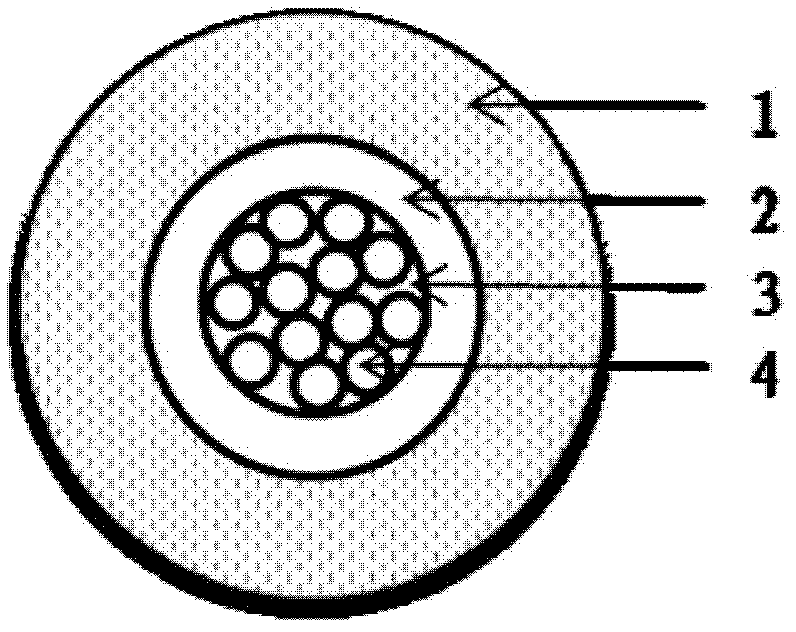

Double-coating spherical fertilizer and its preparation method

A double-coated, spherical technology, applied in fertilizer forms, fertilizer mixtures, fertilization devices, etc., can solve the problems of affecting the efficiency and effect of fertilization, high production and use costs, inability to spread far and spread evenly, etc. The effect of less pollution, saving usage, and reducing the chance of fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Double-coated spherical fertilizer and preparation method thereof:

[0026] 1. Fertilizer core: the fertilizer core is raised as a compound fertilizer (16-16-16, 48%), weighed 0.6 kg, and bonded it into a ball by a starch-based binder.

[0027] The preparation of described binding agent is:

[0028] 1) Add 500ml of water into the reaction vessel and heat it up to 50°C.

[0029] 2) Add 100 g of wheat starch into the reactor, stir evenly, and then add 40 ml of hydrogen peroxide (purity is 30%) therein.

[0030] 3) Rapidly increase the temperature of the reactants in the reactor to make the temperature of the liquid in the reactor reach 65° C., dissolve 80 g of potassium hydroxide in 140 ml of water, and slowly add the potassium hydroxide solution while stirring the liquid in the reactor.

[0031] 4) Take 5g of sodium tetraborate, dissolve it in 60ml of water, slowly add it into the reactor liquid, and react for 10 minutes.

Embodiment 2

[0038] Double-coated spherical fertilizer and preparation method thereof:

[0039]1. Fertilizer core: The fertilizer core is compound fertilizer (16-16-16, 48%), weighed 1.2 kg, and bonded it into a ball with a starch-based binder.

[0040] The preparation of described binding agent is:

[0041] 1) Add 500ml of water into the reaction vessel and heat it up to 50°C.

[0042] 2) Add 100 g of wheat starch into the reactor, stir evenly, and then add 40 ml of hydrogen peroxide (purity is 30%) therein.

[0043] 3) Rapidly increase the temperature of the reactants in the reactor to make the temperature of the liquid in the reactor reach 65° C., dissolve 80 g of potassium hydroxide in 140 ml of water, and slowly add the potassium hydroxide solution while stirring the liquid in the reactor.

[0044] 4) Take 5g of sodium tetraborate, dissolve it in 60ml of water, slowly add it into the reactor liquid, and react for 10 minutes.

Embodiment 3

[0050] 1. Fertilizer core: The fertilizer core is compound fertilizer (16-16-16, 48%), weighed 1.8 kg, and bonded it into a ball with a starch-based binder.

[0051] The preparation of described binding agent is:

[0052] 1) Add 500ml of water into the reaction vessel and heat it up to 50°C.

[0053] 2) Add 100 g of wheat starch into the reactor, stir evenly, and then add 40 ml of hydrogen peroxide (purity is 30%) therein.

[0054] 3) Rapidly increase the temperature of the reactants in the reactor to make the temperature of the liquid in the reactor reach 65° C., dissolve 80 g of potassium hydroxide in 140 ml of water, and slowly add the potassium hydroxide solution while stirring the liquid in the reactor.

[0055] 4) Take 5g of sodium tetraborate, dissolve it in 60ml of water, slowly add it into the reactor liquid, and react for 10 minutes.

[0056] 5) Take 10g of anhydrous calcium chloride, dissolve it in 60ml of water, then slowly add the calcium chloride solution into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com