TCSC (thyristor controlled series compensator) and SVC (static var compensator) joint debugging control system and working method based on saddle node bifurcation theory

A control system and joint debugging technology, applied in flexible AC transmission systems, reactive power adjustment/elimination/compensation, AC networks to reduce harmonics/ripples, etc., and can solve problems such as large interaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

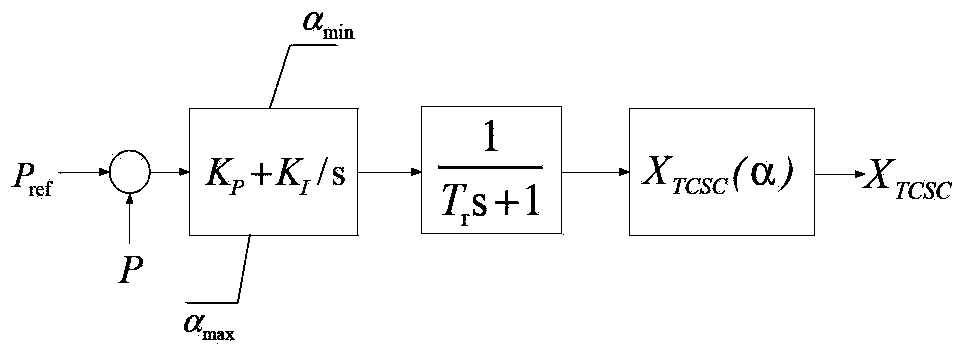

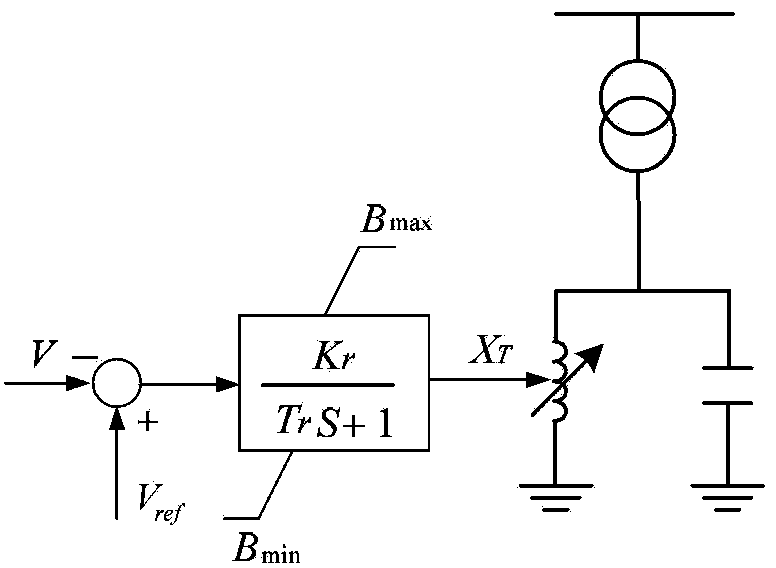

Method used

Image

Examples

Embodiment

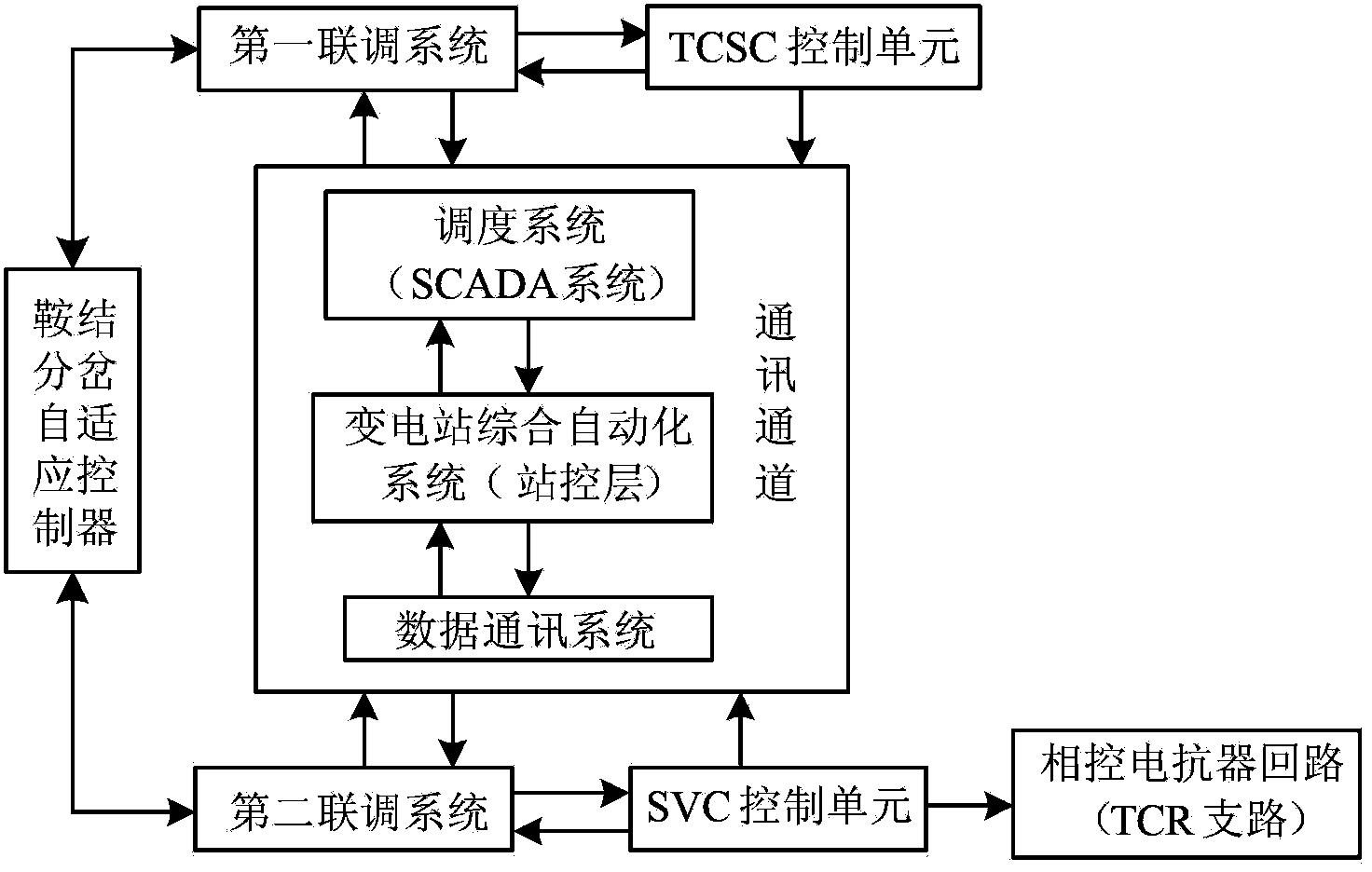

[0062] Embodiment: a kind of TCSC and SVC joint debugging control system based on saddle-node bifurcation theory (see image 3), characterized in that it includes a saddle node bifurcation adaptive controller, a communication channel, a TCSC control unit, an SVC control unit, a TCR branch of a phase-controlled reactor circuit, a first joint control system and a second joint control system; Wherein, the TCSC control unit is bidirectionally connected to the first joint commissioning control unit, and its output terminal is connected to the input terminal of the communication channel; the communication channel is bidirectionally connected to the first joint commissioning control unit and the second joint commissioning control unit respectively connected, and its input end is also connected to the output end of the SVC control unit; the SVC control unit is bidirectionally connected to the second joint debugging control unit, and its output end is connected to the input end of the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com