Sewage recycling processor

A processor and sewage technology, applied in the field of water treatment, can solve the problems of difficulty in achieving the quality of the effluent in one step, the exhaust gas needs to be further treated, and the energy consumption in the transfer process is large, so as to achieve good gas-water mass transfer effect, good effluent quality, and save The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

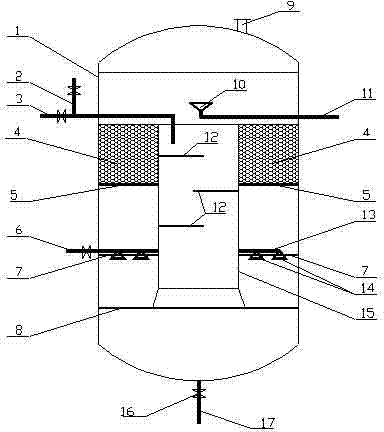

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] see figure 1 , an embodiment of a sewage reuse processor of the present invention, the shell 1 is made of a stainless steel plate of a certain thickness into a circular cylinder, the upper and lower ends are semi-elliptical heads, and are supported by the base. A central cylinder 15 is arranged in the middle of the housing 1, and a folded plate 12 is arranged inside the central cylinder 15. The folded plates described by the folded plate 12 are arranged up and down, and the first folded plate 12 on the top is arranged below the water inlet pipe. The second folded plates 12 are staggered and arranged downwards successively to form a baffle structure. There are three folded plates 12 in this example. The central cylinder 15 is seated on the support frame 8 . The upper end of the central cylinder 15 is closed, and the lower end is a trumpet-shaped opening that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com