm) to volatilize (if preparing a two-dimensional ordered assembly of silicon oxide nanotubes, add 50 mg of orthosilicate 4 h after adding 1,2 -bis(triethoxysilyl)ethane), until a large amount of white precipitate appeared at the end; washed with water and collected by centrifugation, dried at 25°C; redispersed in 2 M HCl aqueous solution, heated at 120°C for 20 h; collected The hydrothermal product was dried at 25 °C; the obtained white solid was calcined in a muffle furnace at 500 °C for 6 h.

Embodiment 3

[0022] Example 3: 30 mg PEO- b -PS was dissolved in 10 g tetrahydrofuran, and 1.5 g 2 M HCl aqueous solution was added to obtain a clear and transparent solution, which was stirred and volatilized overnight (10 h) at a room temperature of about 10 °C; 0.30 g tetraethyl orthosilicate was added to the above solution , keep stirring (rotating at 200 rpm) for volatilization (if preparing a two-dimensional ordered assembly of silica nanotubes, add 30 mg of diethyldiethoxysilane 3 h after adding methyl orthosilicate) , until a large amount of white precipitate appeared at the end; washed with water and collected by centrifugation, dried at 20 °C; then dispersed in 2 M HCl aqueous solution, heated at 80 °C for 30 h; collected hydrothermal products, dried at 20 °C; The white solid is dispersed in excess sodium hydroxide solution, heated to 80-100°C and refluxed to remove the template agent; the obtained solid is collected by centrifugation, washed with water and then dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com