Energy consumption brakingbraking device and method for servo driver

A technology of servo drive and energy-consumption braking, applied in the direction of stopping devices, etc., can solve the problems of reducing the service life and work performance of the servo drive, torque ripple, etc., to improve stability and work performance, stabilize the bus voltage, improve The effect of work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

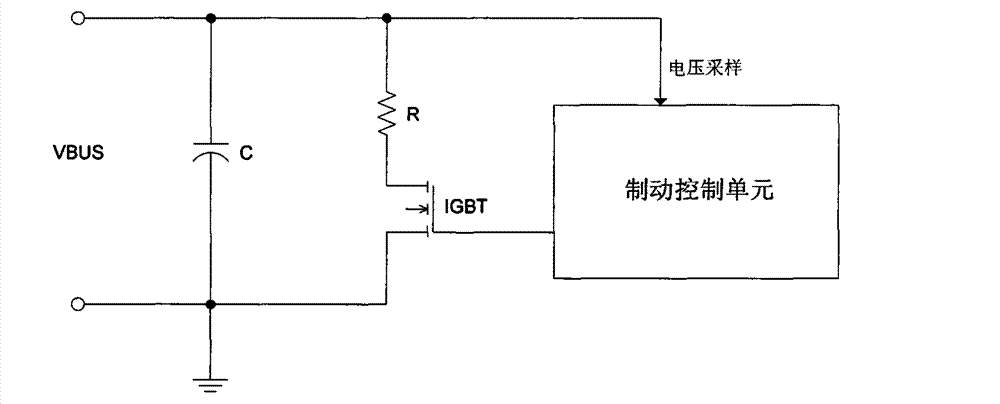

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

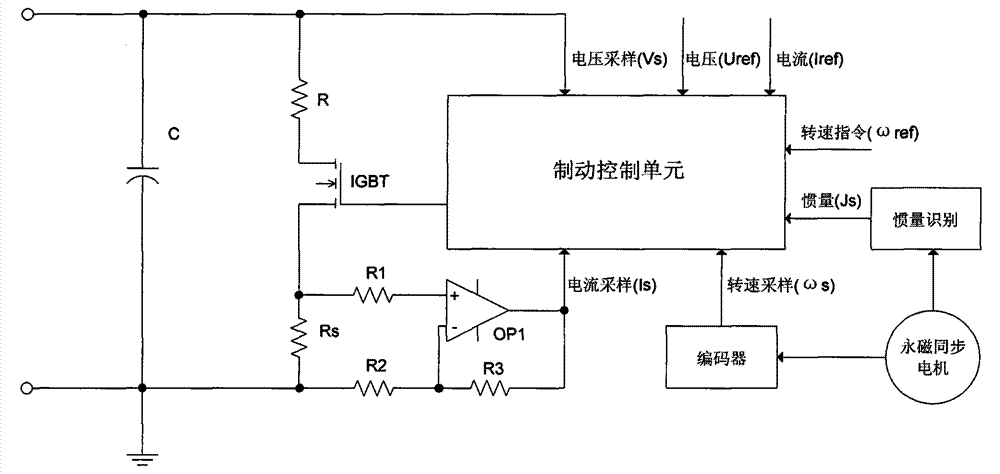

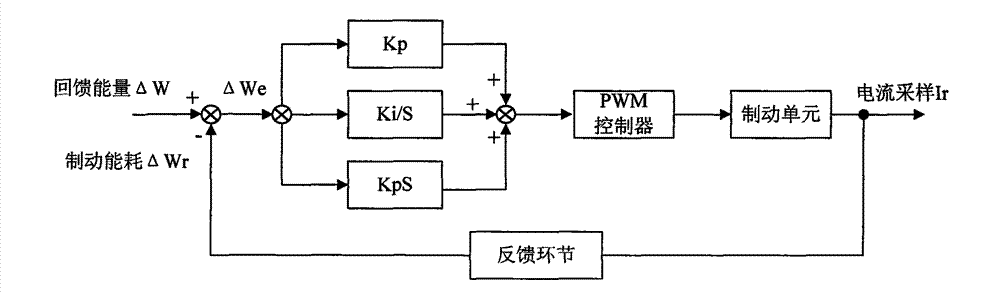

[0040] The circuit block diagram of energy consumption braking unit of the present invention is as figure 2As shown, the current sampling, speed output and inertia identification modules are added to the traditional dynamic braking unit, where the speed output includes the operating speed ωs and the given speed ωref, and the corresponding control algorithm is pre-calculated to obtain a feedback energy value At the same time, during the speed change process, the vector control adjustment module is sampled in real time and the Iref and Uref of each unit time interval are calculated. From Iref and Uref, another value ΔW2 of the feedback energy can also be calculated, and the feedback energy ΔW1 and After ΔW2 is weighted, the feedba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com