Modeling method of soft measuring instrument for magnetic chain of bearingless asynchronous motor

A technology of asynchronous motor and modeling method, which is applied in the direction of instruments, electrical digital data processing, special data processing applications, etc., can solve the problems of difficult real-time measurement of flux linkage, etc., and achieve the effect of low cost, simple model, and easy engineering realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

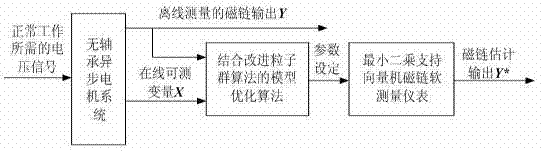

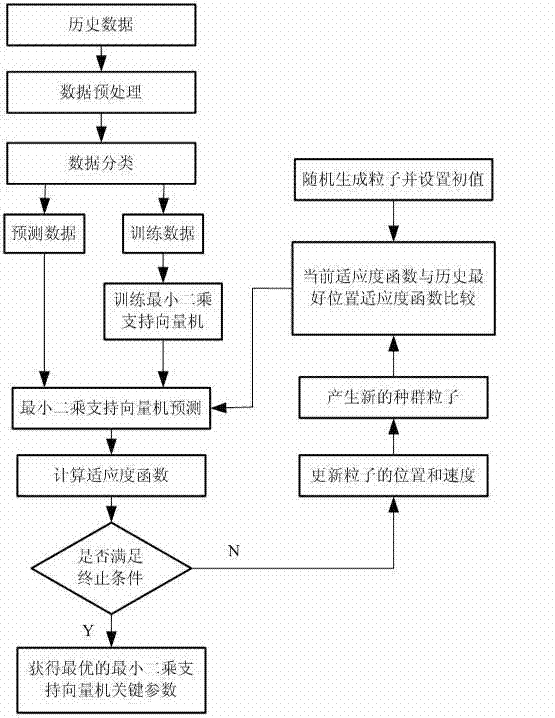

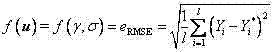

[0024] figure 1 Shown is a schematic diagram of the basic structure of the optimization modeling method of the flux linkage soft sensor instrument based on the least squares support vector machine during the stable suspension operation of the bearingless asynchronous motor. This figure shows the flux linkage least squares support vector machine of the bearingless asynchronous motor The basic framework and composition of soft gauge instrumentation optimization modeling. figure 2 It is a flow chart of optimizing the least squares support vector machine flux linkage soft sensor instrument model based on the improved particle swarm algorithm, which specifically describes the optimization process. The implementation of the invention is divided into two parts, the first part is the least square support vector machine modeling of the flux linkage of the bearingless asynchronous motor. In order to achieve the best regression effect of the built model, the second part is to determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com