Surface-mounted permanent magnet synchronous motor magnetic steel seamless assembling apparatus and assembling and repairing processes

A technology of permanent magnet synchronous motor and assembly device, which is applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of large repulsion force and difficult assembly, and achieve the effects of easy implementation, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

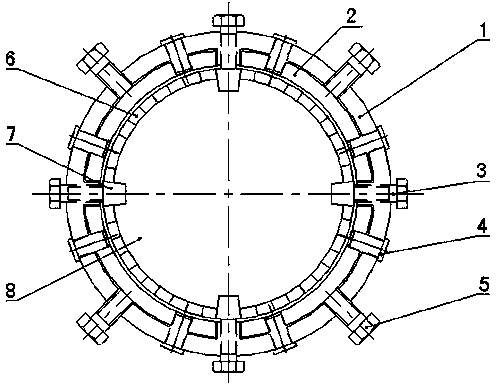

[0034] Such as figure 1 As shown, the surface-mounted permanent magnet synchronous motor magnetic steel seamless assembly device includes a positioning part and a pressing part. The positioning part is a hollow metal outer ring 1, and the metal outer ring 1 is concentric with the rotor core 8. , the metal outer ring 1 is fixedly installed on the magnetic isolation strip 7 of the rotor core 8 through fastening bolts 3, the pressing part is an arc plate 2, and the arc plate 2 is concentric with the metal outer ring 1, and the The arc plate 2 is attached to the inner side of the metal outer ring 1 in the radial direction, and the two are flexibly connected by pins 4. The magnetic steel 6 is installed between the arc plate 2 and the rotor core 8. The metal outer ring 1 is There are threaded holes in the radial direction, and transmission bolts 5 are arranged in the threaded holes to withstand the arc plate.

[0035] As a further implementation of this embodiment, a return spring ...

Embodiment 2

[0037] The difference between embodiment 2 and embodiment 1 is that the transmission parts between the metal outer ring 1 and the arc plate 2 are different. In embodiment 1, bolts are used. A bearing is provided, the bearing is embedded in the back of the arc plate 2, one end of the screw passes through the threaded hole provided on the metal outer ring 1 and is fixed in the center of the bearing, and the other end of the screw is provided with a handle , so that the advance and retreat of the arc plate can be directly controlled by rotating the handle.

[0038] The magnet seamless assembly process of the surface-mounted permanent magnet synchronous motor utilizing the above magnet seamless assembly device includes the following steps:

[0039]S11. Install the positioning part, pressing part and transmission part on the rotor core, and adjust the distance between the pressing part and the rotor core so that it is consistent with the thickness of the magnetic steel or 1-3mm gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com