Interlaminar shear device of cylindrical test piece of bituminous paving and shearing method thereof

A technology of interlayer shearing and asphalt pavement, which is applied to measuring devices, using stable shearing force to test the strength of materials, instruments, etc., can solve the problems of easily damaged instruments, and cannot apply compressive stress on shearing surfaces, so as to avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

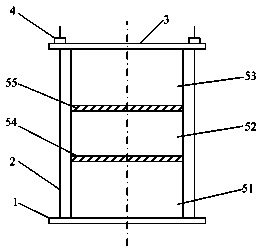

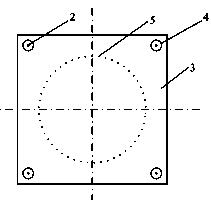

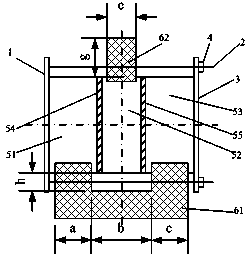

[0033] In this embodiment, the cylindrical specimen is manufactured layer by layer using the indoor rotary compaction method.

[0034] According to "T0736-2011 Asphalt Mixture Rotary Compaction Cylinder Test Specimen Manufacturing Method (SGC Method)" in "Highway Engineering Asphalt and Asphalt Mixture Test Regulations" (JTG E20-2011), the cylinder required by the present invention is produced in layers body test piece. Select a test mold with an inner diameter of 10cm and a length of 30cm; at the bottom of the test mold, make a first structural layer 51 with a thickness of 10cm by rotating and compacting the AC-25C type asphalt mixture; when the temperature of the first structural layer 51 drops to room temperature , modify the emulsified asphalt on the surface of the first structural layer 51, and apply a thickness of 0.3mm. After the emulsified asphalt breaks, the first adhesive layer 54 is formed; then, continue to fill the first adhesive layer 54 with AC-20C type For asp...

Embodiment 2

[0047] The present embodiment is all identical with embodiment 1 except subordinate feature:

[0048] In this embodiment, pavement core samples taken on-site are used.

[0049] The upper layer of the asphalt pavement of an expressway is SMA-13 asphalt mixture with a thickness of 4cm; the middle surface layer is AC-20C asphalt mixture with a thickness of 6cm; the lower layer is AC-25C asphalt mixture with a thickness of 8cm; The bonding layer between the upper and middle surface layers is 0.4mm thick modified emulsified asphalt; the bonding layer between the middle and lower layers is 0.5mm thick modified emulsified asphalt.

[0050] After 3 days of pavement construction, use a coring machine to drill continuous and complete core samples of the asphalt pavement upper layer, bonding layer, middle surface layer, bonding layer, and lower layer with a diameter of 10 cm for the shear test of the present invention. Wherein, the lower layer is the first structural layer of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com