LED (light emitting diode) lane light employing installation interface bracket combination component

A technology for installing interfaces and assembling components, which is applied to components of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc., and can solve problems such as inconvenient use, few batches, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

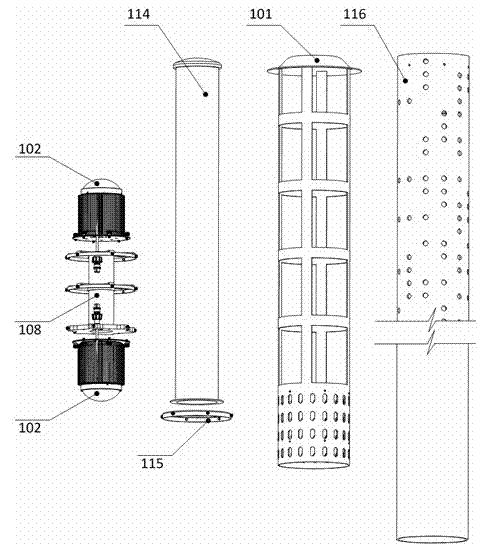

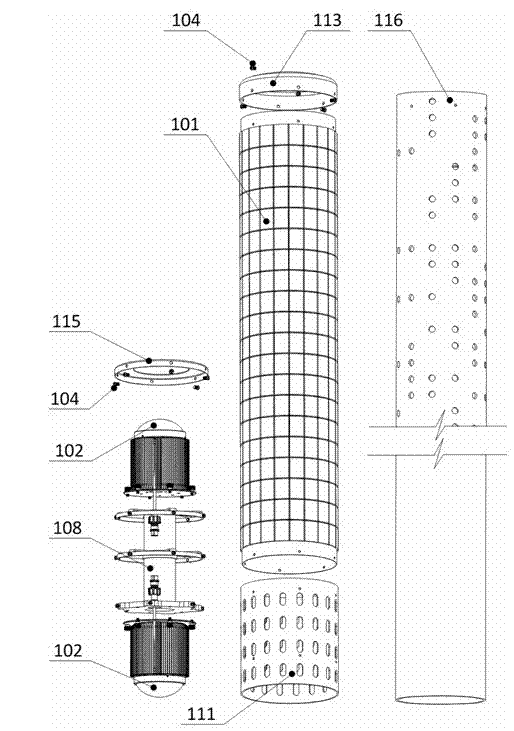

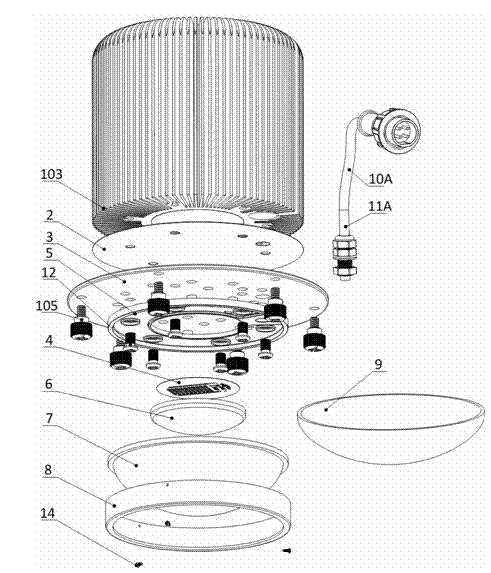

[0070] Example 1. The LED street lamp adopts the mounting interface bracket combination component, including the installation interface bracket combination component, the installation interface bracket combination component is equipped with an LED bulb 102 with its own radiator, and the installation interface bracket combination component is provided with metal stamping or plastic die casting. The mounting interface bracket assembly component is installed on the light pole 116; the mounting interface bracket assembly component includes a tube bracket 108, a lamp shade and bulb fixing bracket 110, and a lamp fixing bracket 109 that are connected to each other and are cut into sections from standard pipes. ; The lampshade and bulb fixing bracket 110 is provided with an A installation interface for installing the LED bulb 102; the lamp fixing bracket 109 is provided with a B installation interface for installing the LED bulb 102, and the tube bracket 108 connects the lamp fixing b...

Embodiment 2

[0075] Example 2. LED street lights using mounting interface bracket assembly components, such as figure 1 , Figure 25 , Figure 26 with Figure 30 As shown, it includes the mounting interface bracket assembly component. The mounting interface bracket assembly component is equipped with two LED bulbs 102 with its own heat sink. The mounting interface bracket assembly component is equipped with a metal stamping or plastic die-casting lampshade assembly. The installation interface The bracket assembly component is installed on the light pole 116; the installation interface bracket assembly component includes a tube bracket 108, a lamp shade and a bulb fixing bracket 110, and a lamp fixing bracket 109 that are connected to each other, which are cut from standard pipe sections; a lamp shade and a bulb fixing bracket 110 is provided with an A installation interface for installing the LED bulb 102; the lamp fixing bracket 109 is provided with a B installation interface for installin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com