Carbon fiber and basalt composite filtering material

A composite filter and carbon fiber technology, which is applied in the direction of filter separation, layered products, chemical instruments and methods, etc., can solve the problems of large strength loss and achieve the effect of improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the technical solution of the present invention will be described in detail in conjunction with the drawings and embodiments of the specification:

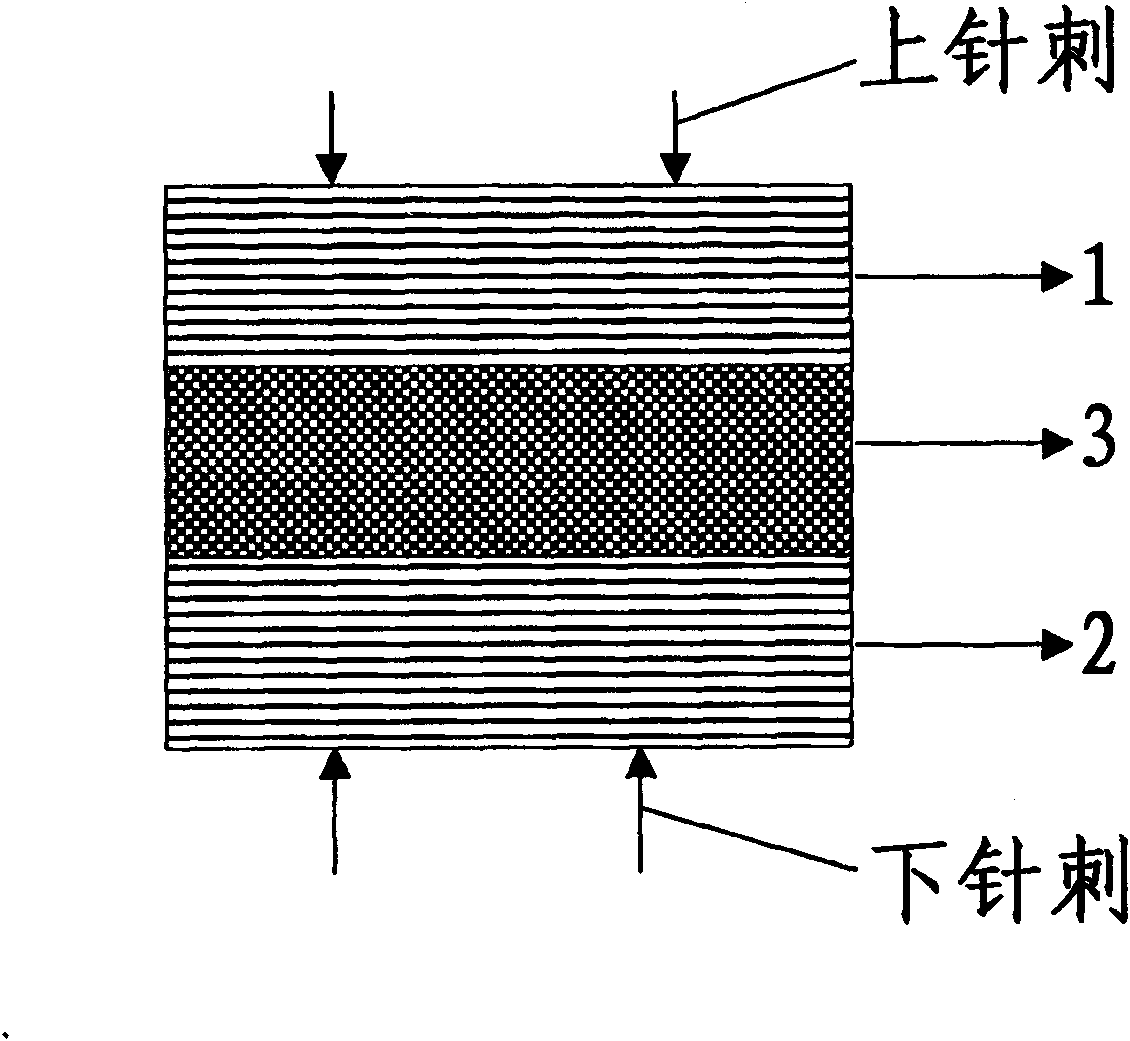

[0018] A carbon fiber basalt composite filter material of the present invention is composed of an upper composite fiber felt layer 1, a lower composite fiber felt layer 2 and a middle base cloth layer 3, the upper composite fiber felt layer 1, the middle base cloth layer 3, and the lower composite fiber felt layer 2 and the intermediate base cloth layer 3 are composited into one body through the lower needle punching process and the upper needle punching process respectively. The above-mentioned intermediate base cloth layer 3 is a mesh cloth woven with 1K carbon fiber through a rapier machine, and the upper composite fiber felt layer 1 and the lower composite fiber felt layer 2 are made of 50% carbon fiber chopped strands and 25% stainless steel short strands. Cut shreds and 25% basalt fiber chopped shreds are mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com