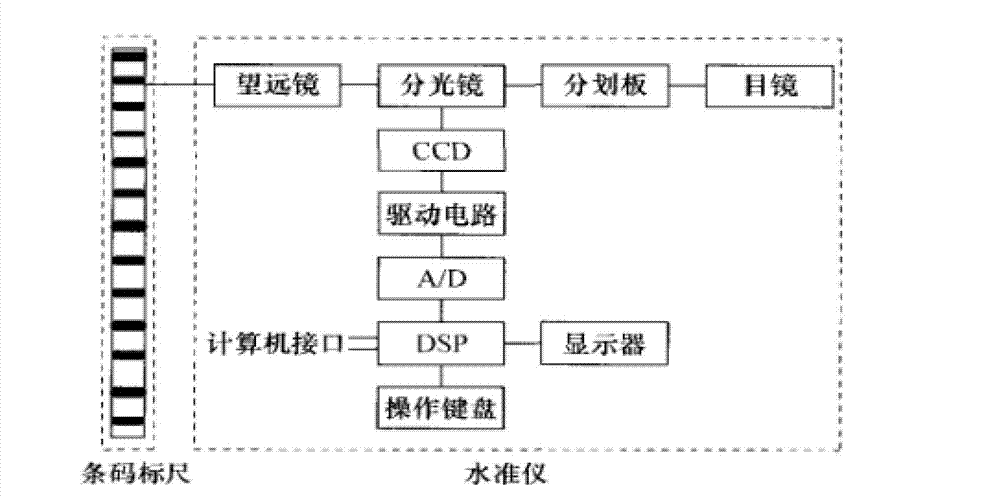

Digital levelling system, method, composite coding levelling staff and production method thereof

A technology of leveling ruler and composite coding, applied in the science and field of surveying and mapping, can solve the problem of excessive production process requirements, and achieve the effects of reducing costs, simplifying production processes, and reducing production accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

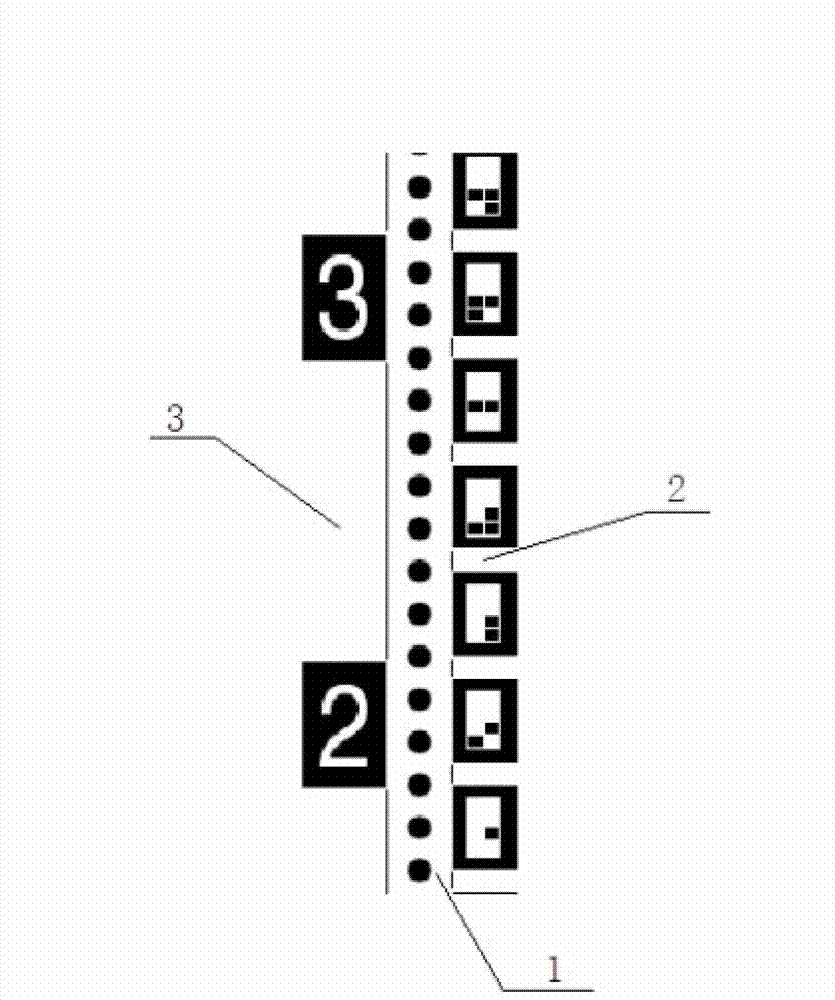

[0037] 1. Composite coding level gauge

[0038] The scale surface of the composite coded leveling rod is provided with a fine code area and a reading area in the horizontal direction. In the vertical direction of the fine code area, there are marking circles arranged in a single row at equal intervals and the same size. The distance between each marking circle and the bottom surface of the scale can be passed The reading area corresponding to the setting is calculated.

[0039] The reading area can include a digital label area, a rough code area, or a digital label area and a rough code area. In the rough code area, there are code blocks with equal intervals and the same size arranged in a single row in the vertical direction, and each code block is equally divided. It is M×N rectangular grids, where M and N are positive integers. Each rectangular grid in the coding block is filled with different colors to represent 0 and 1 for binary coding. There are marking boxes for coding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com