Polarizing layered film, polarizing plate and method for producing the same

A technology of laminating films and polarizing plates, applied in polarizing elements, nonlinear optics, optics, etc., can solve the problems of insufficient polarization performance of polarizing plates and insufficient contrast of display devices, and achieve the effect of good dyeing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

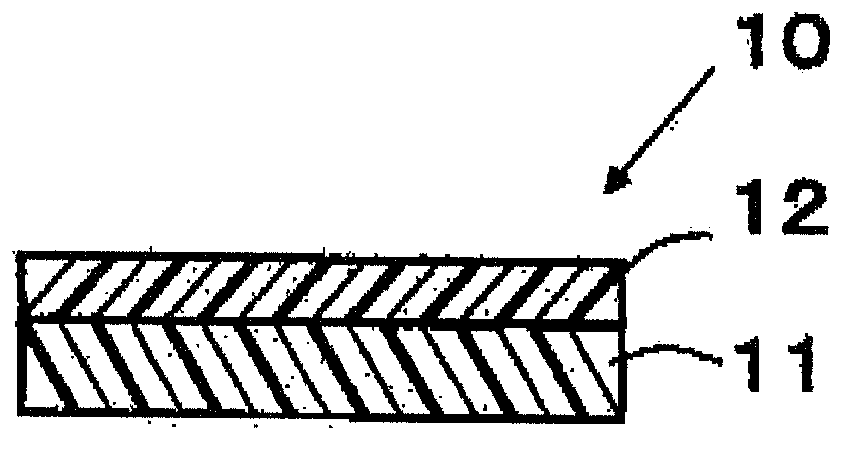

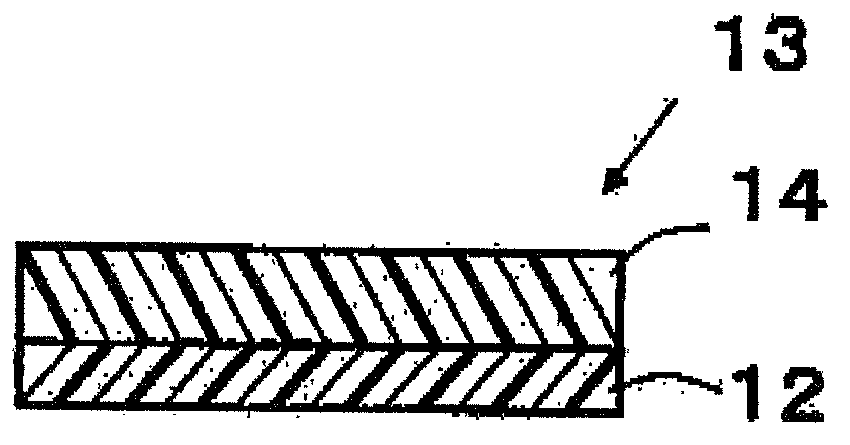

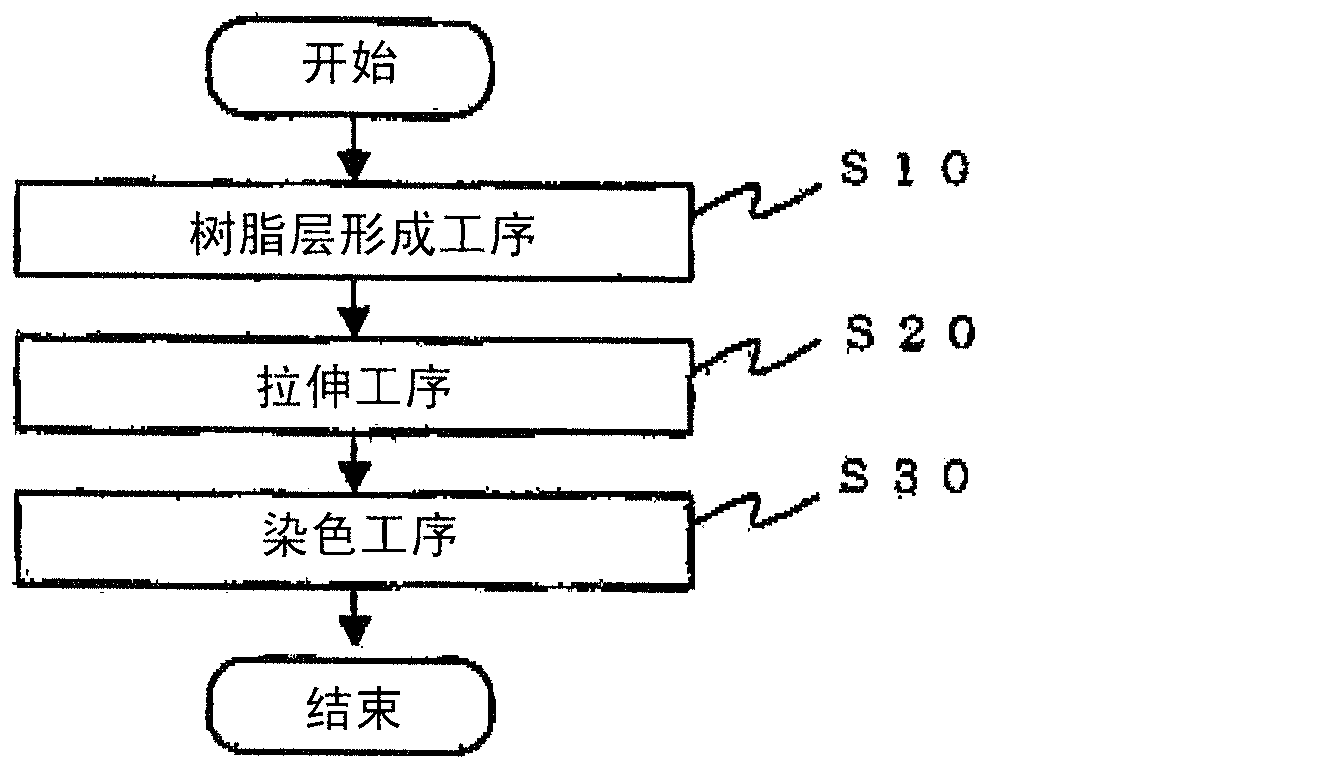

[0133] according to Figure 4 The manufacturing method shown, making as figure 2 The polarizing plate shown.

[0134] (substrate film)

[0135] As the base film, an unstretched polypropylene (PP) film (melting point: 163° C.) having a thickness of 110 μm was used.

[0136] (undercoat layer formation process)

[0137] Polyvinyl alcohol powder (manufactured by Nippon Synthetic Chemical Industry Co., Ltd., average degree of polymerization 1100, degree of saponification 99.5 mol%, trade name: Z-200) was dissolved in hot water at 95°C to prepare a concentration of 3% by weight. aqueous solution. In the obtained aqueous solution, 5 parts by weight of a crosslinking agent (manufactured by Sumitomo Chemical Co., Ltd., trade name: SUMIREZ (registered trademark) RESIN 650) was mixed with respect to 6 parts by weight of polyvinyl alcohol powder.

[0138] The obtained mixed aqueous solution was coated on a corona-treated substrate film using a micro-gravure coater, and dried at 80° ...

Embodiment 2

[0156] As the polyvinyl alcohol used in the resin layer, polyvinyl alcohol powder (manufactured by Nippon Synthetic Chemical Industry Co., Ltd., average degree of polymerization 2200, degree of saponification 97.5 to 98.5 mol%, trade name: AH-22) was used, except that , A stretched film was obtained by the same method as in Example 1. The thickness of the resin layer in the stretched film was 5.5 μm. In addition, the dyeing process, bonding process, peeling process, etc. were carried out by the same method as in Example 1, thereby obtaining the polarizing film of Example 2 formed of four layers: a protective film, an adhesive layer, a polarizer layer, and a primer layer. plate. The thickness of the polarizer layer was 5.6 μm.

Embodiment 3

[0158] As the polyvinyl alcohol used in the resin layer, use polyvinyl alcohol powder (JAPAN VAM & POVAL CO., LTD. manufacture, average polymerization degree 2600, saponification degree 95.5~97.5 mol%, trade name: JM-26), except this aspect Except for this, a stretched film was obtained by the same method as in Example 1. The thickness of the resin layer in the stretched film was 5.3 μm. Furthermore, the dyeing process, lamination process, peeling process, etc. were carried out by the same method as in Example 1, thereby obtaining the polarizing plate of Example 3 formed of four layers: a protective film, an adhesive layer, a polarizer layer, and an undercoat layer. . The thickness of the polarizer layer was 5.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com